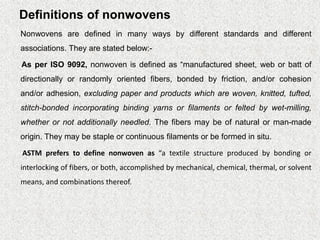

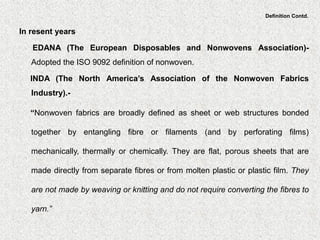

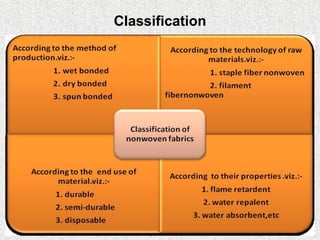

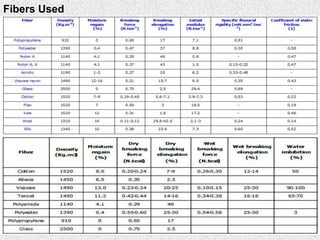

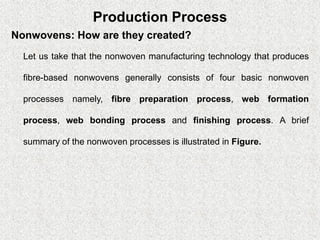

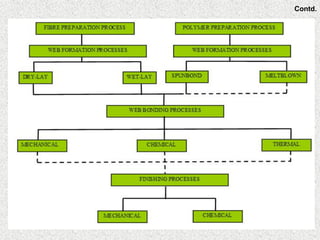

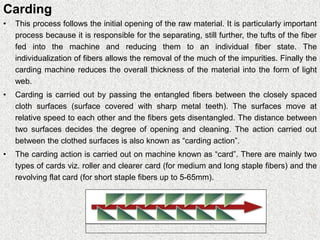

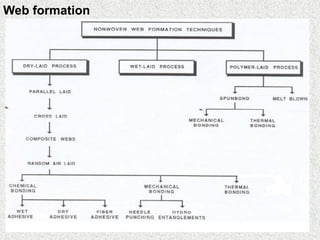

The document provides an overview of non-woven processes. It defines non-wovens and discusses their classification based on fiber type and production process. The major production processes include carding, air laying, spunbonding, meltblowing, needlepunching, and hydroentangling. These processes involve fiber preparation, web formation, bonding, and finishing. Non-wovens find applications in products like diapers, wipes, filters, insulation, and geotextiles due to their engineered properties. In conclusion, the document discusses opportunities for further innovation and economic study in the non-woven industry.

![References

i. Batra, S., Pourdeyhimi, B., Shiffler, D., TT 305 Fibre Web and Nonwoven Production, Desk

Copy, North Carolina State University, USA, 2004.

ii. Neckar, B. and Das, D., Theory of structure and mechanics of fibrous assemblies, Woodhead

Publishing India Ltd., New Delhi, 2011.

iii. Simmonds, G. E., Bomberger, J. D., Bryner, M. A., Designing nonwovens to meet pore size

specifications, Journal of Engineered Fibres and Fabrics 2 (1), 1-15, 2007.

iv. K allmes, O. and Corte, H., TAPPI 43 (9), 737-752, 1960.

v. [1] Morton W. E. and Hearle, J. W. S., Physical properties of textile fibers, Woodhead Publishing

Ltd., UK, 2008.

vi. [2] Albrecht, W., Fuchs, H., and Kittelmann, W., Nonwoven fabrics: Raw materials, manufacture,

applications, characteristics, testing processes, Wiley-VCH, 2002 (Edited).

vii. [3] Russel, S. J., Handbook of nonwovens, Woodhead Publishing Ltd., 2006 (Edited).

viii. [4] Vaidya, N., Pourdeyhimi, B., Shiffler, D., The manufacturing of wet-laid hydroentangled glass

fibre composites: Preliminary results, International Journal of Nonwovens 2003, 55-59.](https://image.slidesharecdn.com/non-wovenmpd-converted-signed-200418151847/85/Non-woven-Process-39-320.jpg)