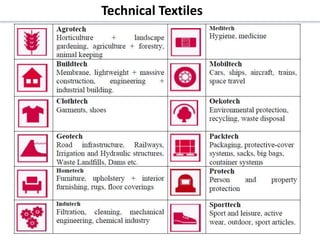

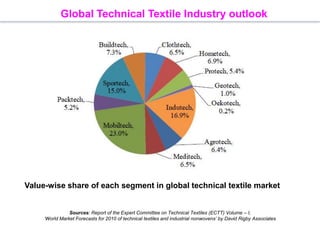

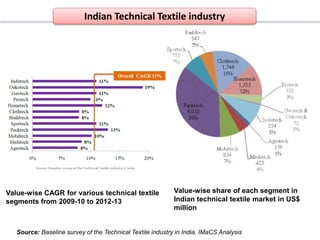

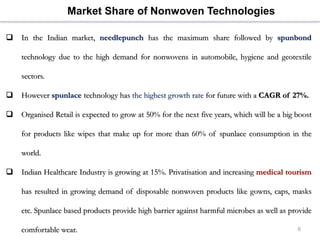

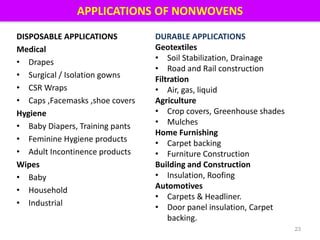

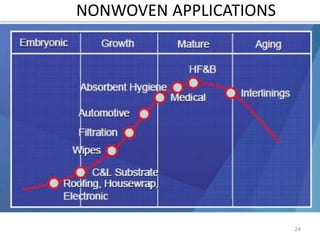

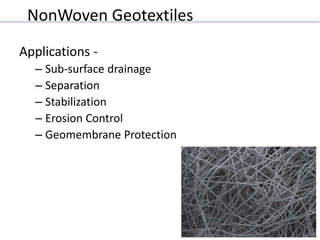

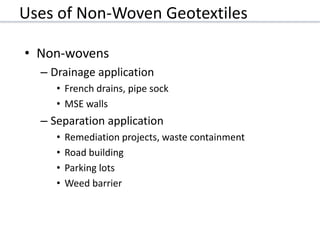

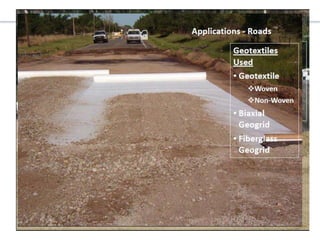

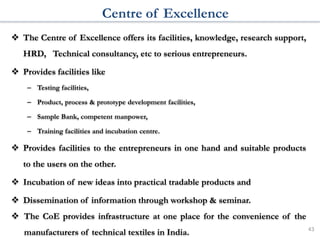

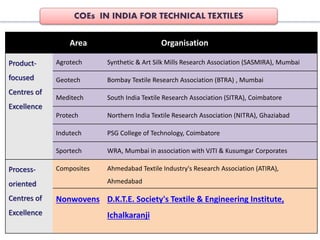

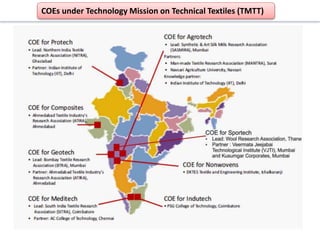

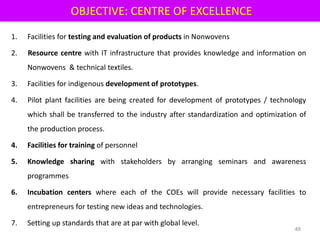

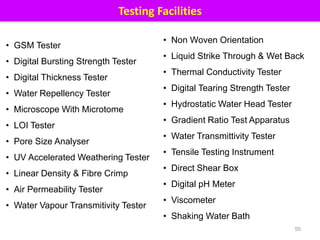

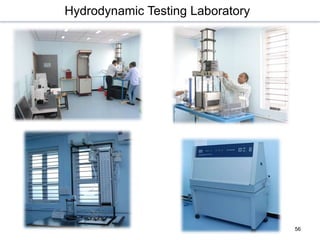

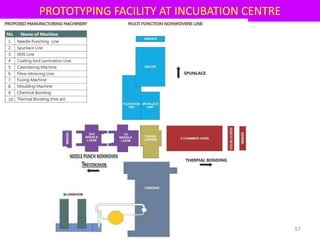

This document provides an overview of the Indian nonwoven industry and the future prospects of nonwoven technologies. It discusses the various segments of the technical textile industry and their growth rates. Needlepunch currently has the largest market share in India, while spunlace is expected to grow the fastest. The document also outlines various applications of nonwovens in areas like agriculture, construction, home furnishings, automotive, packaging and more. It then describes the activities of DKTE Centre of Excellence in Nonwovens, which includes testing facilities, prototyping facilities, training programs, seminars, and R&D activities to support the nonwoven industry.