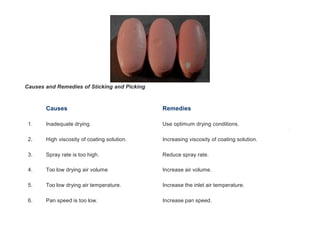

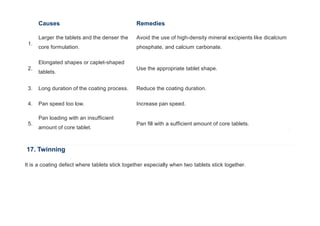

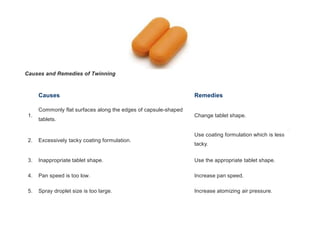

The document discusses tablet coating defects and remedies. It begins by introducing tablet coating as the final step in tablet production where a coating is applied to provide benefits like masking taste or protecting the tablet. It then lists and describes 18 common coating defects like blistering, blooming, chipping and provides the likely causes and remedies for each. The defects cover issues with the coating appearance, adhesion, and protection. The document aims to help formulation scientists identify and address coating problems to successfully complete tablet production.

![Tablet Coating Defects and Remedies

Menu

March 4, 2023

Tablet coating defects and remedies are the crucial concern of a pharmaceutical formulation scientist. The last

critical step in the tablet production cycle is tablet coating after solving problems in core tablet manufacturing.

After finding the tablet coating defects and their remedies, you will successfully complete the tablet production

cycle. So, read this article about tablet coating defects and remedies to identify and solve your coating

problems.

Tablet coating is the application of a coating composition in a moving bed of tablets with the concurrent use of

heated air to facilitate the evaporating of the solvent [1] and with the intention of conferring benefits and

properties to the dosage form over the uncoated variety. Mainly, tablet coating is to be done for masking

unpleasant tastes and odors, protection, identification, improvement of patient compliance, and delivery to the

targeted part of GIT. For a proper coating on tablets, a formulator must know about the following tablet coating

defects and their remedies.

Table of Contents](https://image.slidesharecdn.com/tabletcoatingdefectsandremedies-240313143339-5d2a7187/75/Tablet-Coating-Defects-and-Remedies-pptx-1-2048.jpg)