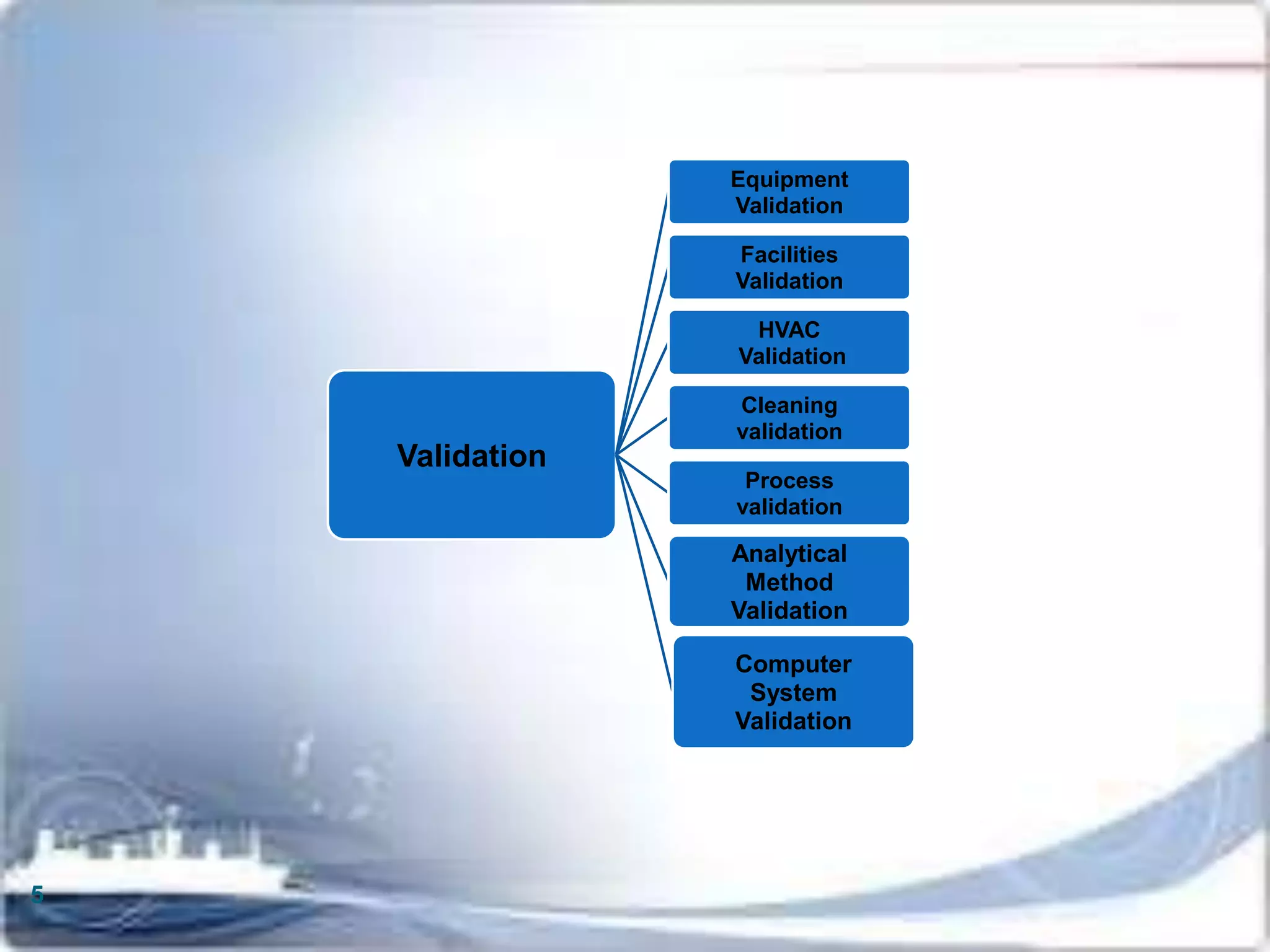

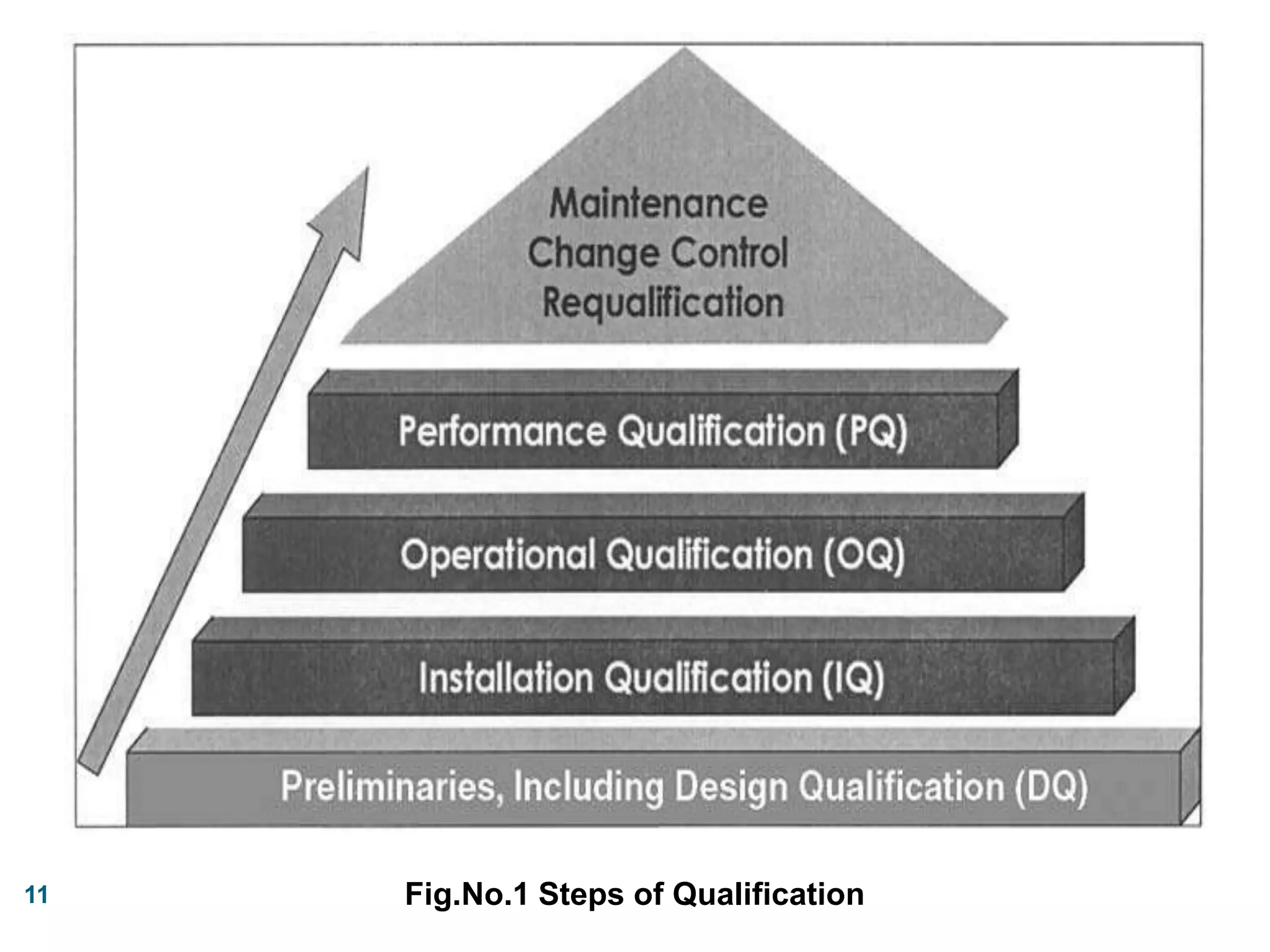

This document discusses the validation of dissolution test apparatus. It begins with a brief history of validation and reasons for validating equipment. Validation ensures equipment operates consistently and accurately. The document then discusses various types of dissolution test apparatus and the qualification process, including design, installation, operational, and performance qualification. It also addresses sources of error and concludes that acceptable qualification demonstrates the apparatus is validated for use in dissolution testing.

![METHODS

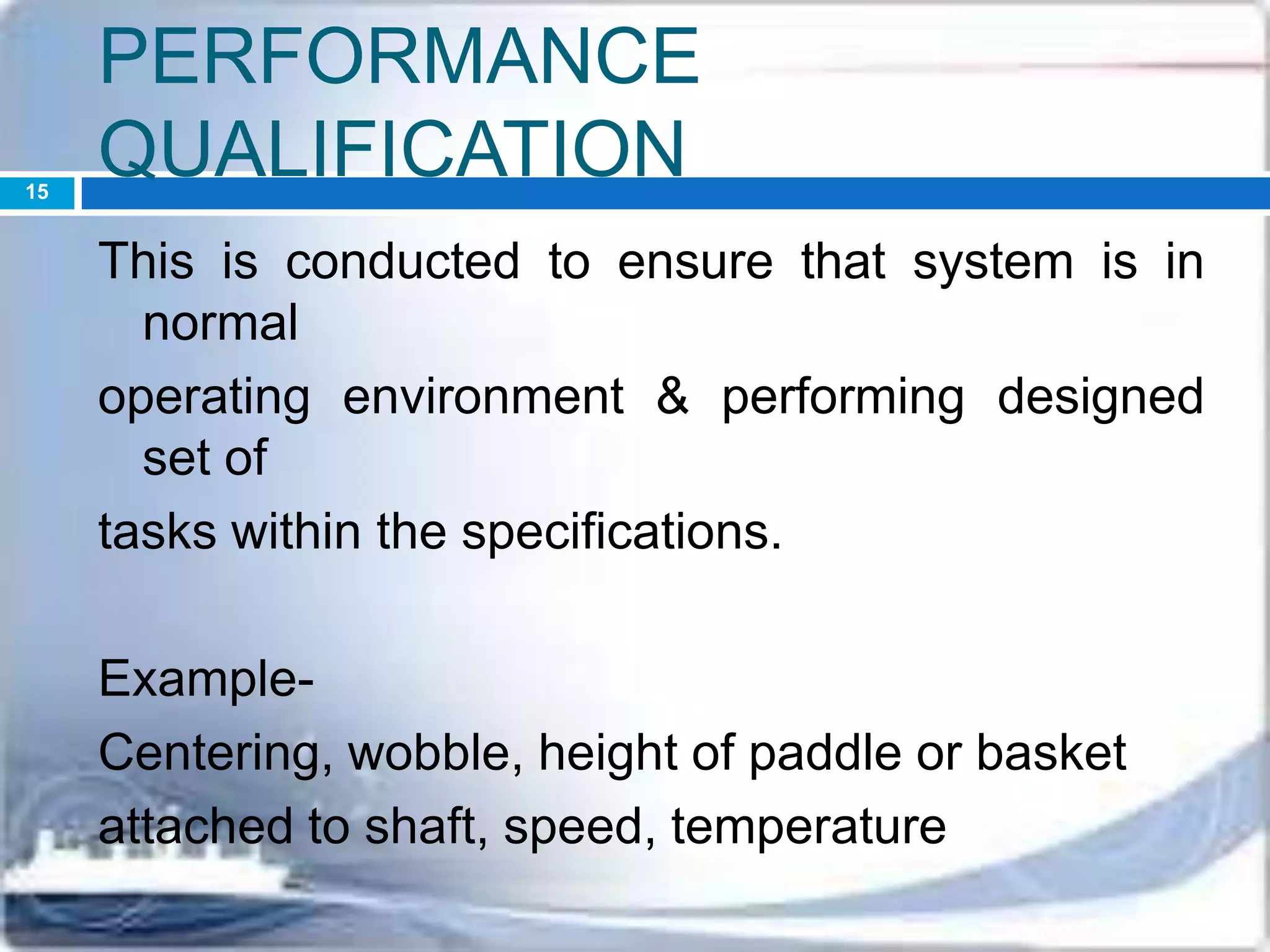

A] Calibration

Non-compendial & some compendial apparatus

do not have calibrator tablets, in some case in

house calibrator tablets are designed.

Some unique aspects of equipment can only be

detected with USP calibrated tablets, there are

no practical measuring tools available for

analyst. e.g. vibration and vessel

irregularities.

20](https://image.slidesharecdn.com/validationofdissolutionapparatus-140409075234-phpapp01/75/Validation-of-dissolution-apparatus-20-2048.jpg)

![B] HYDRODYNAMICS

Dissolution fluid flow should be free from

irregularities

or variable turbulence.

Highly variable data may be unsuitable for that

product.

C] OTHER CONSIDERATIONS-

Ruggedness should be thoroughly evaluated

before

considering transferring product testing to

another site.21](https://image.slidesharecdn.com/validationofdissolutionapparatus-140409075234-phpapp01/75/Validation-of-dissolution-apparatus-21-2048.jpg)

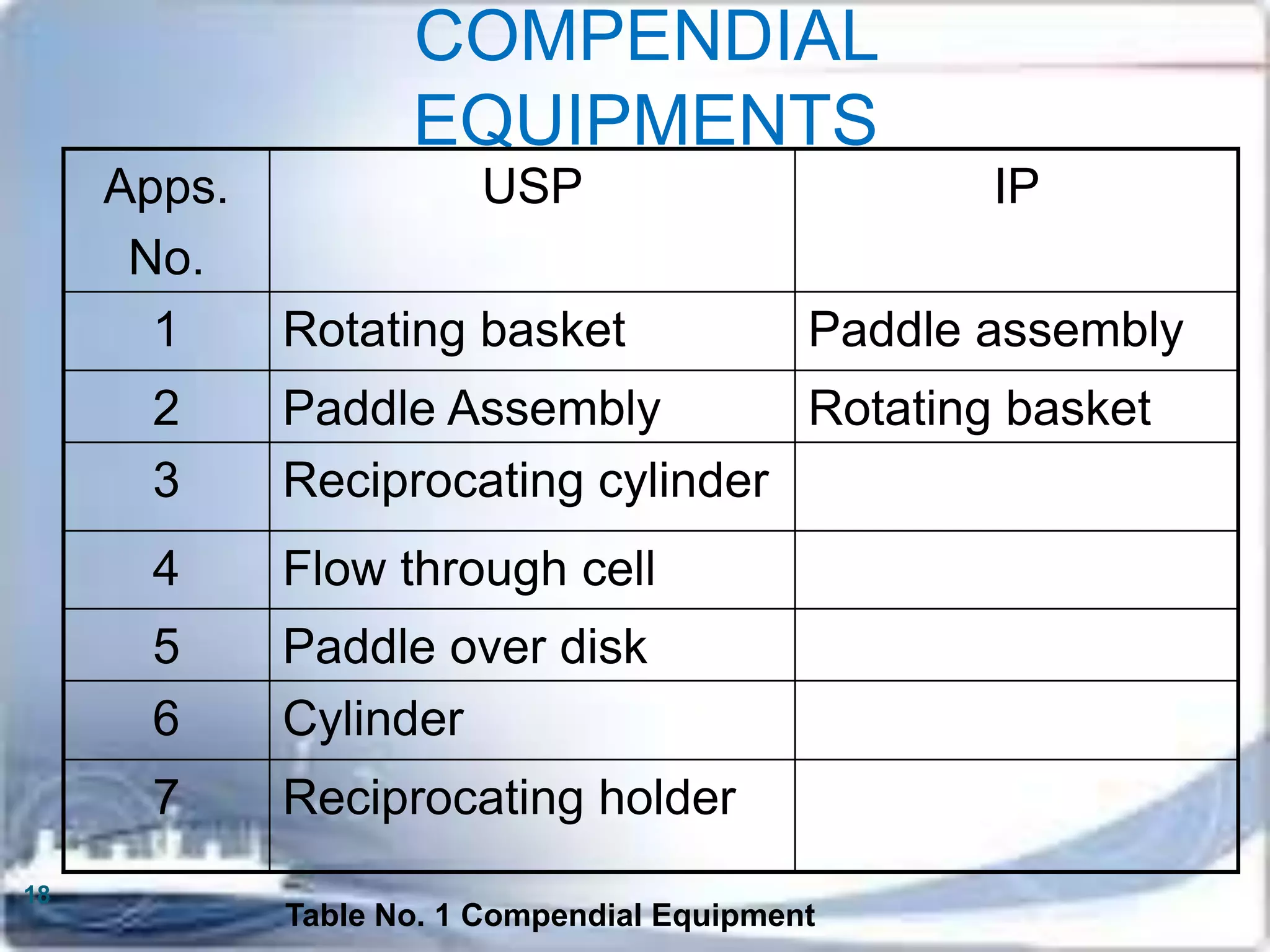

![SOURCES OF ERRORS

A] Drug substance properties

e.g. Solubility, pH

B] Drug product properties

Mechanical, formulation

C] Equipment

Mechanical & chemical aspects, Apparatus suitability test

D] Method consideration

To avoid errors

Film coated tablets-sticky-sinker

Suspension-syringe/pipette/beaker

Medium-volume difference

Presence of surfactants

33](https://image.slidesharecdn.com/validationofdissolutionapparatus-140409075234-phpapp01/75/Validation-of-dissolution-apparatus-33-2048.jpg)

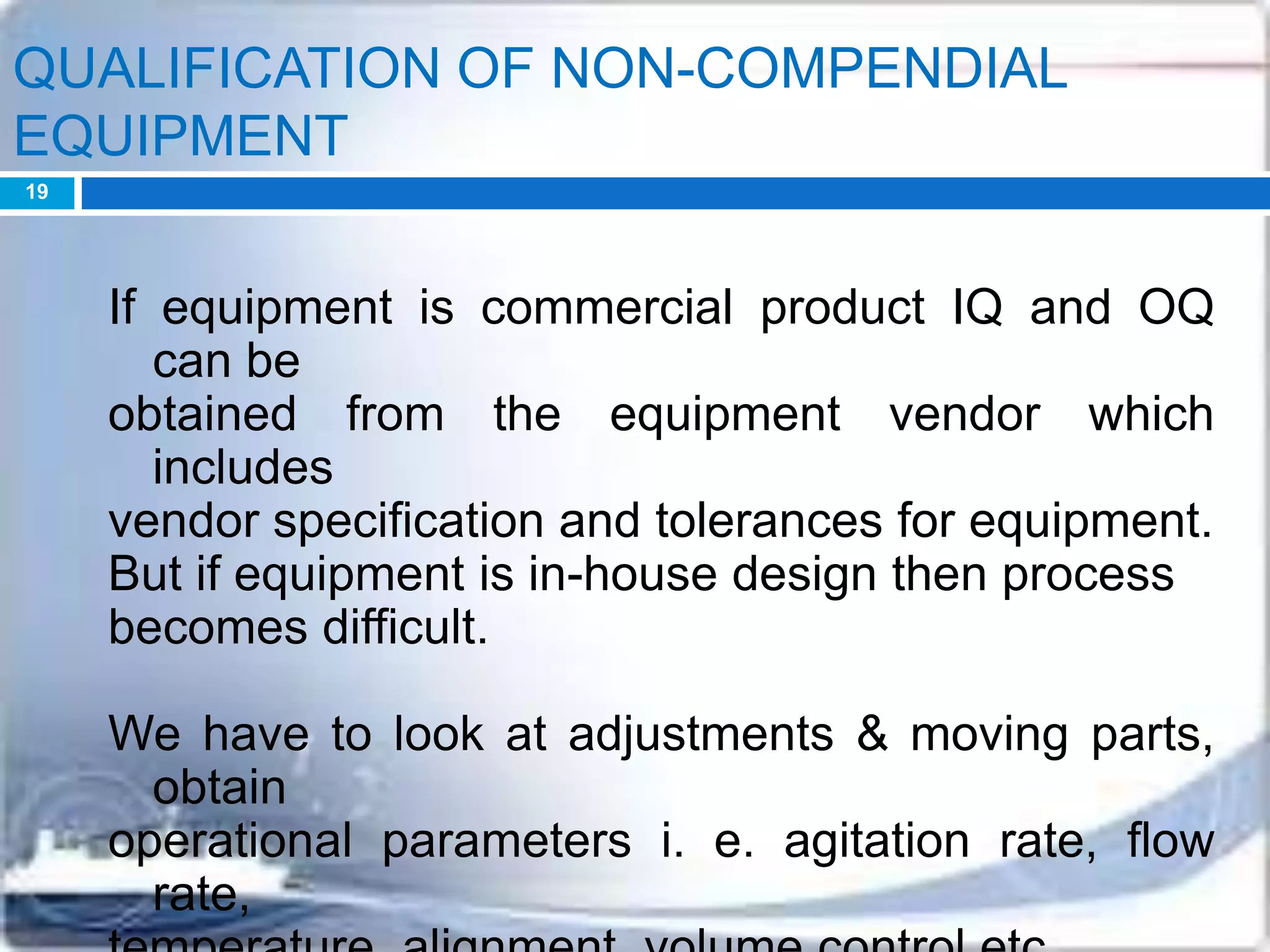

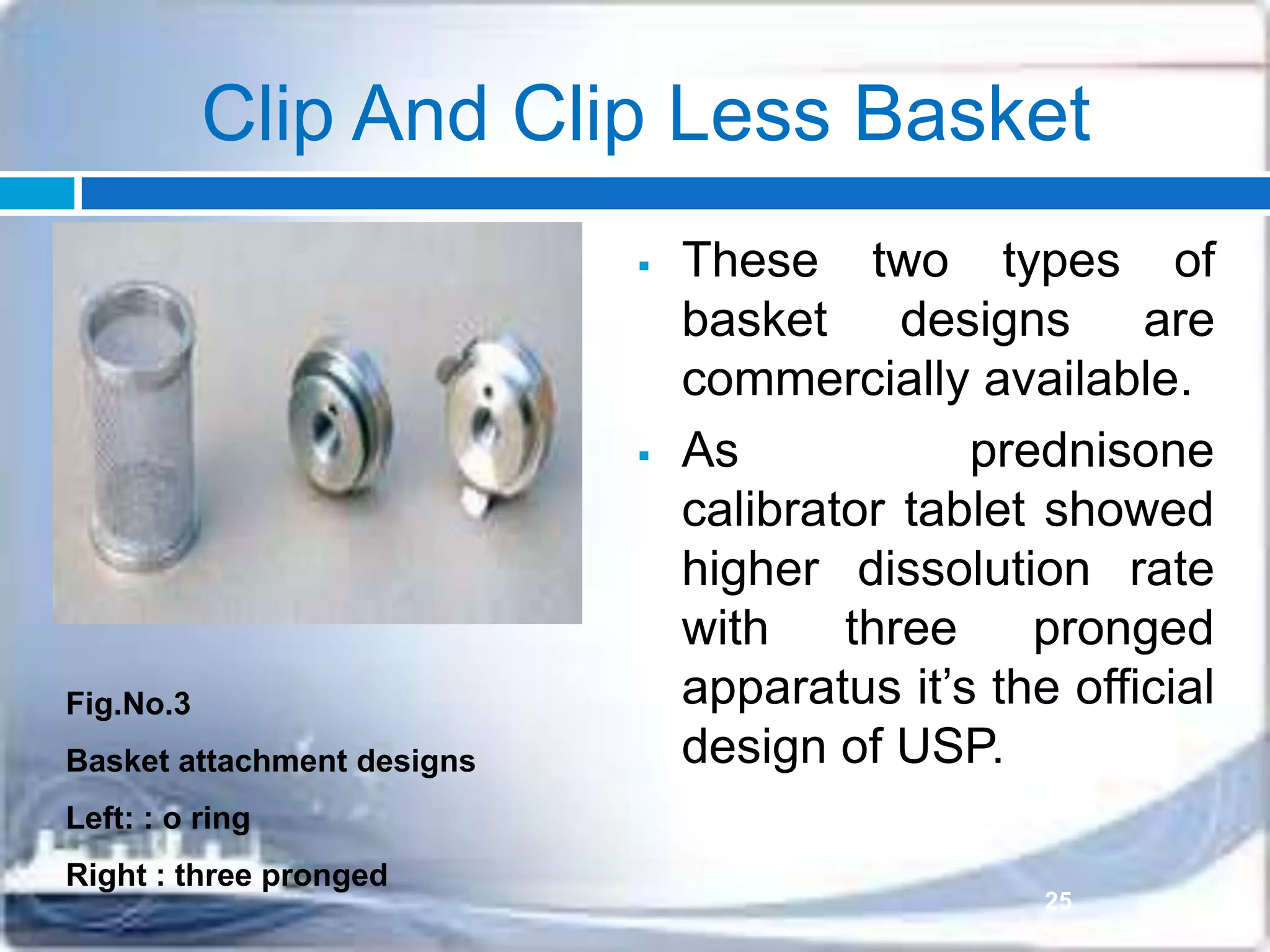

![SOURCES OF ERRORS

E] Observation

Sinkers-turns of wire helix-its effect

Manual sampling

F] Automation

Problems-disconnection, inadequate cleaning, mix-ups

G] Cleaning

Many products, same equipment major source of error

H] Method transfer

Sinkers, dispensing apparatus, sampling methods, precise

medium, standard preparations, grade of reagents

should be uniform.

34](https://image.slidesharecdn.com/validationofdissolutionapparatus-140409075234-phpapp01/75/Validation-of-dissolution-apparatus-34-2048.jpg)