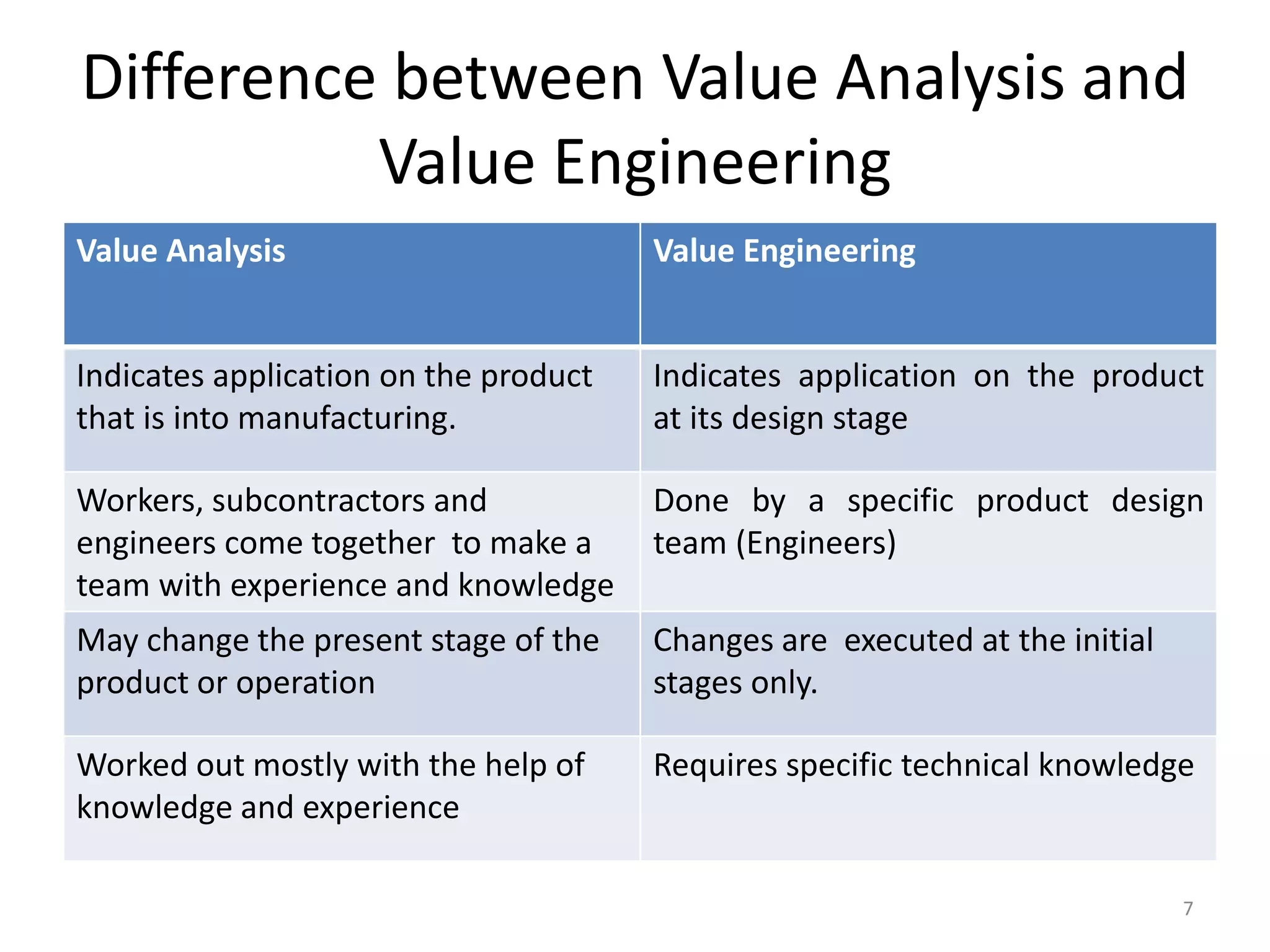

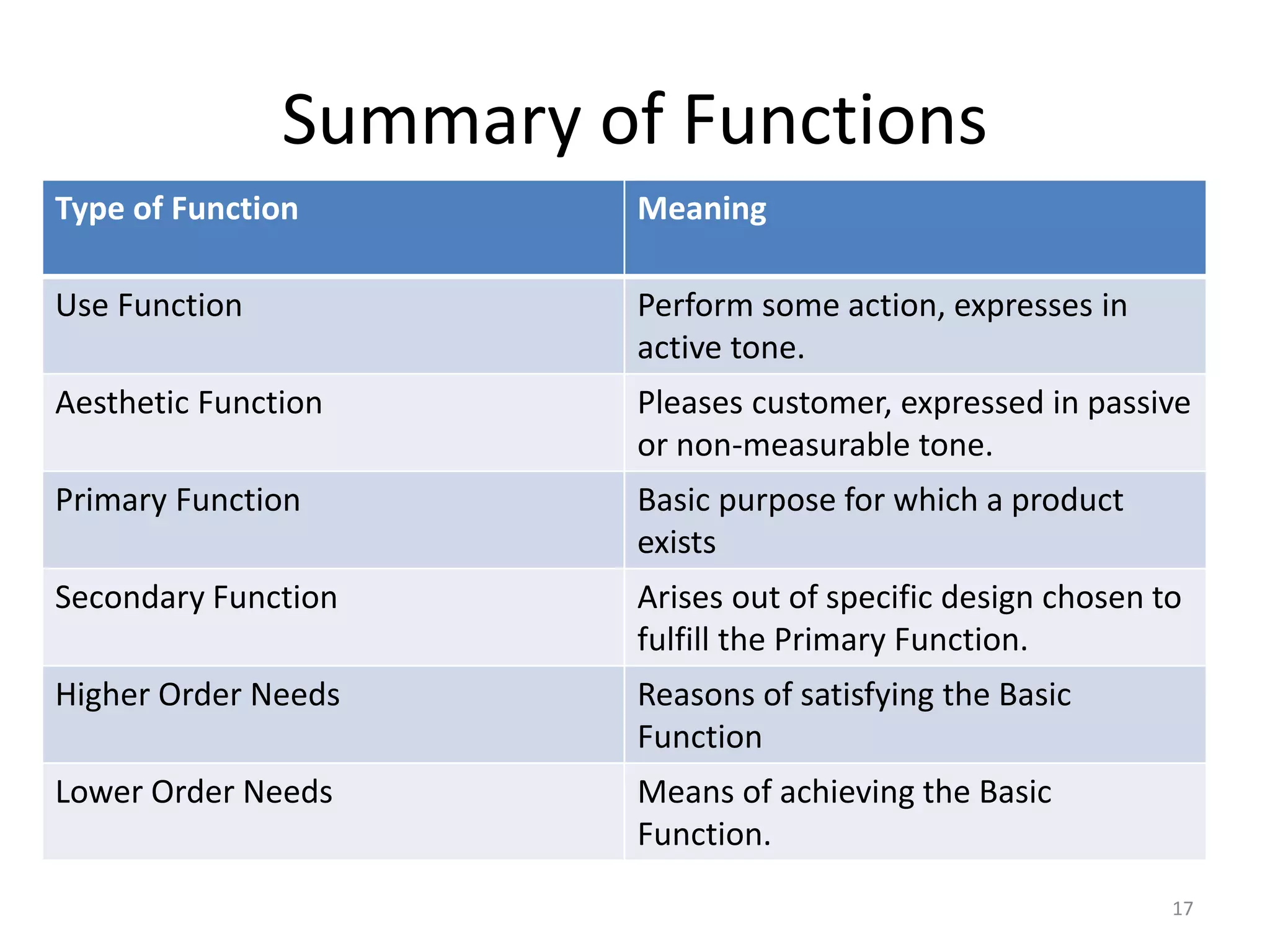

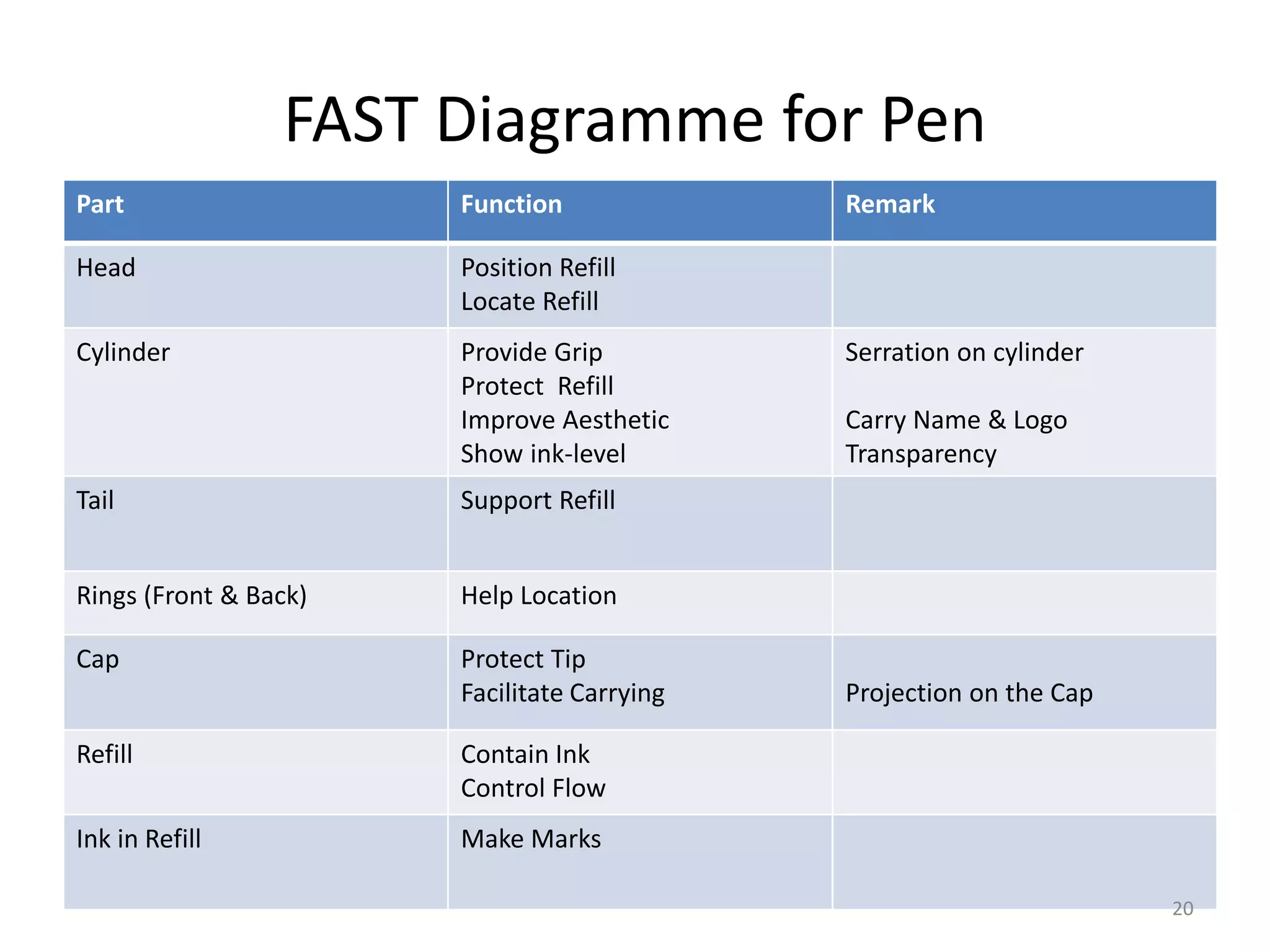

Value analysis and value engineering are techniques used to increase the value of products and services. Value is defined as desired performance divided by overall cost. Value analysis focuses on identifying unnecessary functions and reducing costs without affecting quality or performance. It was developed during World War 2 to substitute materials as supplies became limited. Value engineering applies these principles during the design stage to reduce costs. Both aim to deliver the desired functions at the lowest overall cost.