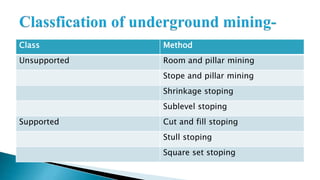

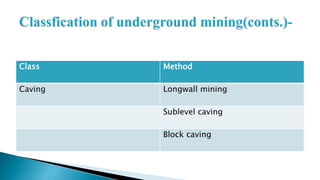

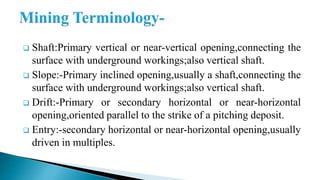

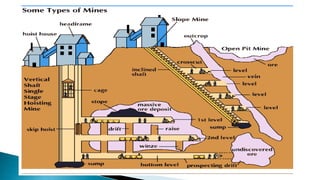

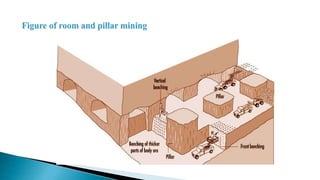

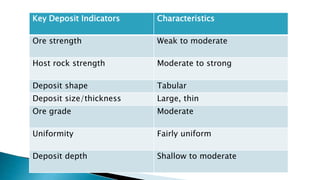

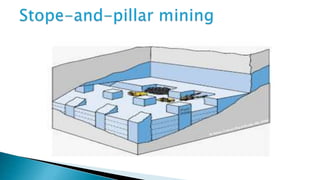

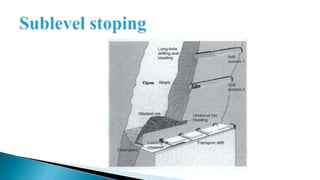

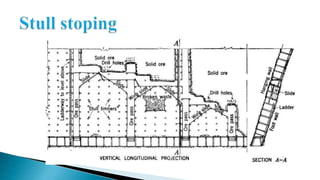

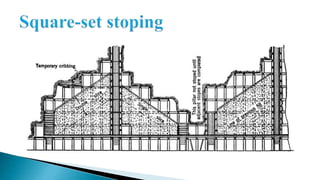

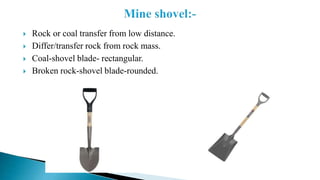

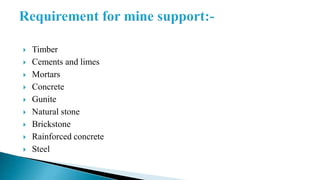

The document provides an overview of underground mining methods. It discusses room and pillar mining, which involves cutting rooms into coal beds and leaving pillars for support. This method is well-suited for flat, narrow deposits. Stope and pillar mining and shrinkage/sublevel stoping are also described. The document outlines various mining equipment used including hand tools, power tools, excavators, and machinery for hauling, loading, and transporting minerals. Factors for selecting a mining method and planning mine development are also summarized.