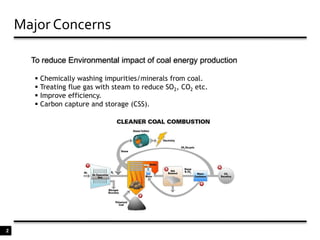

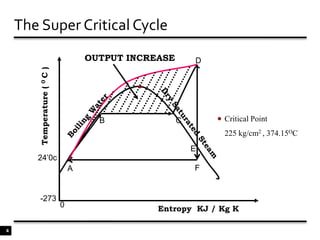

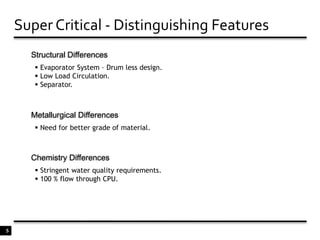

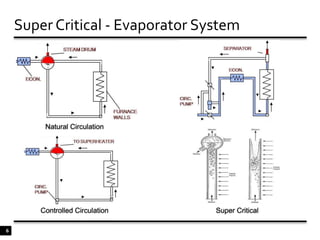

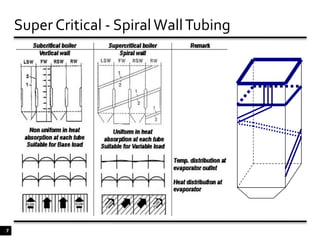

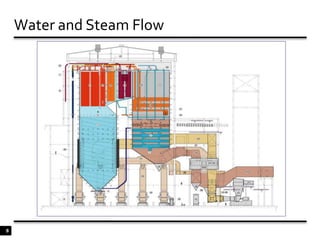

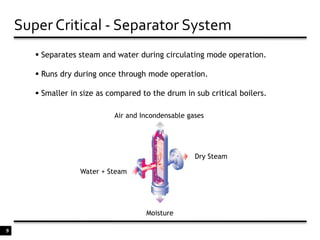

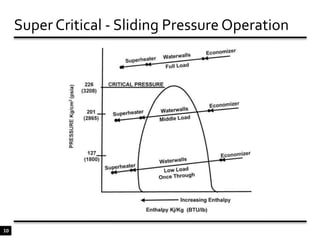

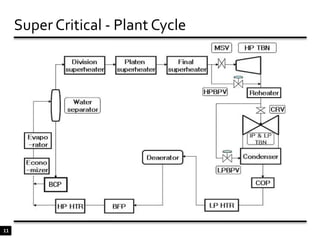

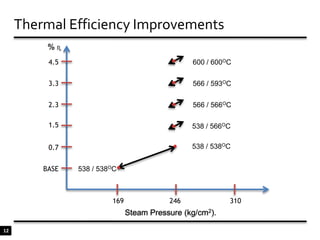

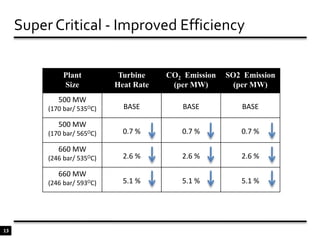

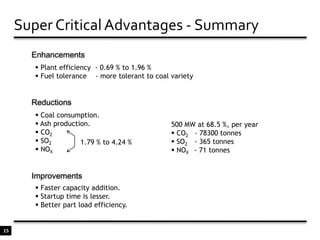

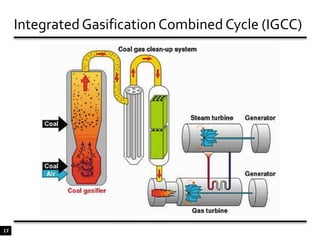

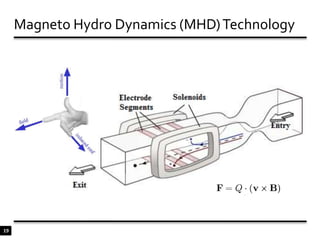

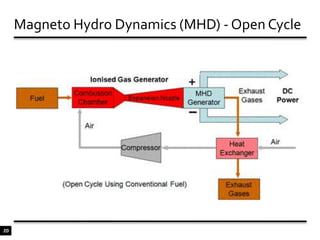

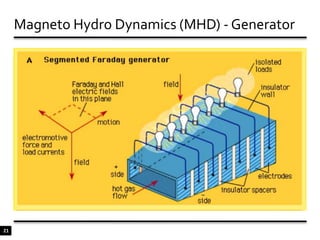

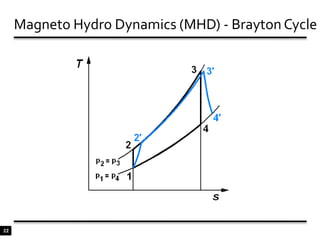

Clean coal technologies aim to reduce the environmental impact of coal energy production through methods like chemically washing coal, treating flue gas to reduce emissions, and carbon capture and storage. The presentation overview discusses supercritical technology, integrated gasification combined cycle (IGCC), and magneto hydrodynamic (MHD) power generation. Supercritical plants operate at a higher temperature and pressure above the critical point for steam, improving efficiency by 0.69-1.96% over subcritical plants. IGCC turns coal into gas before combustion to reduce emissions, but has high costs. MHD generation could achieve efficiencies over 60% by using magnets to directly convert the kinetic energy of ionized gas into electricity in an open Bray