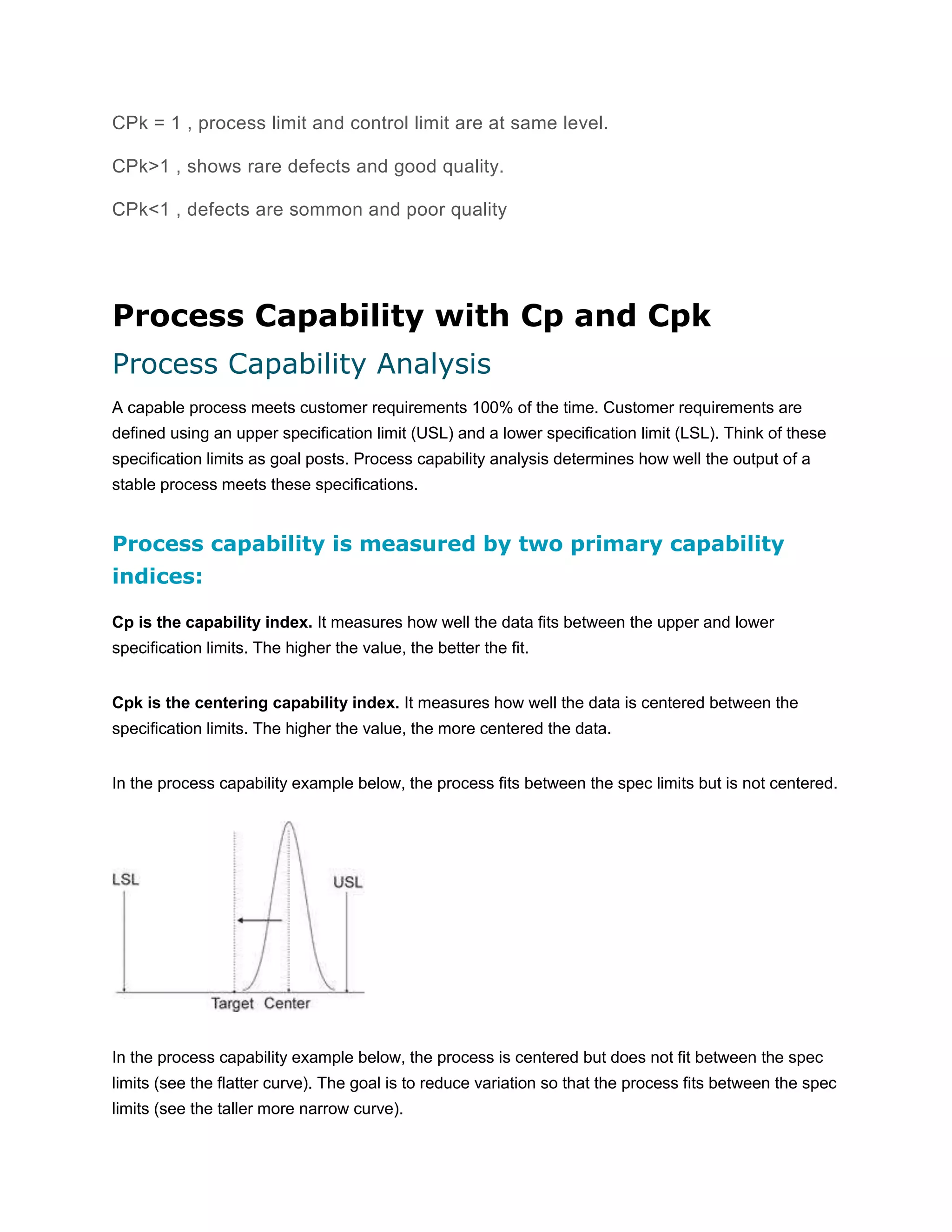

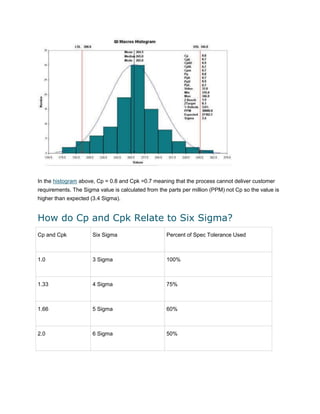

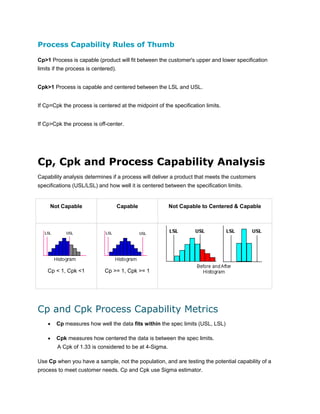

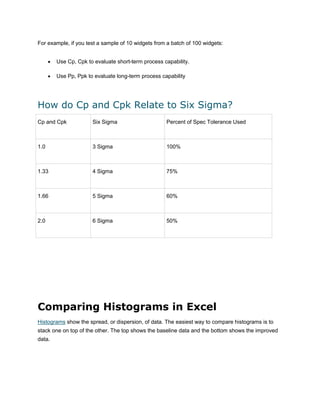

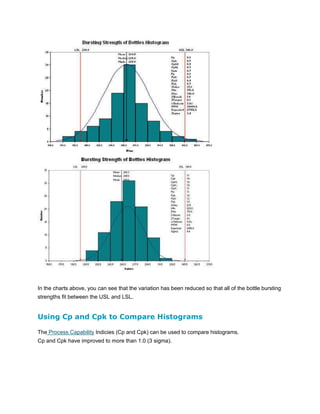

The document discusses process capability analysis using Cp and Cpk metrics. Cp measures how well a process fits within specification limits, while Cpk also considers centering. A Cpk over 1 indicates a capable and centered process. Values over 1.33 represent 4-sigma capability. Cp over 1 but Cpk below 1 means the process is capable but not centered. Histograms and Cp, Cpk values are used to compare baseline and improved processes.