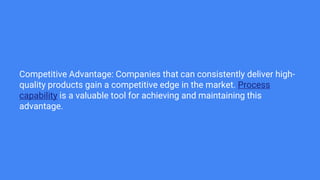

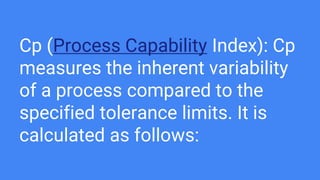

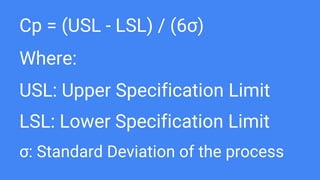

The document discusses the importance of process capability in manufacturing, which is essential for ensuring consistent product quality and meeting customer specifications. It explains the calculation of key indices like Cp and Cpk, which help assess the capability and centering of production processes, ultimately aiding in cost reduction and enhancing customer satisfaction. The article emphasizes that effective process capability management leads to a competitive advantage in the marketplace.

![Cpk = Min [(USL - μ) / (3σ), (μ - LSL) / (3σ)]

Where:

USL: Upper Specification Limit

LSL: Lower Specification Limit

μ: Mean of the process

σ: Standard Deviation of the process](https://image.slidesharecdn.com/understandingprocesscapabilityinmanufacturingakeytoconsistentquality-230914091912-594a9d74/85/Understanding-Process-Capability-in-Manufacturing-A-Key-to-Consistent-Quality-17-320.jpg)