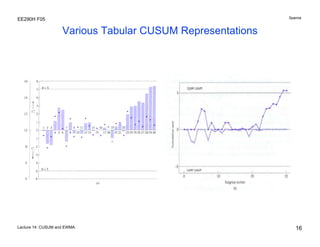

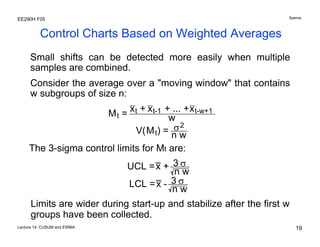

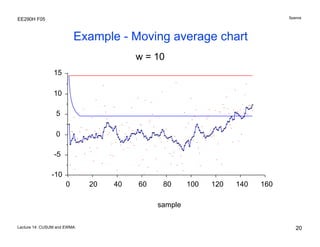

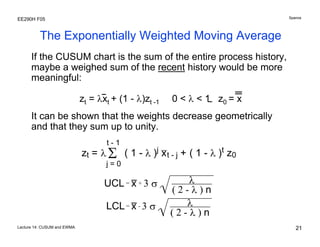

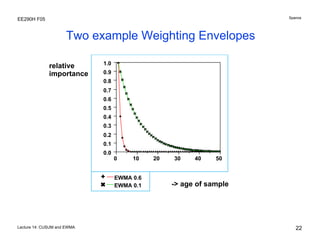

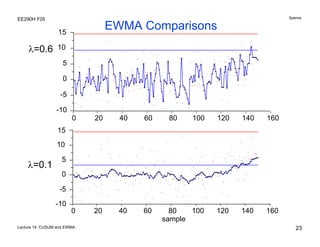

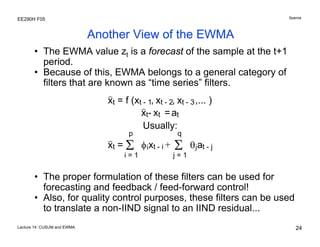

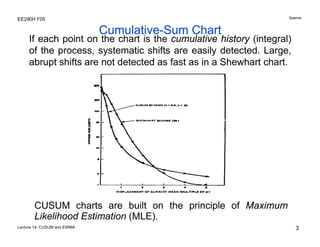

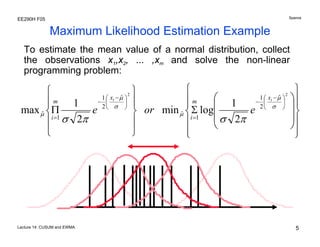

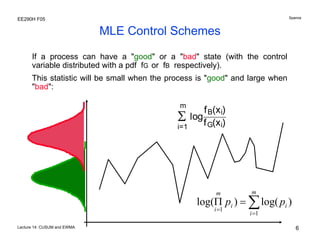

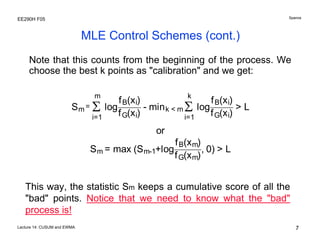

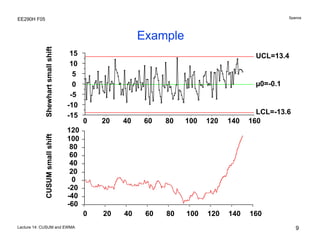

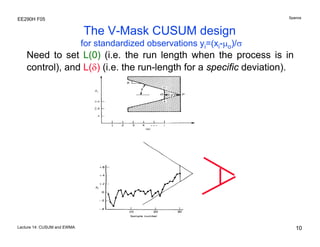

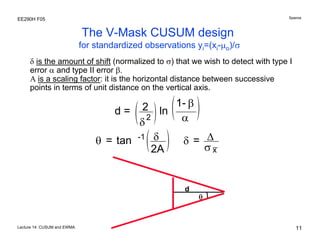

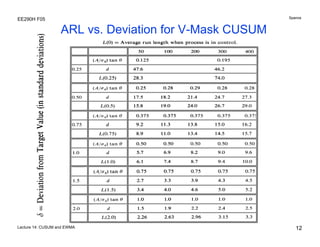

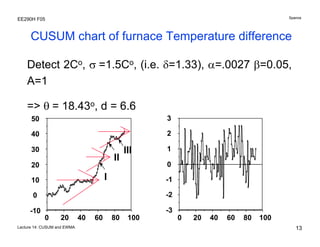

The document discusses various statistical process control charts for detecting small shifts in processes, including CUSUM (Cumulative Sum) charts and EWMA (Exponentially Weighted Moving Average) charts. CUSUM charts cumulatively sum process deviations and are more effective at detecting small shifts than Shewhart charts. EWMA charts create a weighted average of recent process data where older data is downweighted using an exponential factor. Both CUSUM and EWMA charts can be designed using maximum likelihood estimation and control limits to balance type I and type II error rates for detecting shifts of a given size.

![Spanos

EE290H F05

Tabular CUSUM

A tabular form is easier to implement in a CAM system

Ci+ = max [ 0, xi - ( μo + k ) + Ci-1+ ]

Ci-

= max [ 0, ( μo - k ) - xi +

h

Ci-1-

]

d

θ

C0+ = C0- = 0

k = (δ/2)/σ

h = dσxtan(θ)

Lecture 14: CUSUM and EWMA

14](https://image.slidesharecdn.com/lecture14cusumandewma-131209144229-phpapp01/85/Lecture-14-cusum-and-ewma-14-320.jpg)