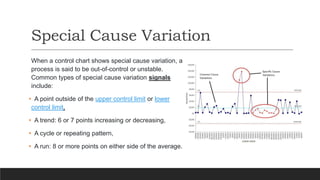

There are two main types of process variation: common cause variation and special cause variation. Common cause variation is due to inherent factors in the system that cause predictable fluctuations. Special cause variation is unexpected and caused by changes to procedures, materials, or tools. Understanding the sources and types of variation is important for process improvement and reducing quality problems.