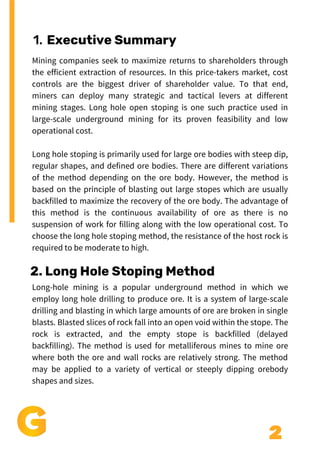

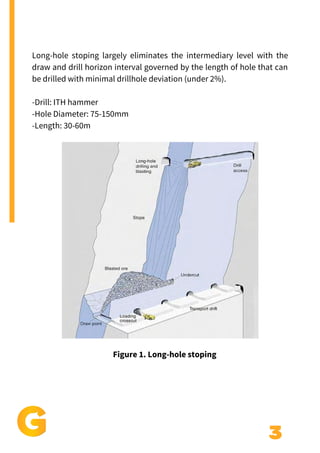

The document outlines best practices for long hole stoping in mining to enhance production efficiency and safety, emphasizing the need for strategic planning and real-time operational visibility. It highlights the advantages and disadvantages of different long hole stoping methods, including transverse and longitudinal approaches, and presents Groundhog's digital solutions for improving operational efficiency through automation, data capturing, and real-time monitoring. Key elements include short interval control and fleet management systems, which help optimize operations and ensure safety within mines.