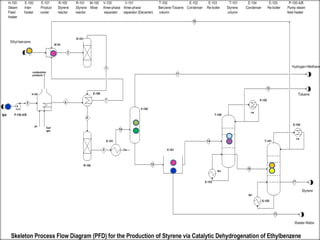

This document discusses the production of styrene via the dehydrogenation of ethylbenzene. Key points include:

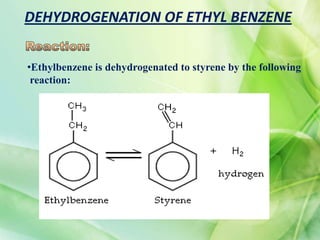

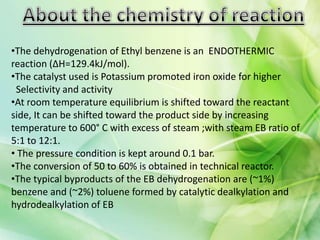

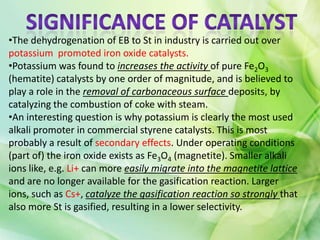

- Ethylbenzene is dehydrogenated to styrene over a potassium promoted iron oxide catalyst at 600°C with steam.

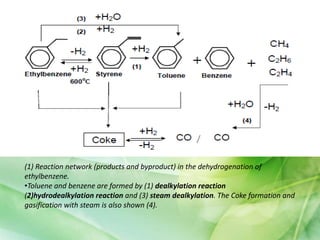

- The main byproducts are toluene and benzene, formed via dealkylation and hydrodealkylation reactions.

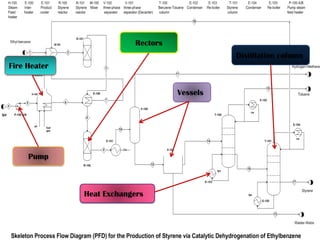

- Styrene production facilities include reactors, distillation columns, vessels, pumps and heat exchangers to carry out the endothermic dehydrogenation reaction and separate/purify the products.

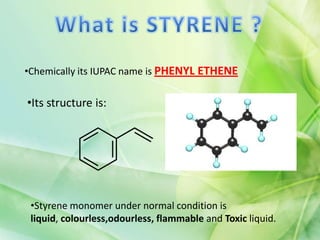

- Safety measures like monitoring air quality and educating employees on spill response are important due to styrene's flammable and toxic