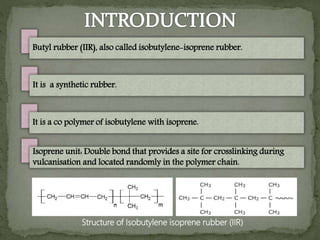

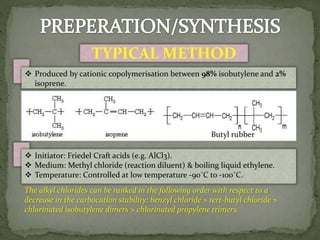

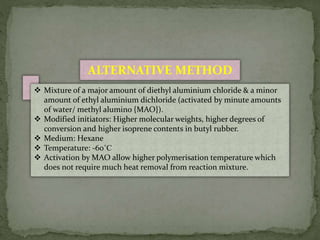

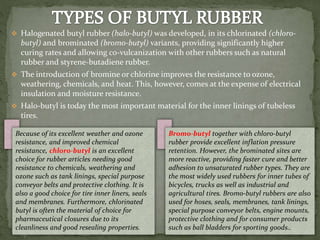

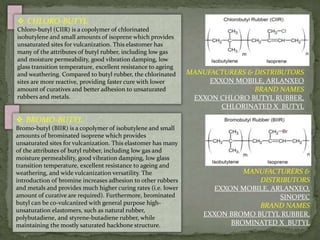

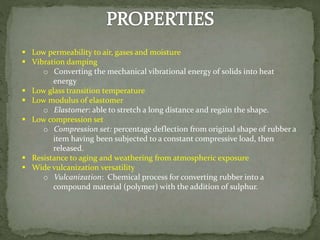

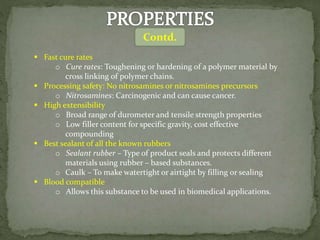

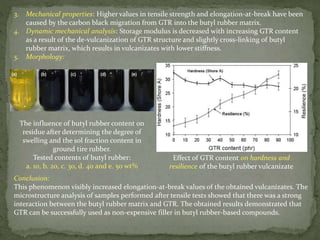

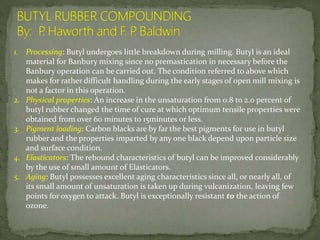

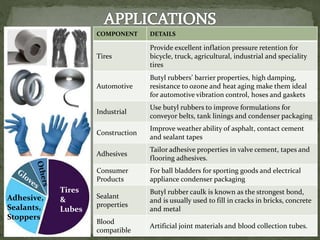

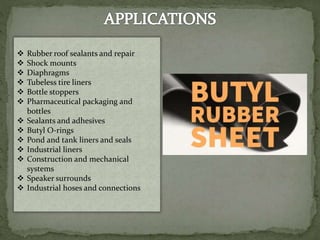

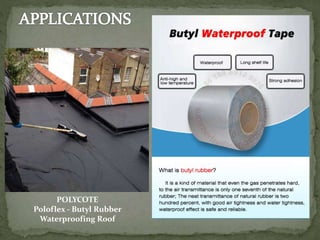

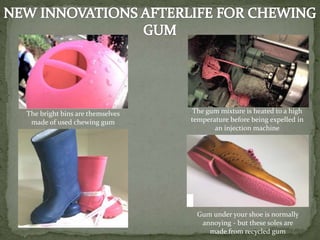

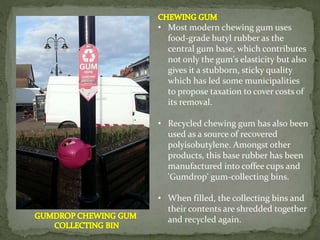

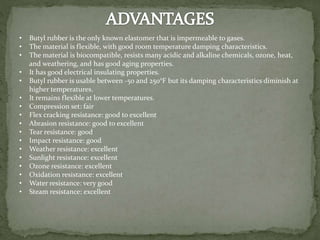

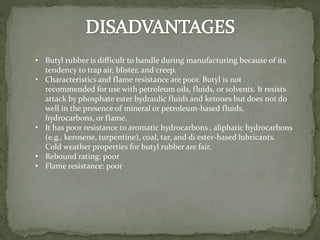

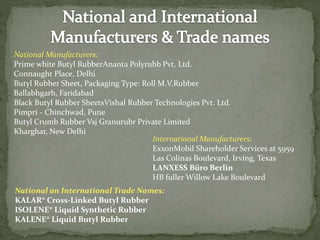

The document discusses isobutylene-isoprene rubber (IIR) and its synthesized variants, including butyl rubber and halo-butyl rubber, highlighting their production methods, properties, and various applications. It details the chemical processes for vulcanization and the influence of additives, including ground tire rubber (GTR), on the mechanical properties of butyl rubber. Furthermore, it explores the extensive use of butyl rubber in consumer and industrial products due to its low permeability, excellent aging resistance, and chemical compatibility.