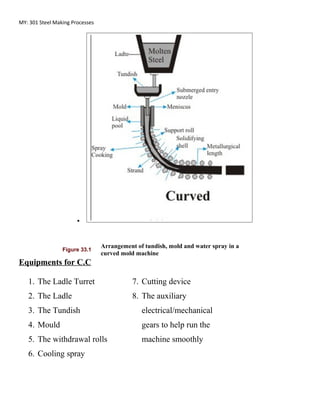

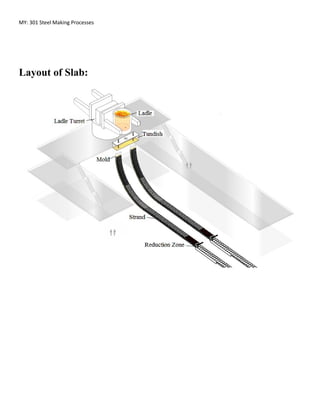

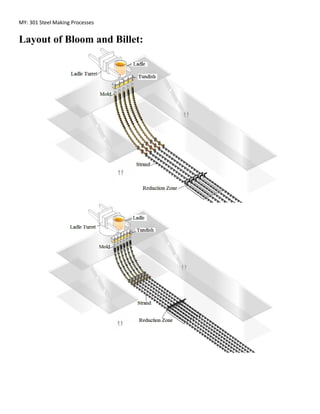

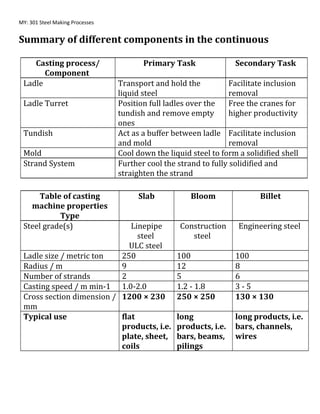

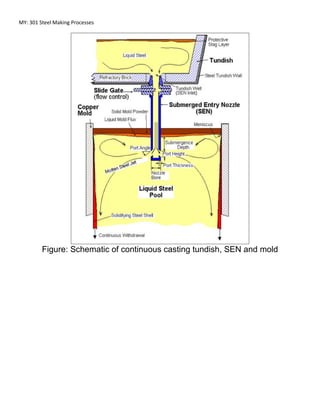

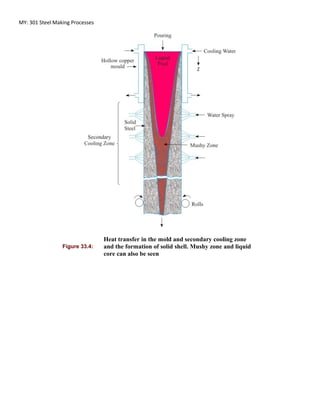

Continuous casting is a steelmaking process where liquid steel is solidified into a semi-finished billet, bloom, or slab. In this process, liquid steel flows from a ladle into a water-cooled copper mold. As the steel exits the mold, it begins to solidify on the surface while the core remains liquid. The semi-solid steel strand is then cooled further through water sprays to fully solidify it into the desired cross-section. The continuous casting process allows for higher productivity and quality than traditional ingot casting.