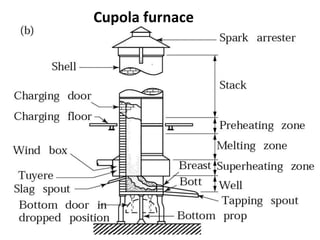

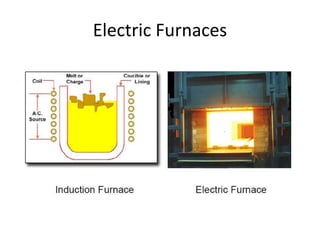

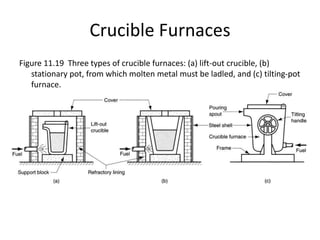

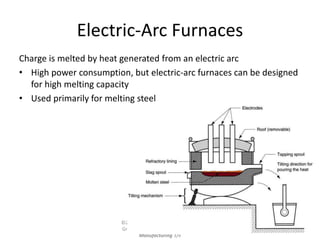

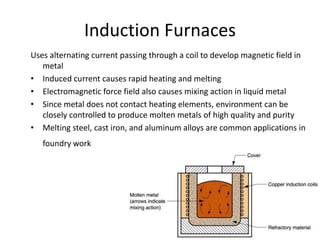

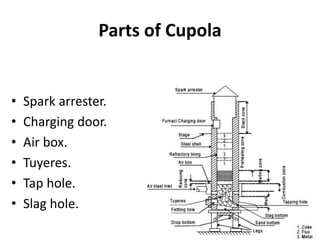

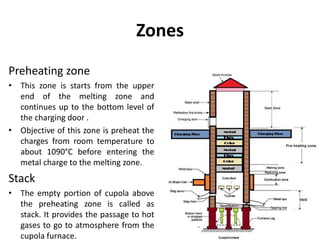

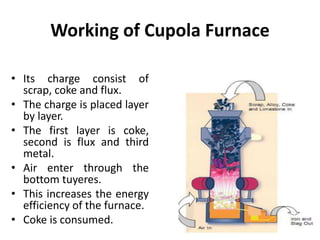

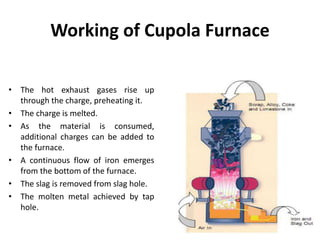

The document discusses different types of furnaces used in foundries for melting metals. It describes cupola furnaces, which are vertical cylindrical furnaces used to melt iron. Cupola furnaces have a charge of coke, metal, and flux layers that are heated by hot exhaust gases rising through the furnace. As the materials are consumed, additional charges can be added. Molten metal emerges from the bottom tap hole while slag is removed from the slag hole. Other furnace types discussed include direct fuel-fired furnaces, crucible furnaces, electric-arc furnaces, and induction furnaces.