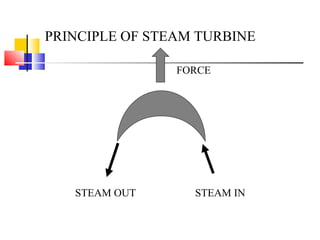

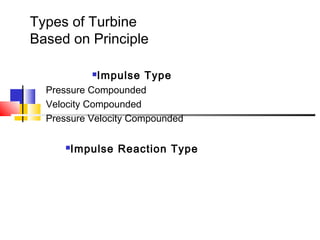

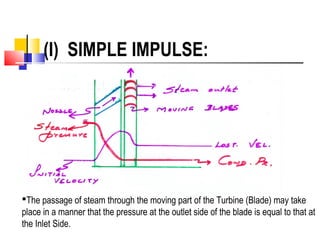

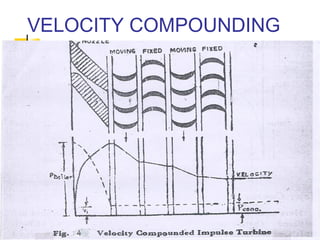

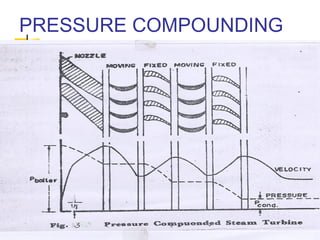

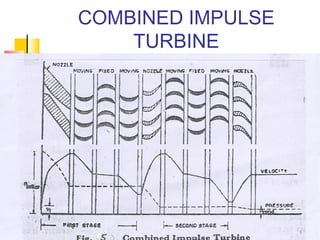

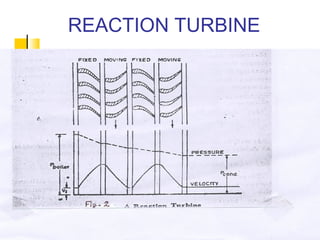

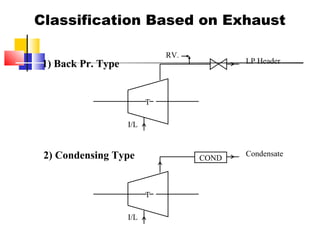

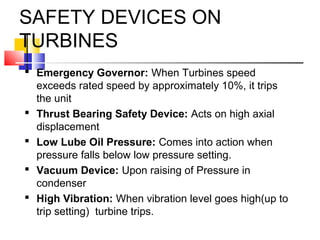

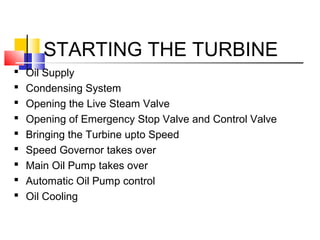

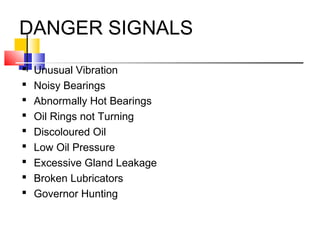

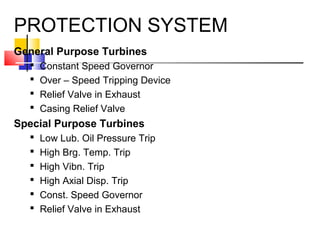

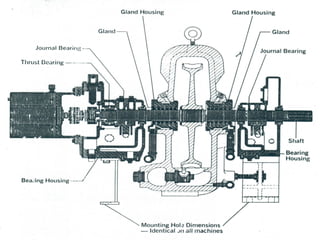

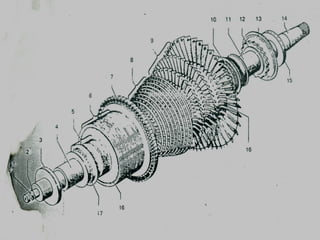

The document discusses the basics of steam turbines. It explains that steam turbines convert the potential energy of high-pressure, high-temperature steam into kinetic energy and then mechanical energy. This mechanical energy can be used to drive rotating equipment. Steam turbines are preferred in process plants because waste heat from reactions generates high-pressure steam. The document describes the main types of turbines and compares impulse and reaction turbines. It also outlines key components, safety devices, starting procedures, maintenance checks, and losses within steam turbine systems.