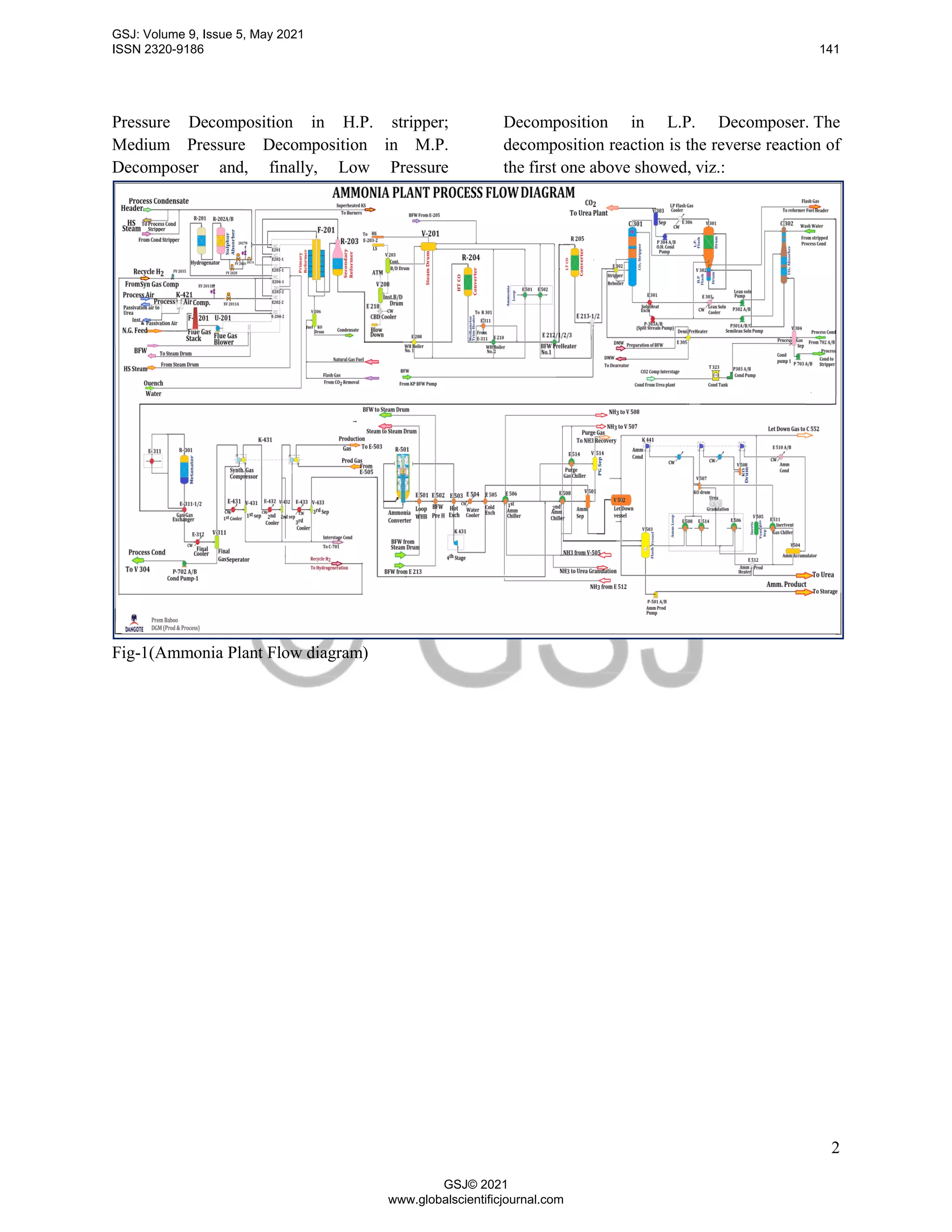

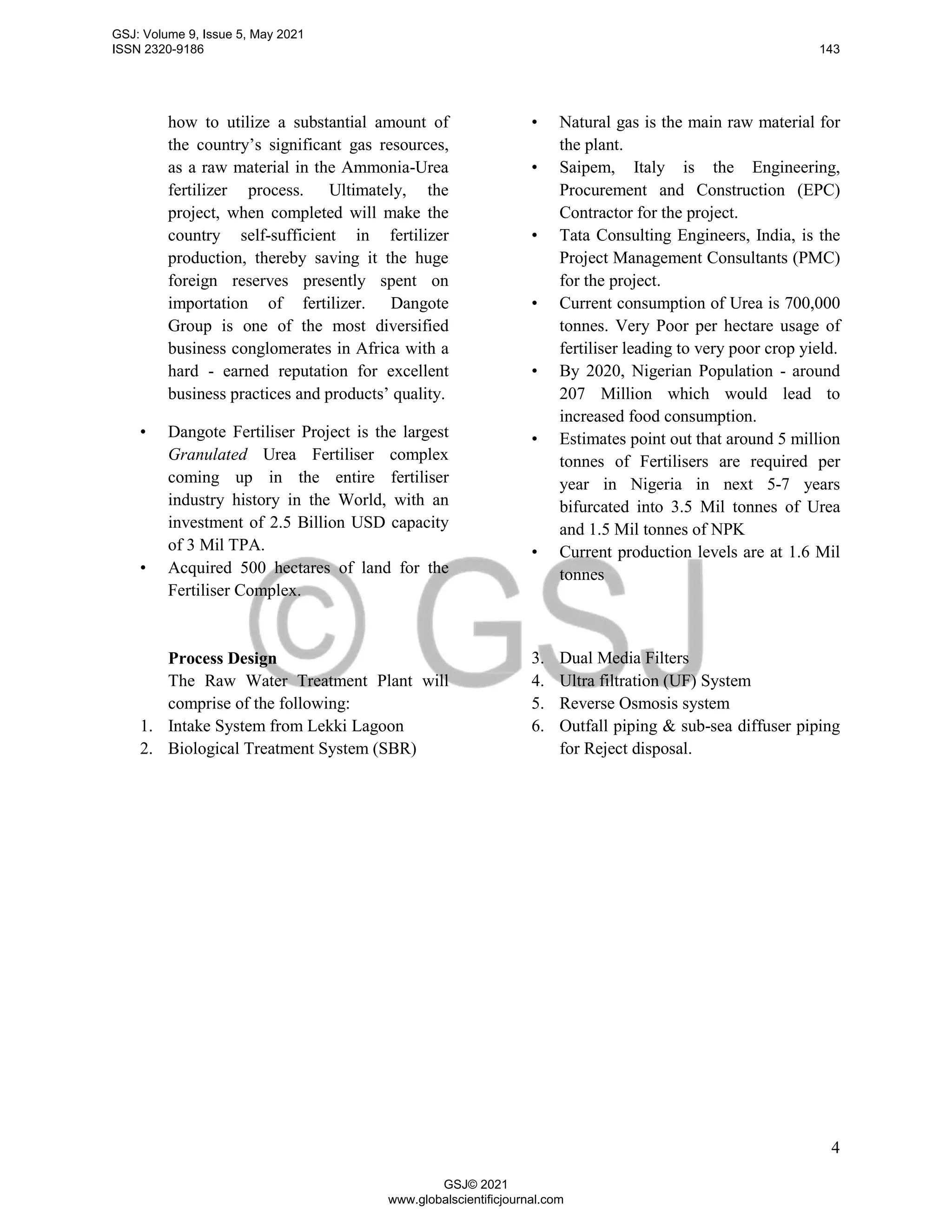

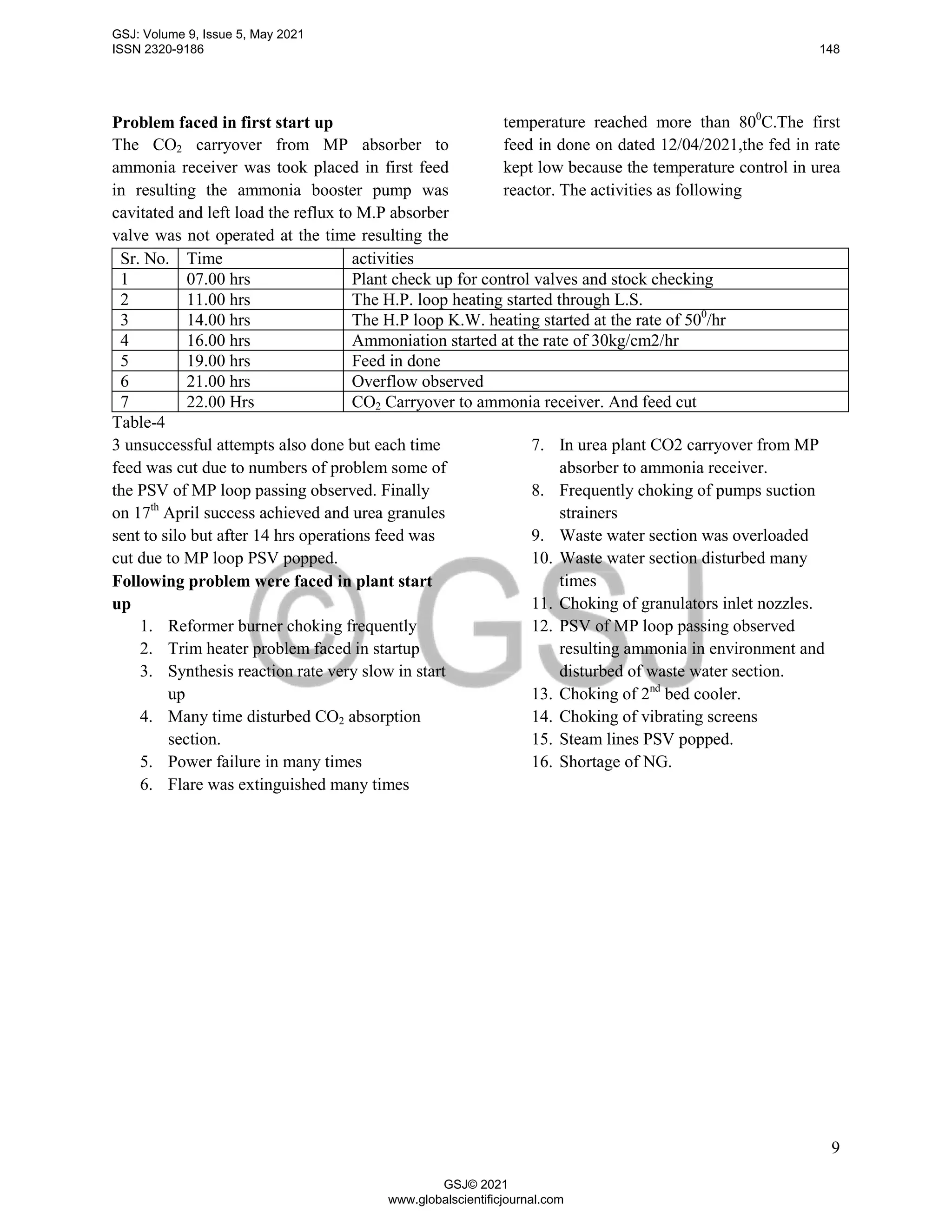

The document discusses the commissioning of the Dangote fertilizer plant, highlighting its challenges and successful startup amidst pandemic-related staffing issues. Despite multiple unsuccessful attempts, the plant achieved its first production milestone on March 17, 2021, becoming the largest single-train fertilizer facility in Africa. The paper outlines the plant's specifications, process design, and key technical achievements necessary for the production of ammonia and urea at significant scale.

![15

References-

[1] Urea Plant equipments Inspection by Prem

Baboo published in International Journal of

Engineering Research and technology

(IJERT),Volume-9 issue 03, March 2020

[2] Trouble Shooting in Water Treatment Process

for Variable TDS by Prem Baboo, Published in

International Journal of Engineering Research and

Technology(IJERT, Volume 9, Issue 04, April

2020.

GSJ: Volume 9, Issue 5, May 2021

ISSN 2320-9186 154

GSJ© 2021

www.globalscientificjournal.com

View publication stats

View publication stats](https://image.slidesharecdn.com/sweetandsourexperienceofcommissioning1-210507044841/75/Sweet-and-sour-experience-of-commissioning-1-16-2048.jpg)