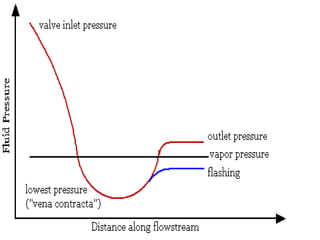

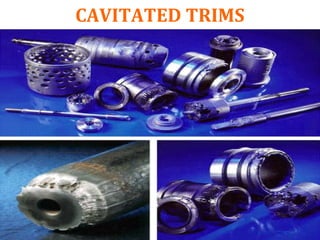

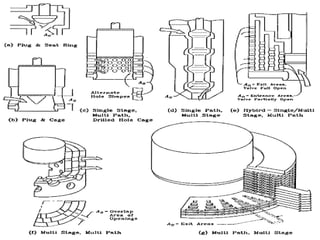

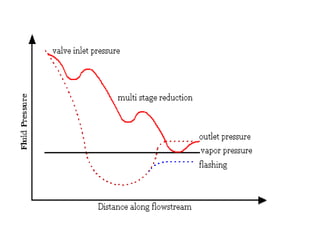

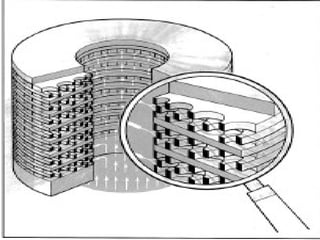

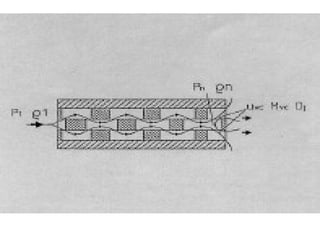

Control valves can experience several problems including cavitation, flashing, noise, and choked flow. Cavitation occurs when the pressure drops below the vapor pressure, causing vapor bubbles that implode and cause damage. Flashing happens when downstream vapor pressure is lower than upstream, causing partial vaporization. Noise stems from mechanical vibration, cavitation bubble implosions, and turbulent gas flow. Choked flow is when the flow cannot increase despite lower downstream pressure because the fluid velocity at the venturi reaches sonic speed.