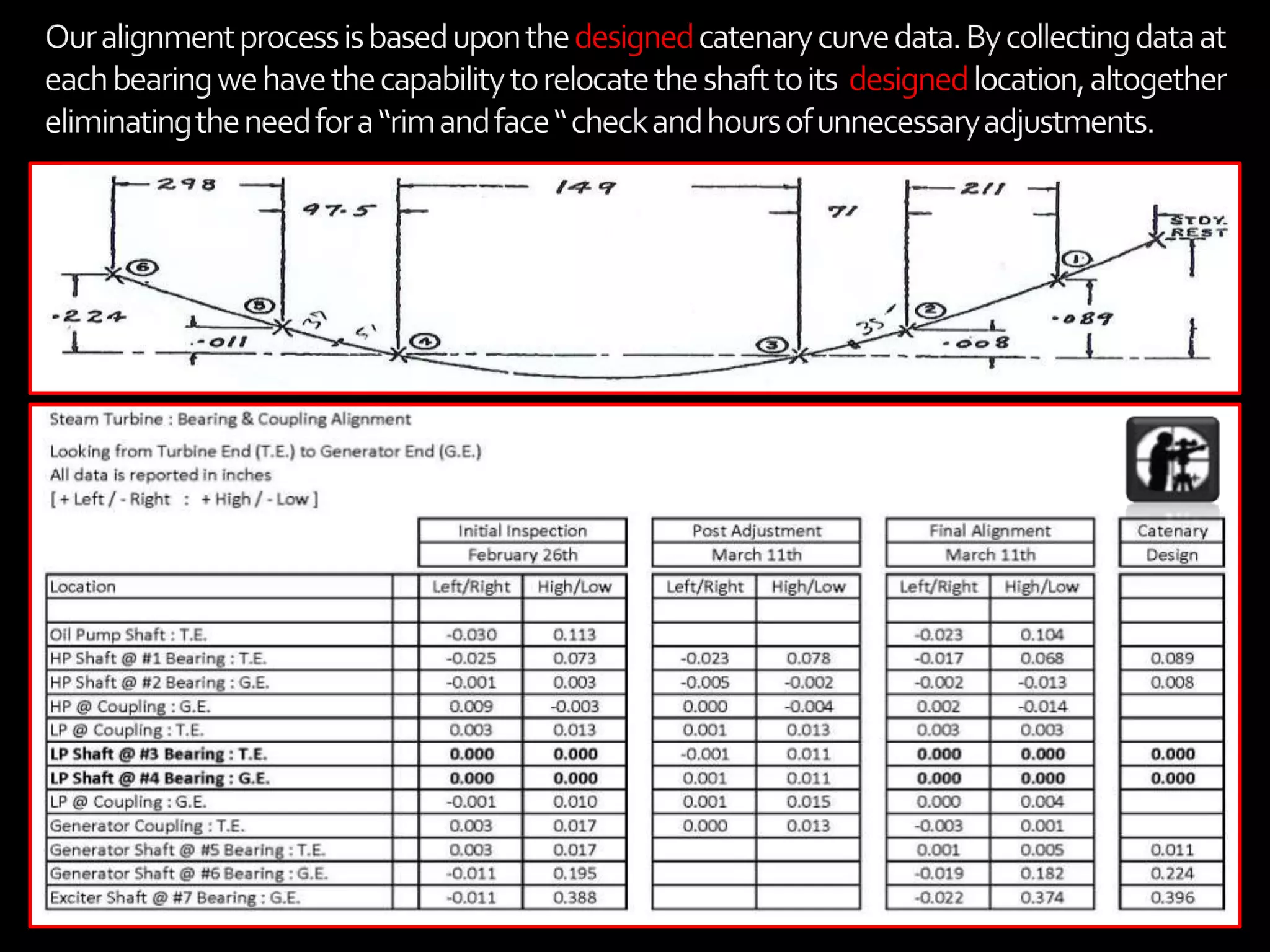

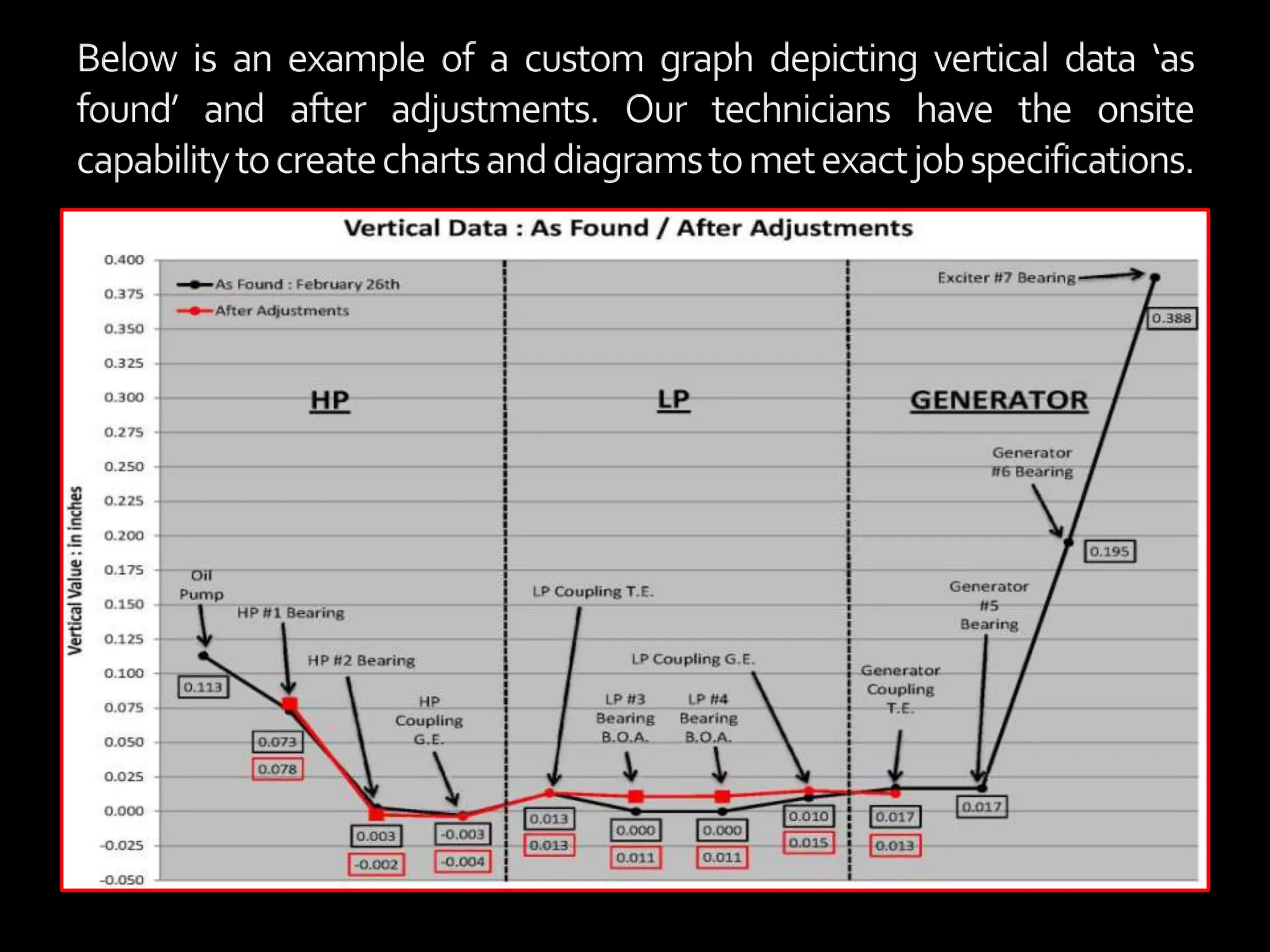

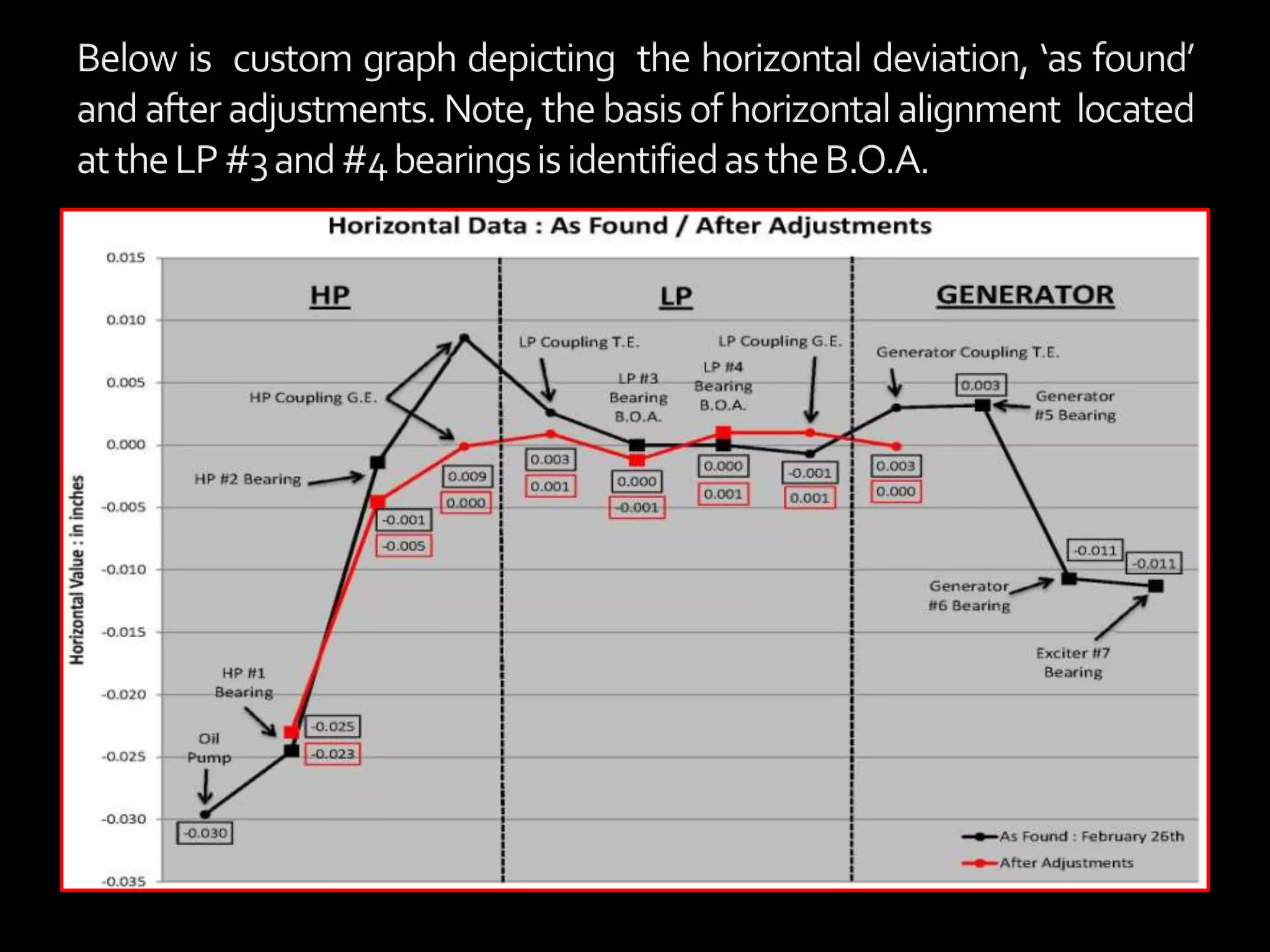

This document summarizes Schaeffer Precision Alignment's laser tracker services for inspecting steam turbines. They have experience inspecting hydro, gas, and steam turbines for over 260 clients. Their laser tracker technology allows precise inspection and alignment of individual turbine components. Inspections can locate components, monitor movement over time, and ensure reinstallation within tight tolerances. Schaeffer Precision Alignment provides a comprehensive solution for precision turbine maintenance and inspection.