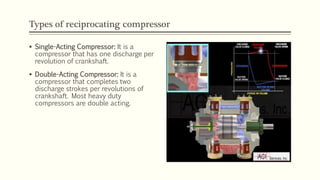

This document provides an overview of reciprocating compressors. It describes how reciprocating compressors work by using pistons moving back and forth in cylinders to compress air. The document discusses the types of reciprocating compressors, how they operate through intake and compression strokes, and diagrams to illustrate the compression process. It also covers startup procedures, safety concerns around carbon buildup and explosions, efficiency calculations, and specifications for a sample reciprocating compressor.