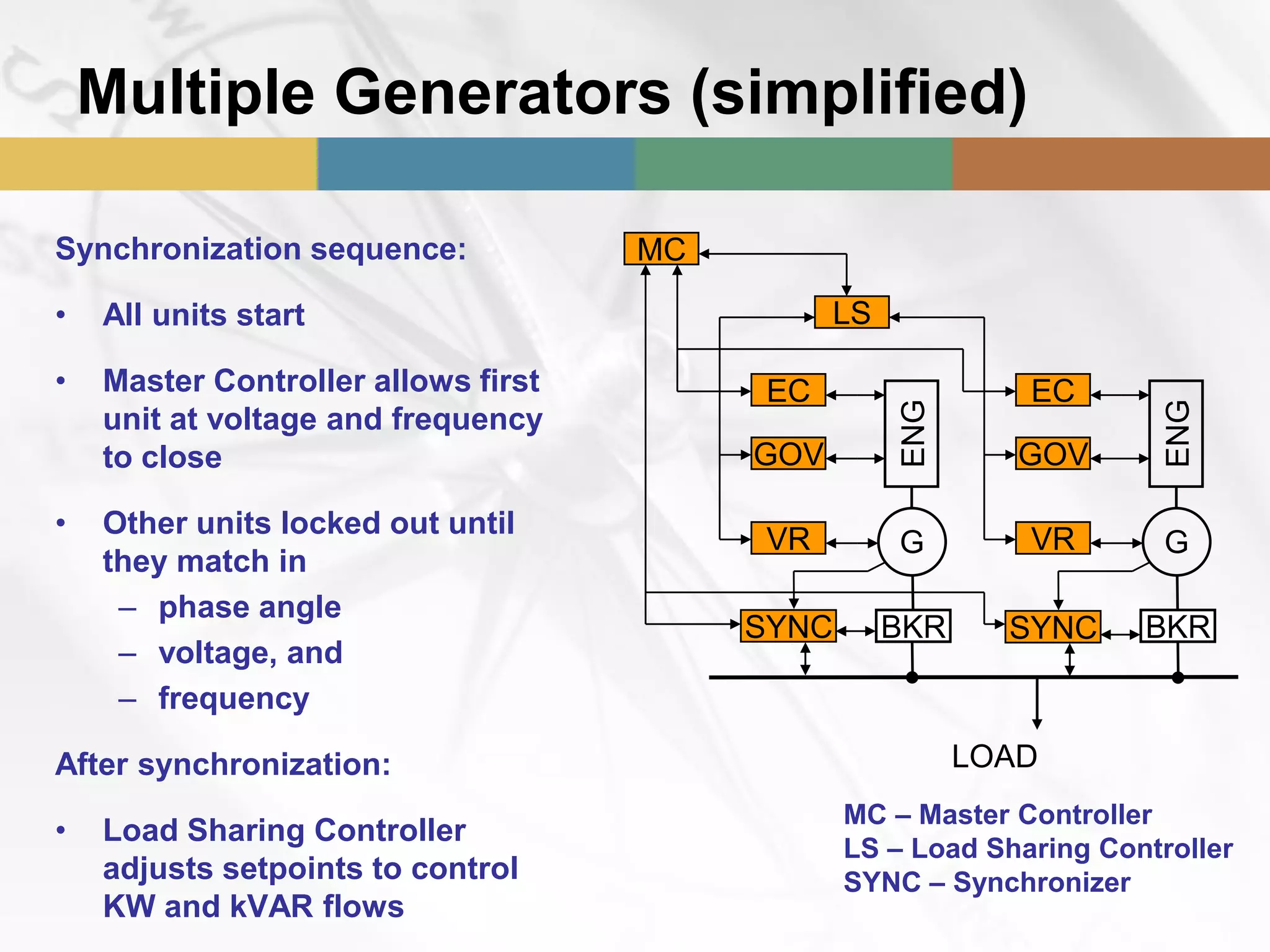

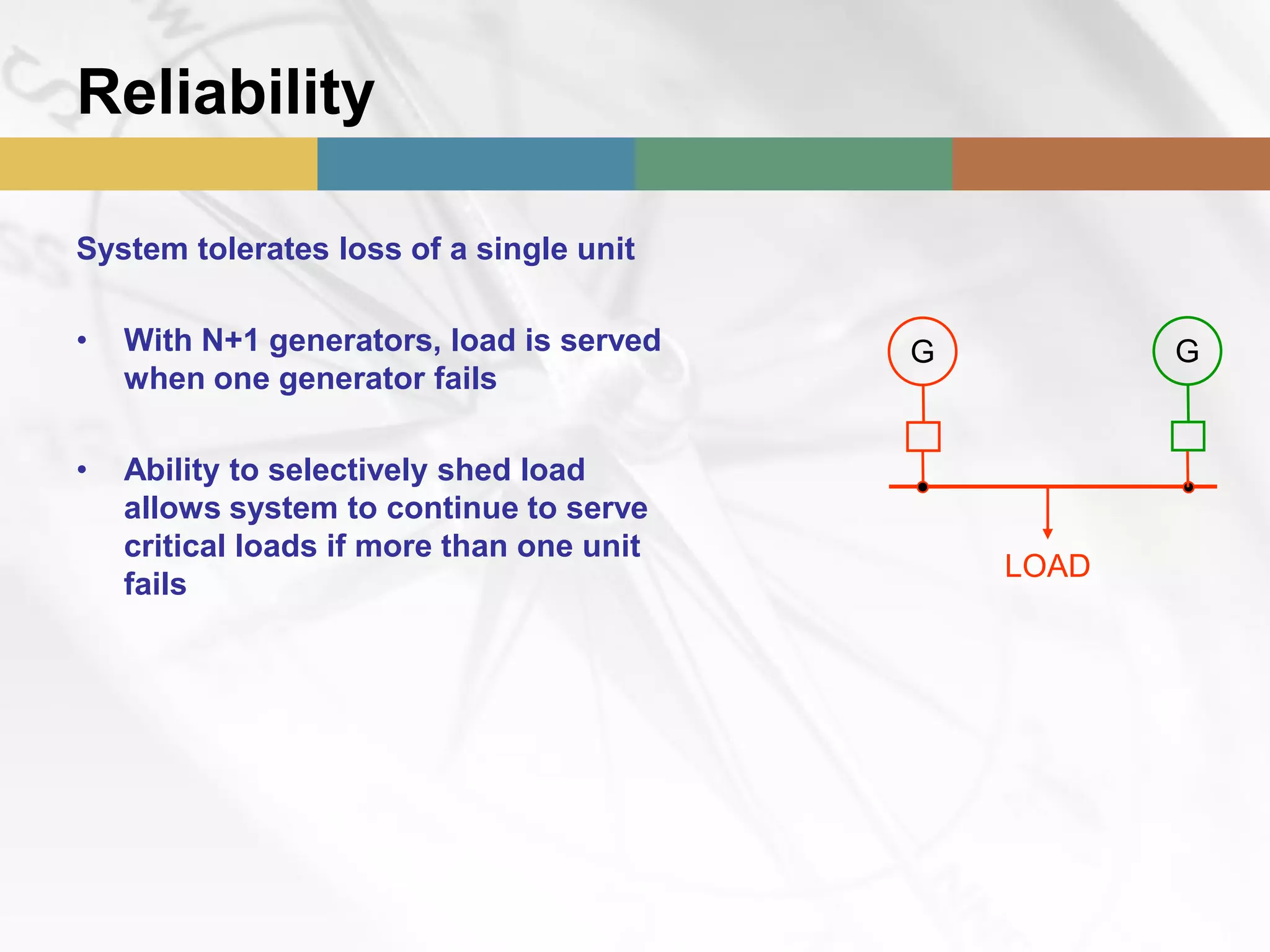

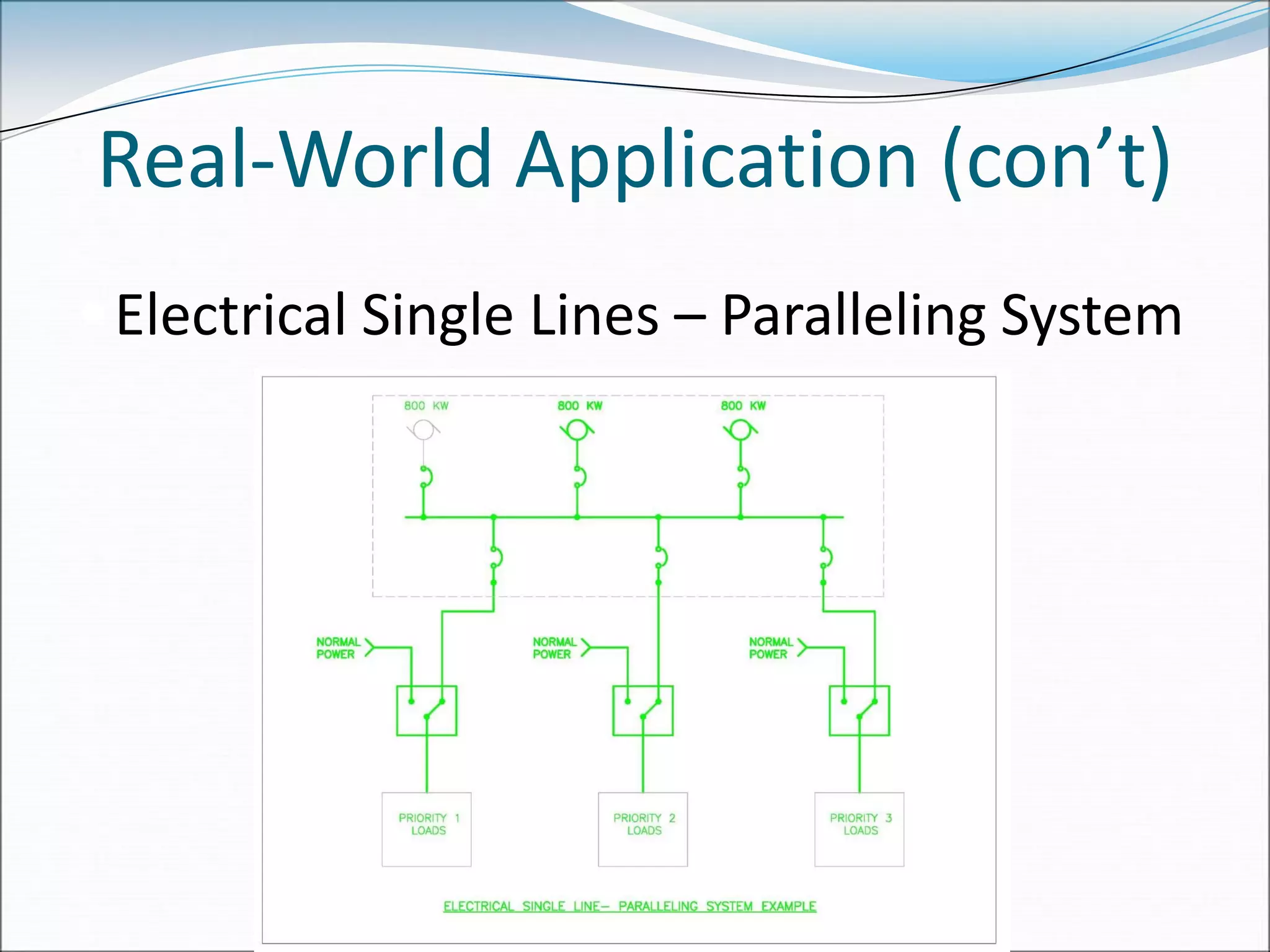

This document discusses the debate around whether paralleling generators is a good idea for hospital standby power systems. It provides an overview of how generator paralleling works, including the requirements and components needed. The advantages of paralleling include increased reliability if one generator fails, more flexibility, and better overall system performance compared to a single generator. While paralleling equipment adds some costs, proponents argue the reliability benefits are worth it. However, some argue hospitals could save money by not using paralleling and instead implementing load shedding of lower priority equipment in an outage. The document examines both perspectives on this issue.