This document provides an overview of motor acceleration studies, including:

- The purpose of motor acceleration studies is to ensure motors can start under voltage drops and are adequately sized.

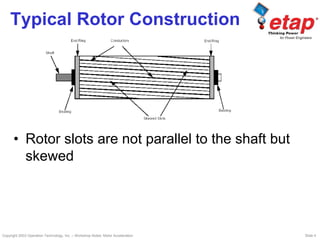

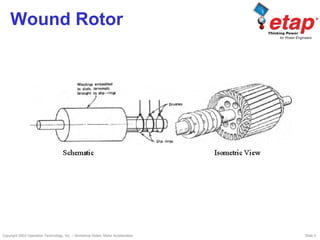

- Common motor types include synchronous, induction, and wound rotor motors.

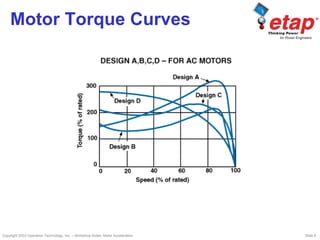

- Motor acceleration is modeled either statically using locked rotor impedance or dynamically using characteristic curves.

- Starting devices like auto-transformers, resistors, and reactors can be modeled to study their effect on motor starting.

![Copyright 2003 Operation Technology, Inc. – Workshop Notes: Motor Acceleration Slide 21

Circuit Model II

• Single Cage Rotor

– “Single2” - deep bar effect, rotor resistance and

reactance vary with speed [Xm is removed]](https://image.slidesharecdn.com/09-motor-acceleration-170511153531/85/ETAP-09-motor-acceleration-21-320.jpg)