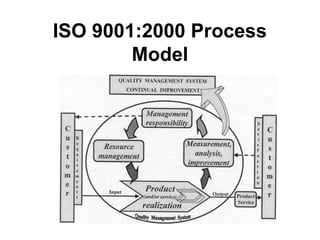

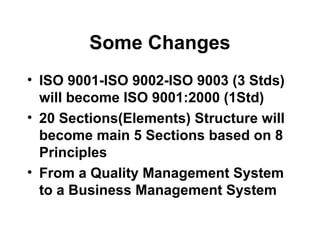

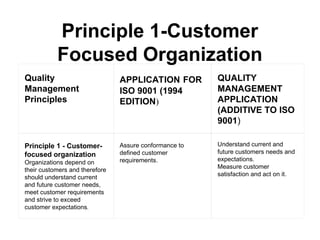

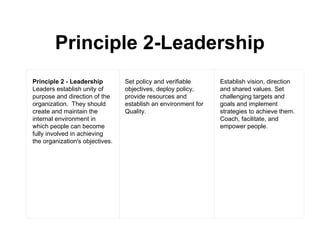

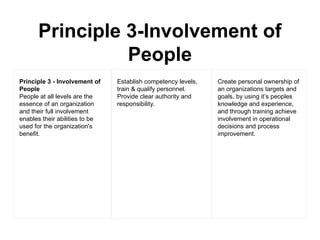

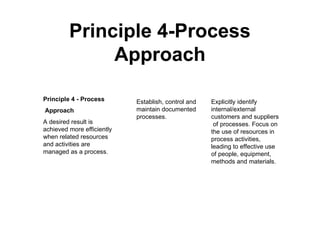

ISO, derived from the Greek word 'isos' meaning 'equal', is a voluntary organization that creates international standards and is supported by national standard authorities from member countries. Founded to enhance product quality, safety, and compatibility, ISO standards facilitate global trade and improve organizational efficiency. The ISO 9000 series, including ISO 9001, outlines quality management frameworks to ensure consistent product and service quality across various sectors.