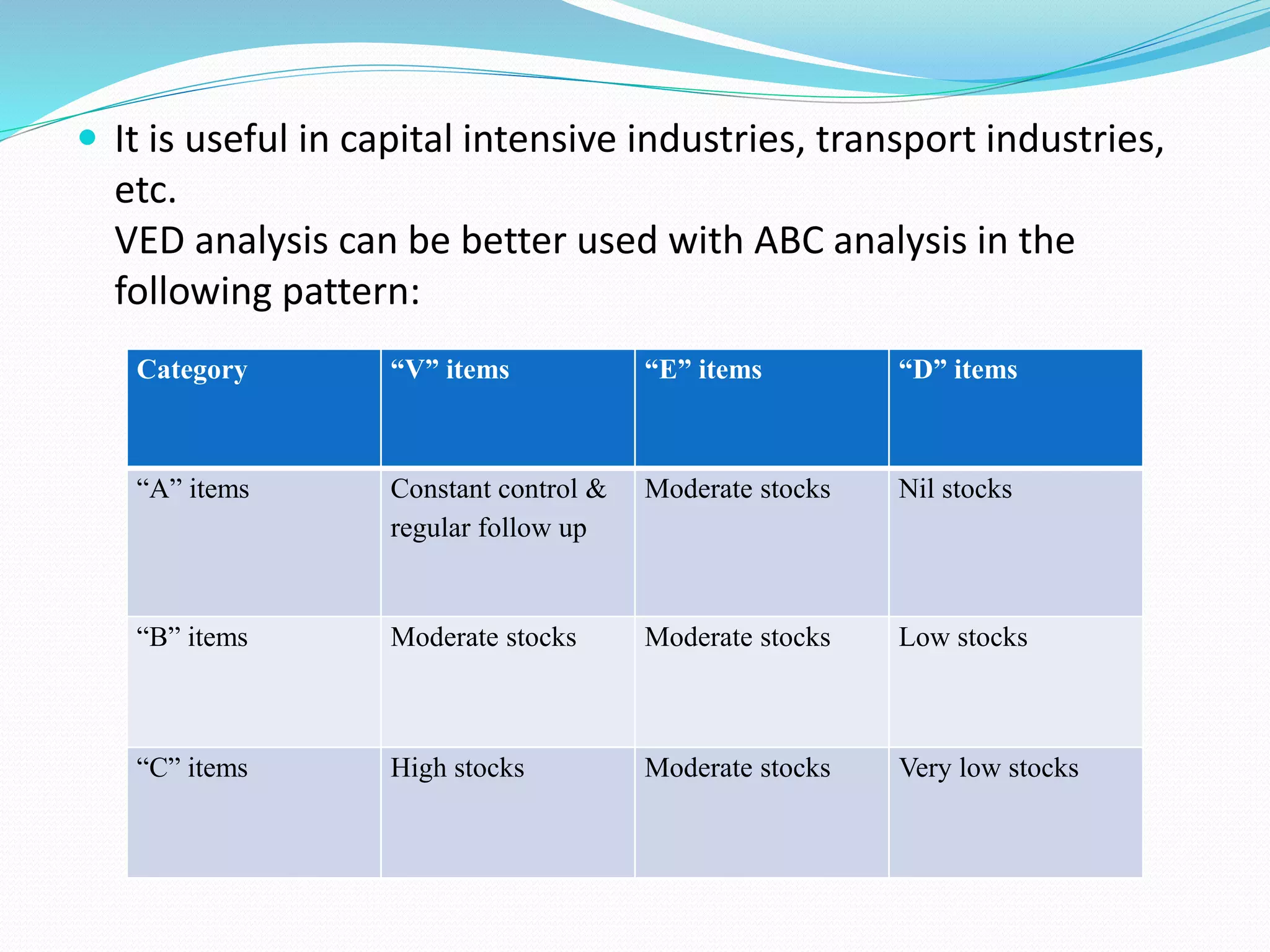

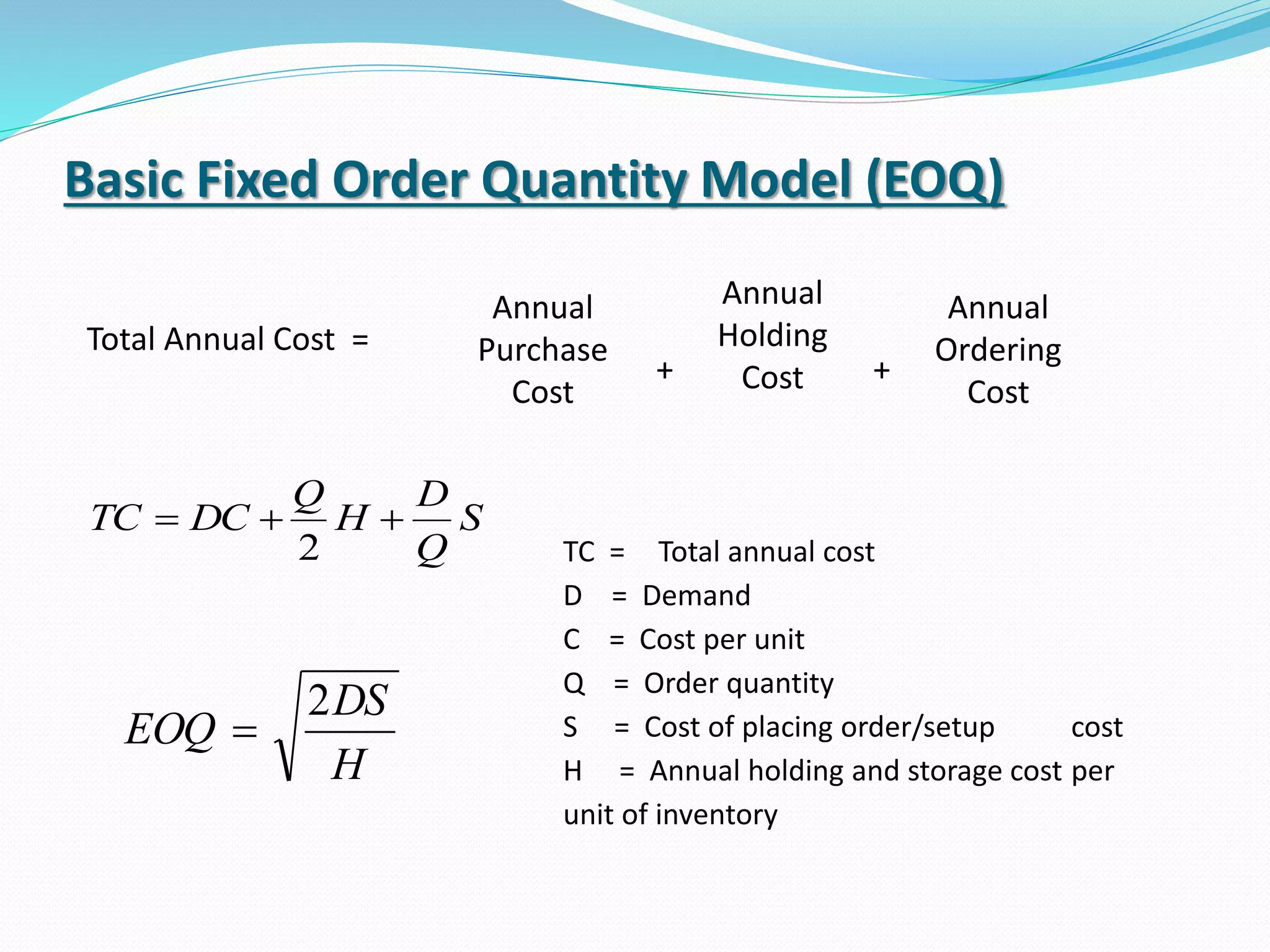

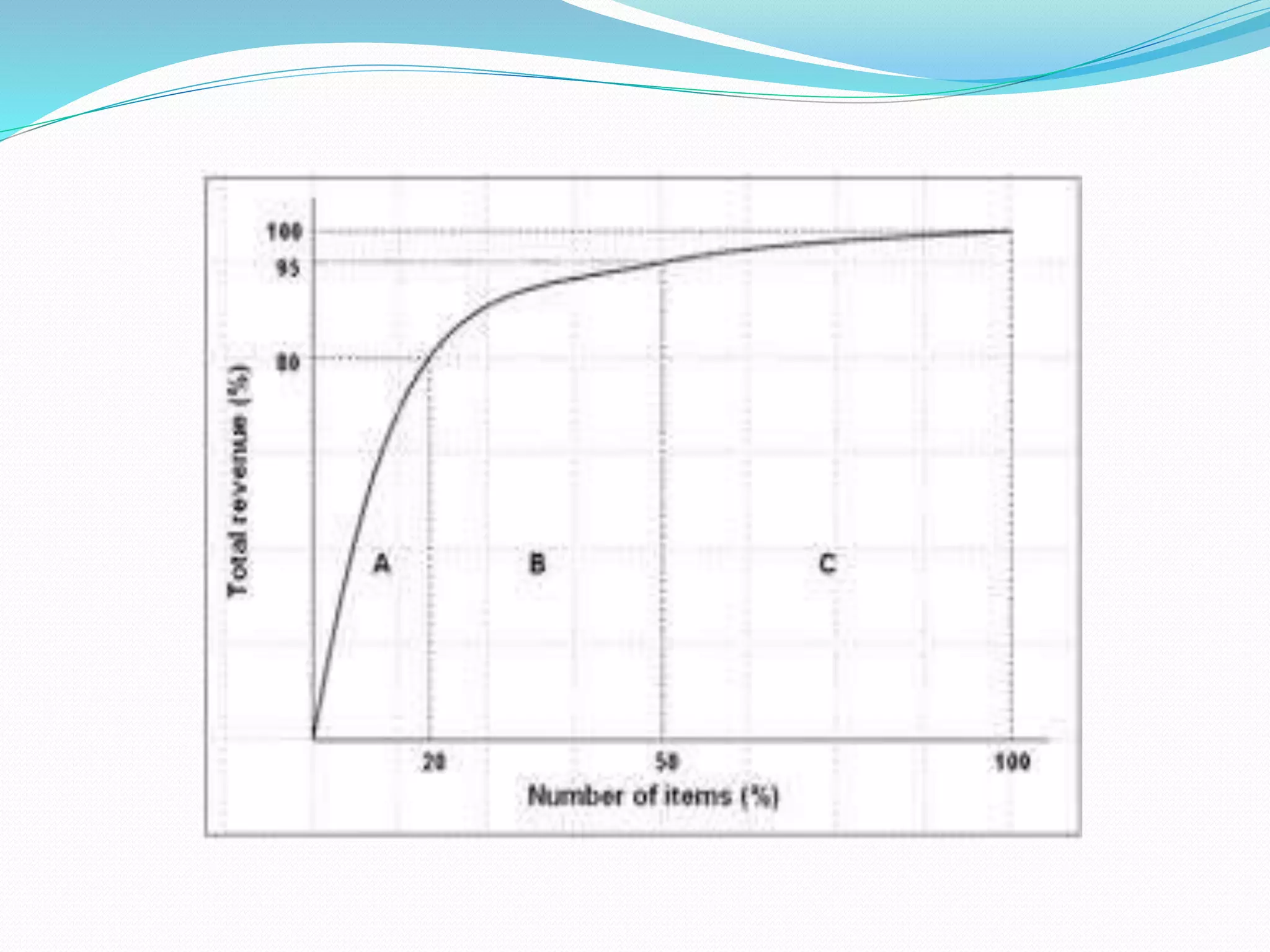

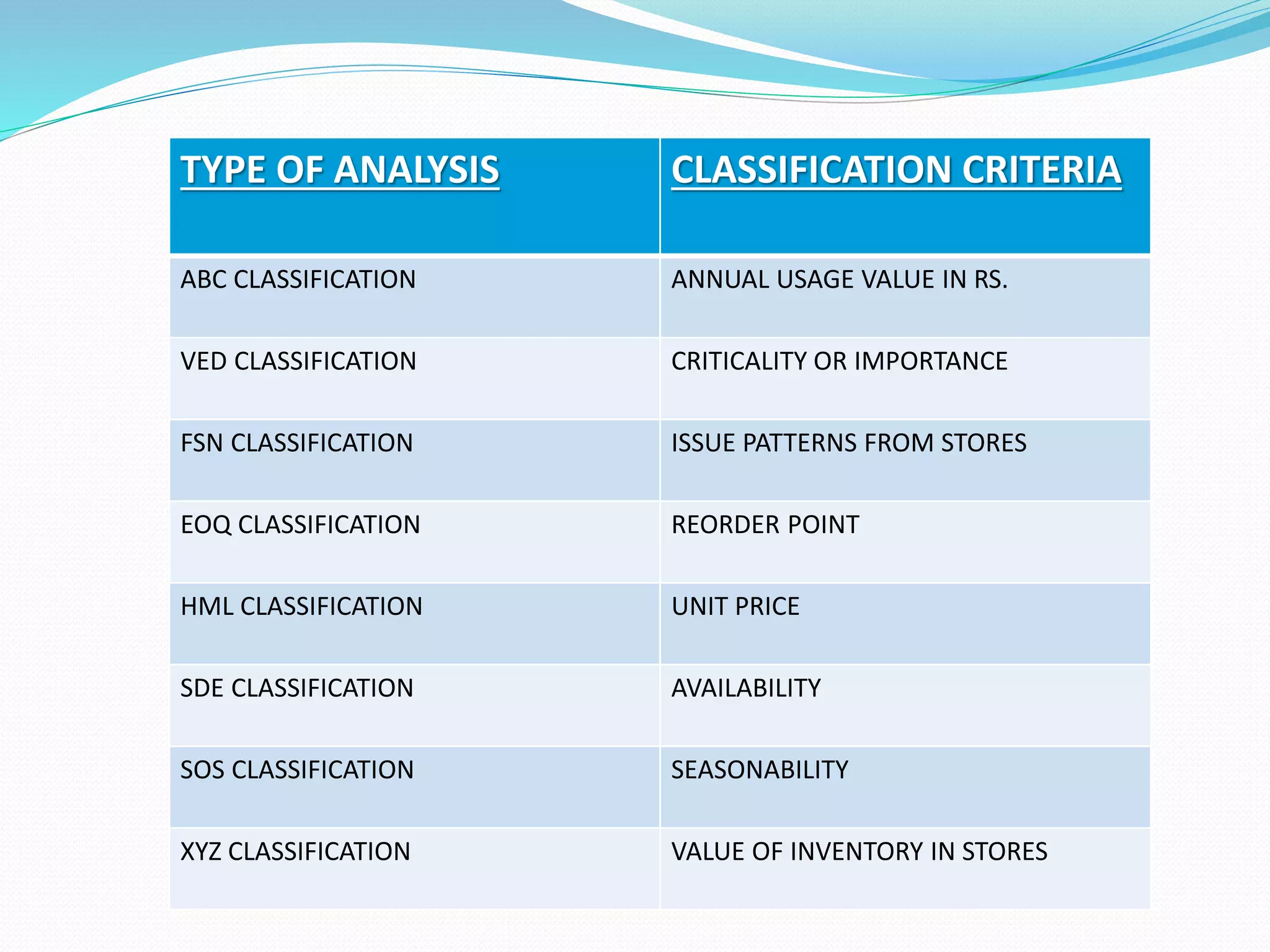

This document discusses inventory management, defining it as the management of raw materials, work-in-process, and finished goods. It outlines various inventory control techniques such as ABC, VED, FSN, and EOQ classifications, each serving different purposes based on consumption value, criticality, and movement patterns. Additionally, it provides insights into the significance of these techniques for optimizing inventory levels and ensuring efficient organizational operations.