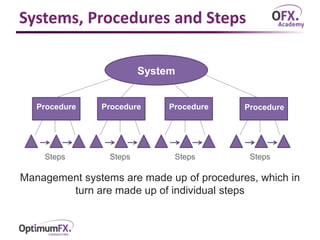

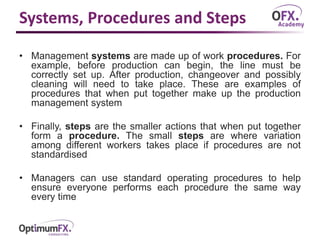

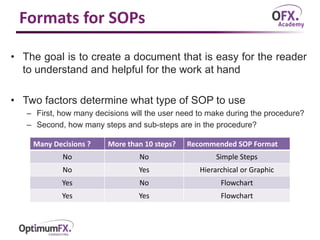

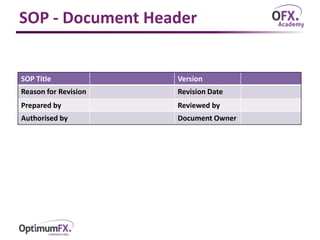

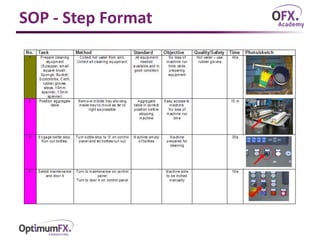

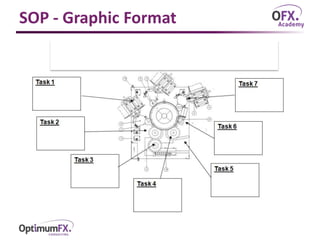

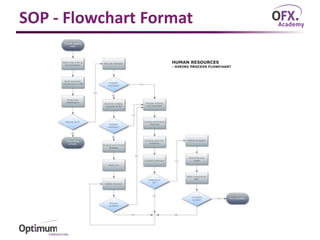

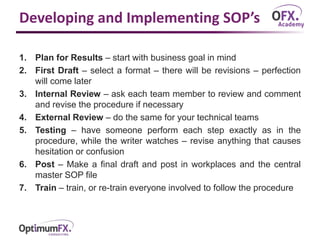

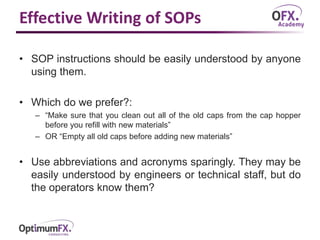

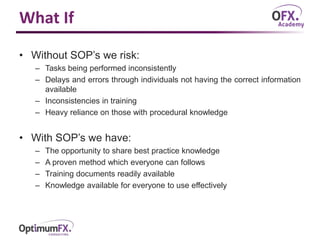

The document outlines the importance of Standard Operating Procedures (SOPs) in ensuring consistent and accurate work performance in businesses. SOPs serve as detailed manuals for tasks, helping to standardize processes and improve communication and training. It emphasizes the need for well-written and regularly updated SOPs to meet regulatory standards and facilitate employee training and efficiency.