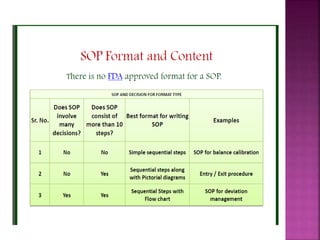

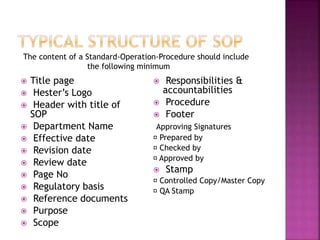

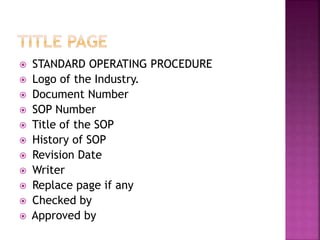

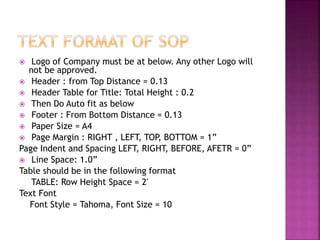

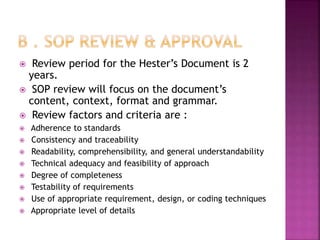

The document discusses standard operating procedures (SOPs) and quality systems. It provides definitions and guidelines for developing effective SOPs, including describing their purpose, required contents, formats, types of documents, and procedures for review and revision. It emphasizes that SOPs should be written clearly and provide step-by-step instructions to ensure processes are followed consistently and comply with regulations. Training users and obtaining feedback on SOPs is also highlighted as important for proper implementation.

![ GOOD MANUFACTURING PRACTICES AND

REQUIREMENTS OF PREMISES, PLANT AND

EQUIPMENT FOR PHARMACEUTICAL PRODUCTS.

Note: - To achieve the objectives listed below,

each licensee shall evolve appropriate

methodology, systems and procedures which

shall be documented and maintained for

inspection and reference; and the manufacturing

premises shall be used exclusively for production

of drugs and no other manufacturing activity

shall be undertaken therein.

[SCHEDULE M]](https://image.slidesharecdn.com/standardoperatingproceduresopassignment-200426155550/85/Standard-operating-procedure-sop-assignment-6-320.jpg)