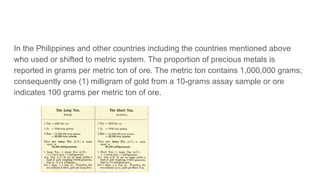

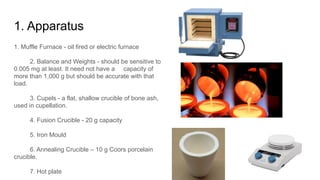

Fire assaying is a method of determining the proportion of precious metals like gold and silver in ores. It involves melting samples with fluxes at high temperatures. The metals dissolve in molten lead and are separated from slag. Lead is removed by oxidation, leaving a gold-silver alloy called dore. Acid treatment separates silver from gold. Fire assaying provides an economical way to analyze large samples and is still widely used today due to its accuracy and simplicity despite the development of modern analytical techniques.