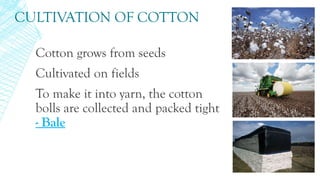

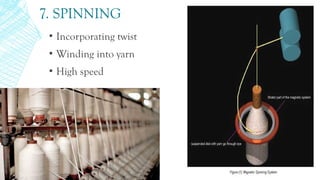

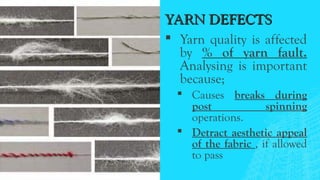

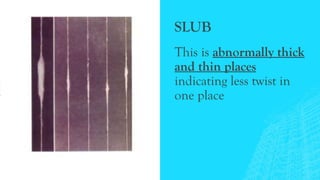

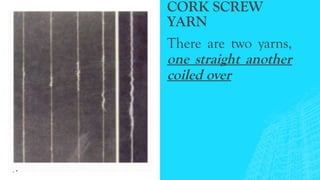

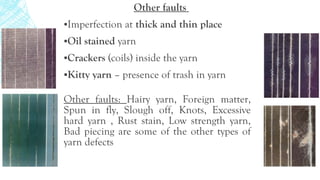

The document discusses the processes of spinning yarn from cotton, including ginning, carding, and roving, and highlights common yarn defects that can affect fabric quality. It also elaborates on the properties and specifications of sewing threads, their application in various industries, and the importance of quality in maintaining seam integrity and production efficiency. Key attributes of good sewing thread include uniformity, color fastness, and resistance to chemicals and abrasion.