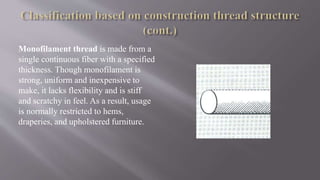

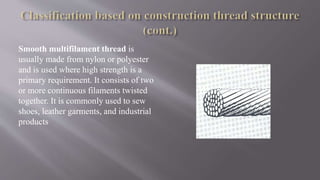

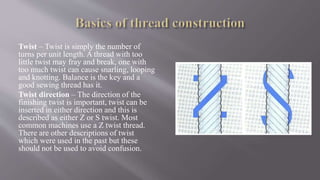

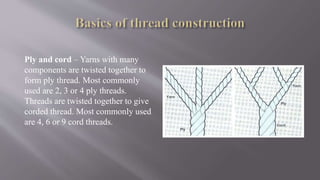

The document discusses the importance of thoroughly understanding sewing thread. It covers various factors that affect the aesthetics and performance of threads, such as color, luster, thickness, seam strength, and abrasion resistance. Additionally, it describes different types of threads based on their substrate, construction, and finish to achieve properties like high strength, smoothness, and durability. Proper thread selection and an understanding of thread parameters are essential for achieving good sewing performance and seam quality.