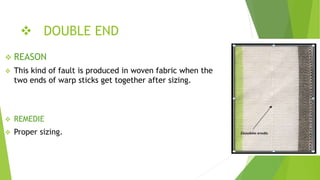

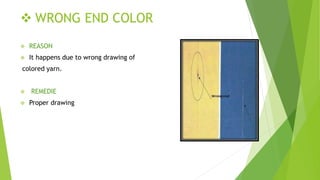

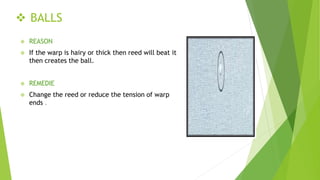

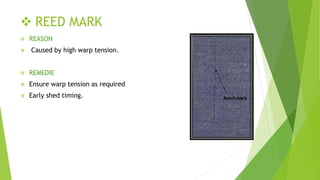

This document summarizes common defects that can occur during the weaving process and their causes and remedies. It identifies defects such as double ends, wrong end color, slubs, broken ends, double picks, balls, holes, oil spots, reed marks, foreign materials, and thick and thin places. Each defect is explained along with how it can occur and recommendations for preventing or fixing the issue, such as ensuring proper sizing, drawing, spinning, tension control and cleaning of yarns. The goal is to identify defects early to maintain fabric quality and the aesthetic appeal of final garments.