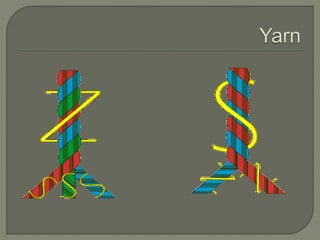

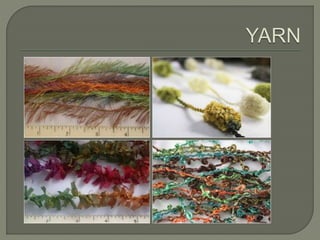

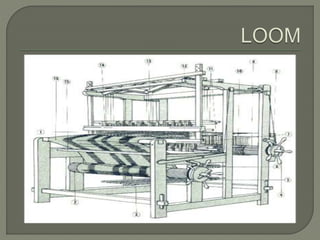

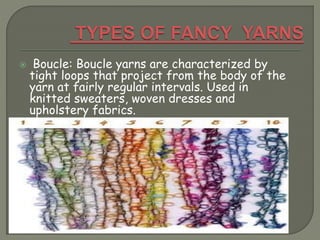

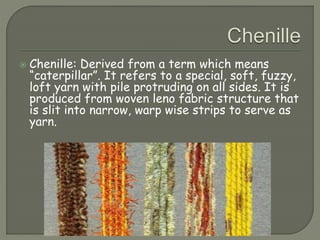

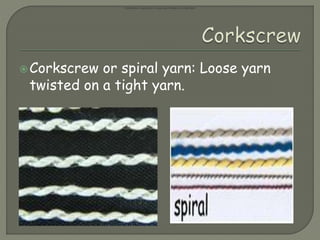

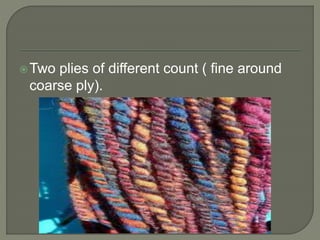

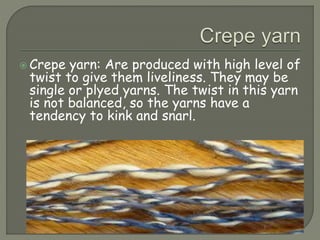

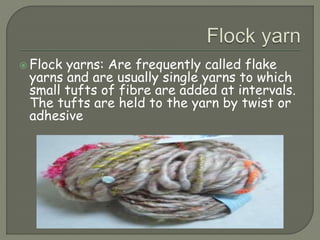

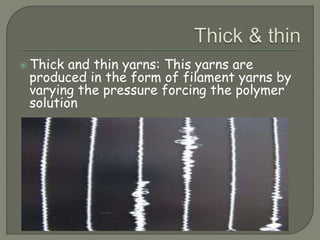

The document discusses different types of yarns used in textiles, including their construction and properties. It describes simple yarns made of twisted fibers, ply yarns made by twisting multiple simple yarns together, and cabled yarns made by twisting ply yarns with opposite twist directions. The amount of twist impacts yarn strength and fabric hand. Specialty yarns are also discussed, such as novelty yarns that create texture, as well as boucle, chenille, corkscrew, crepe, flock, and slub yarns. Weaving, knitting and other fabric construction methods are briefly introduced.