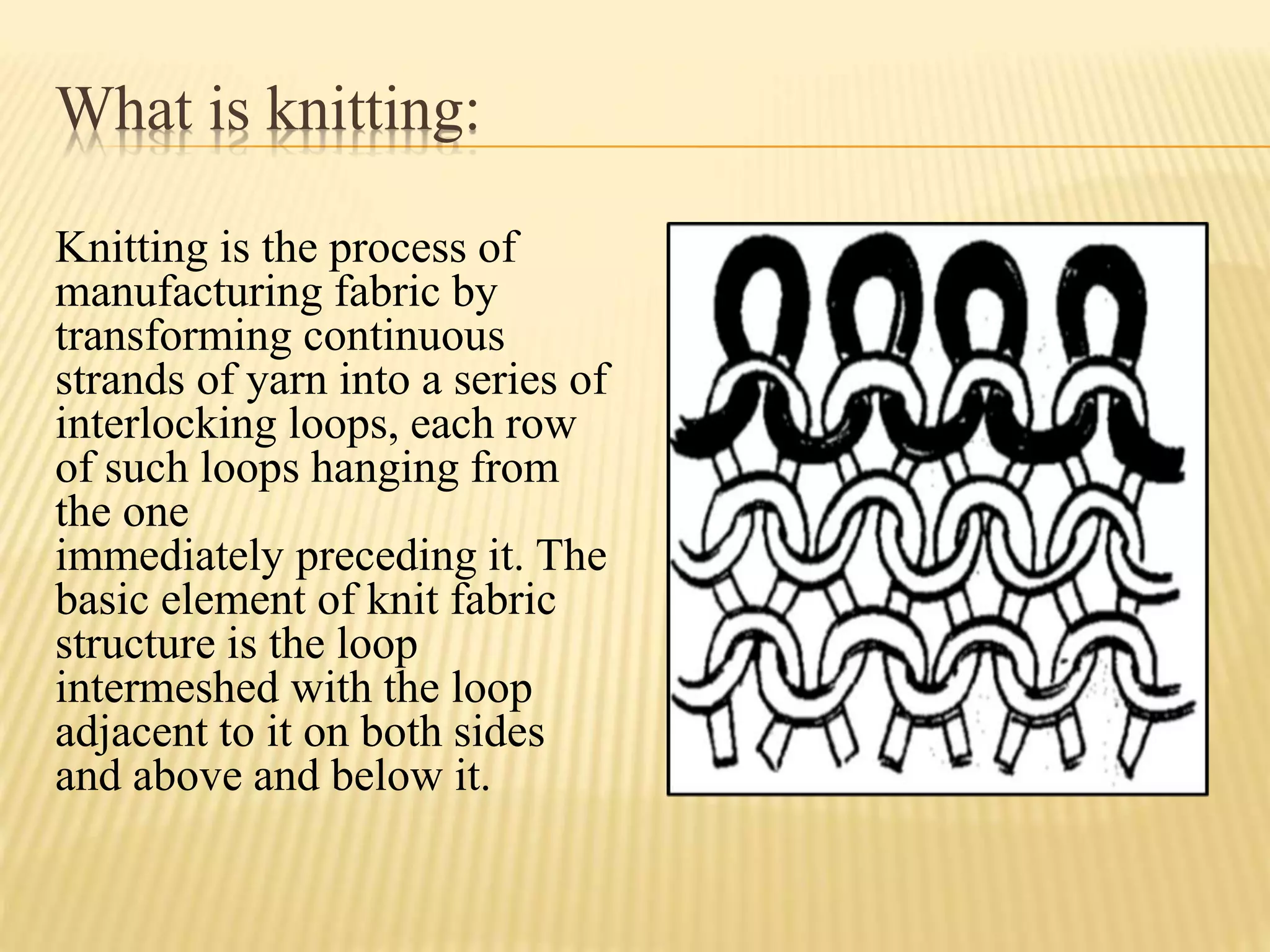

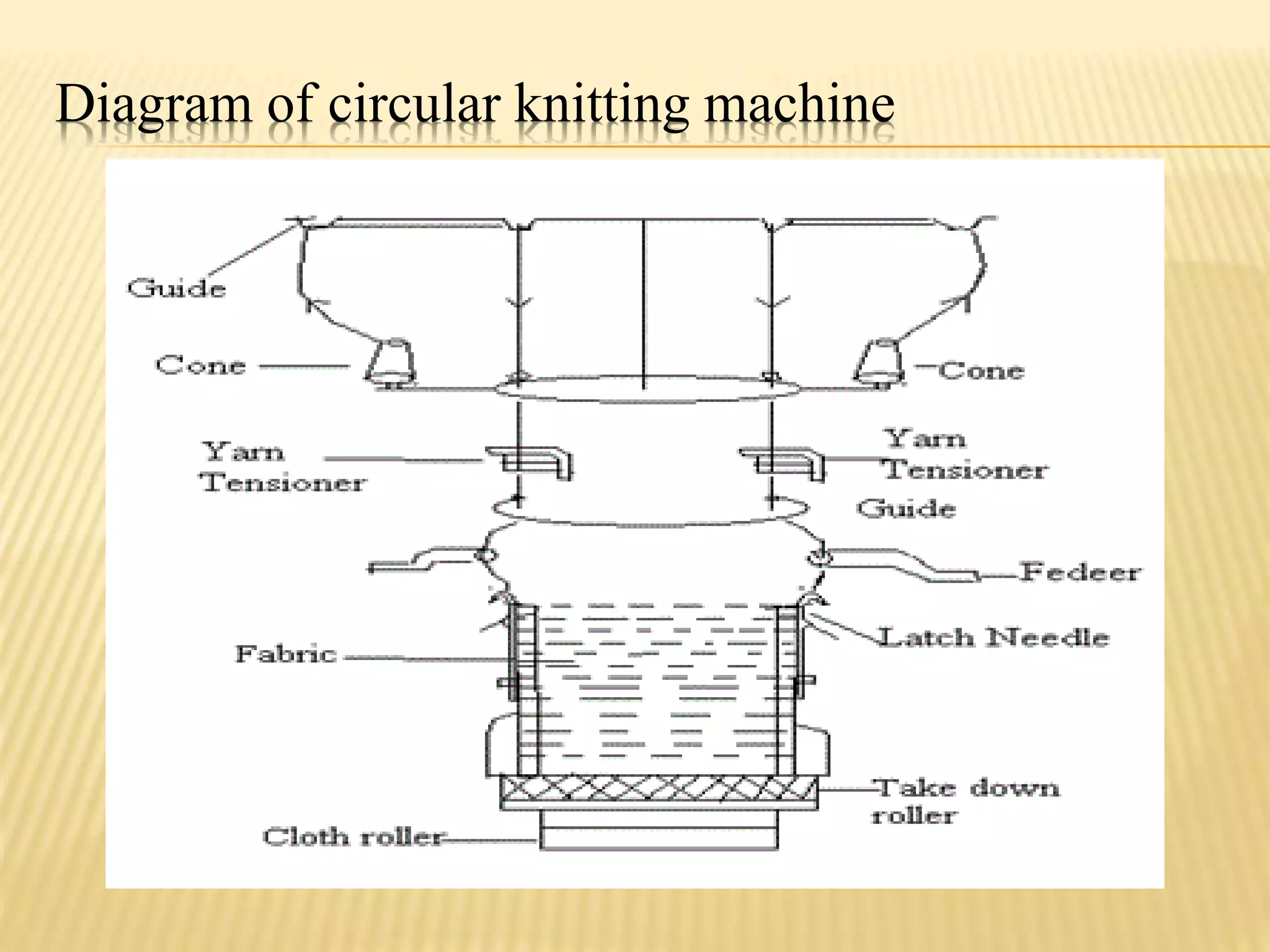

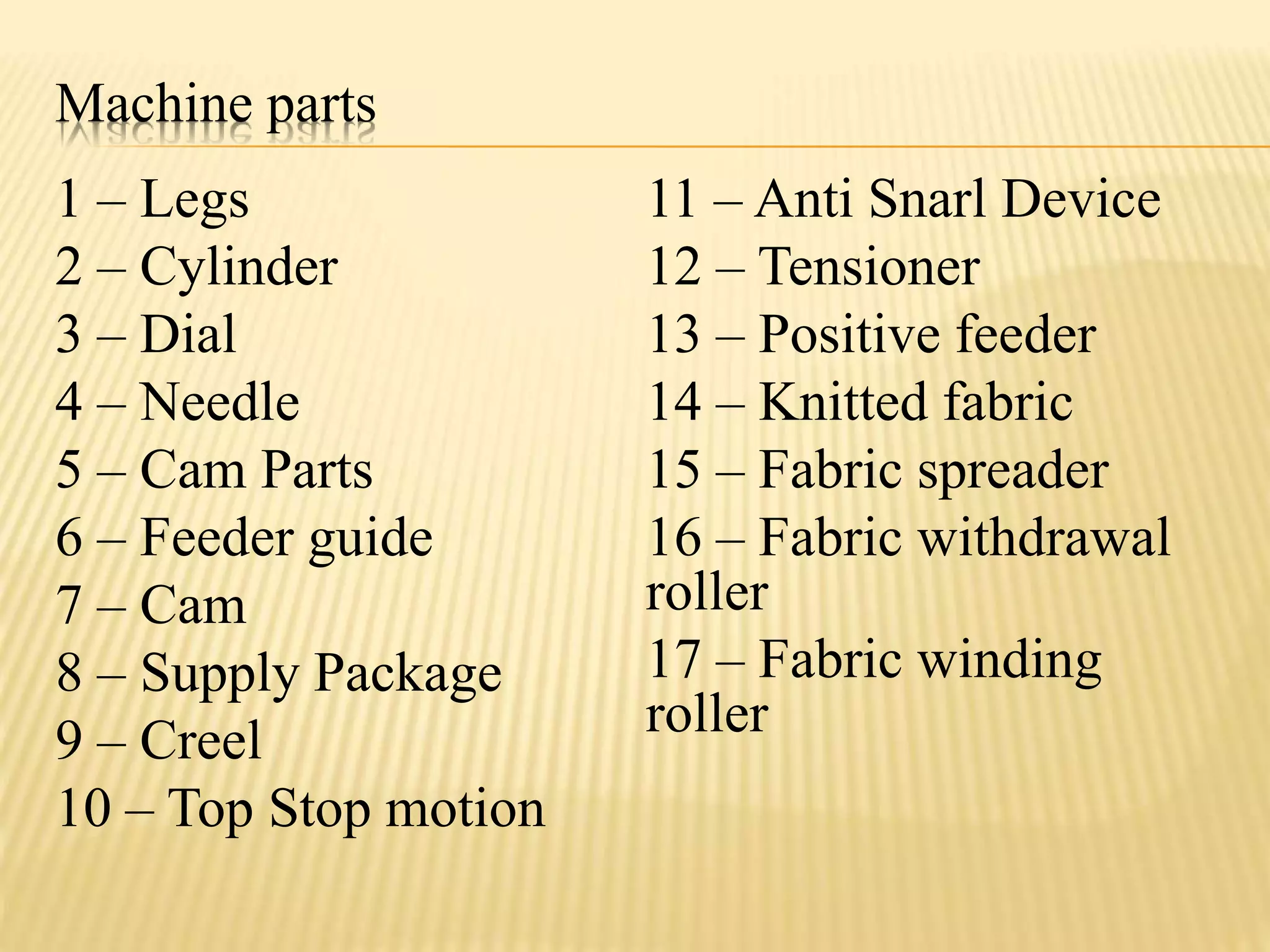

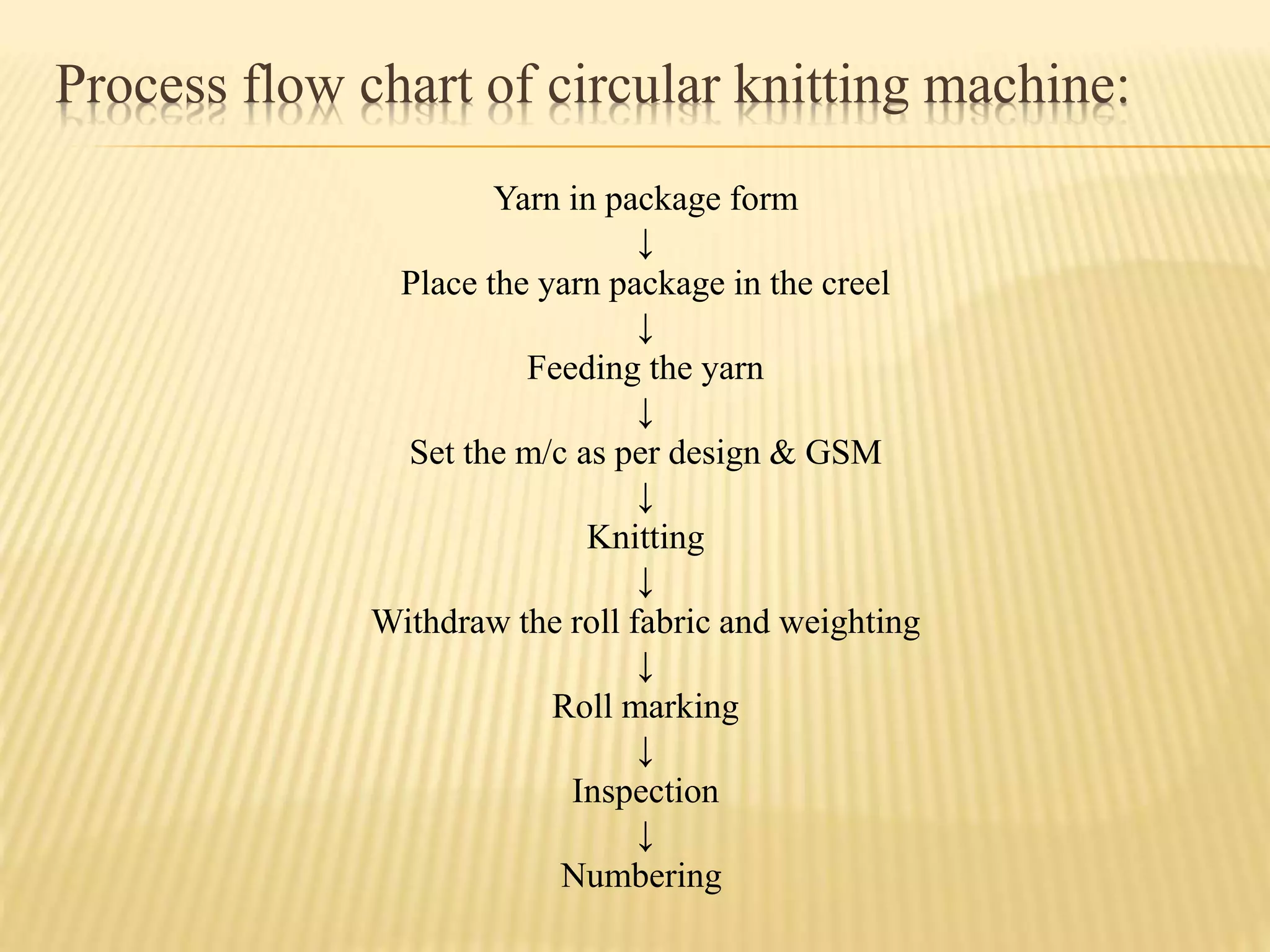

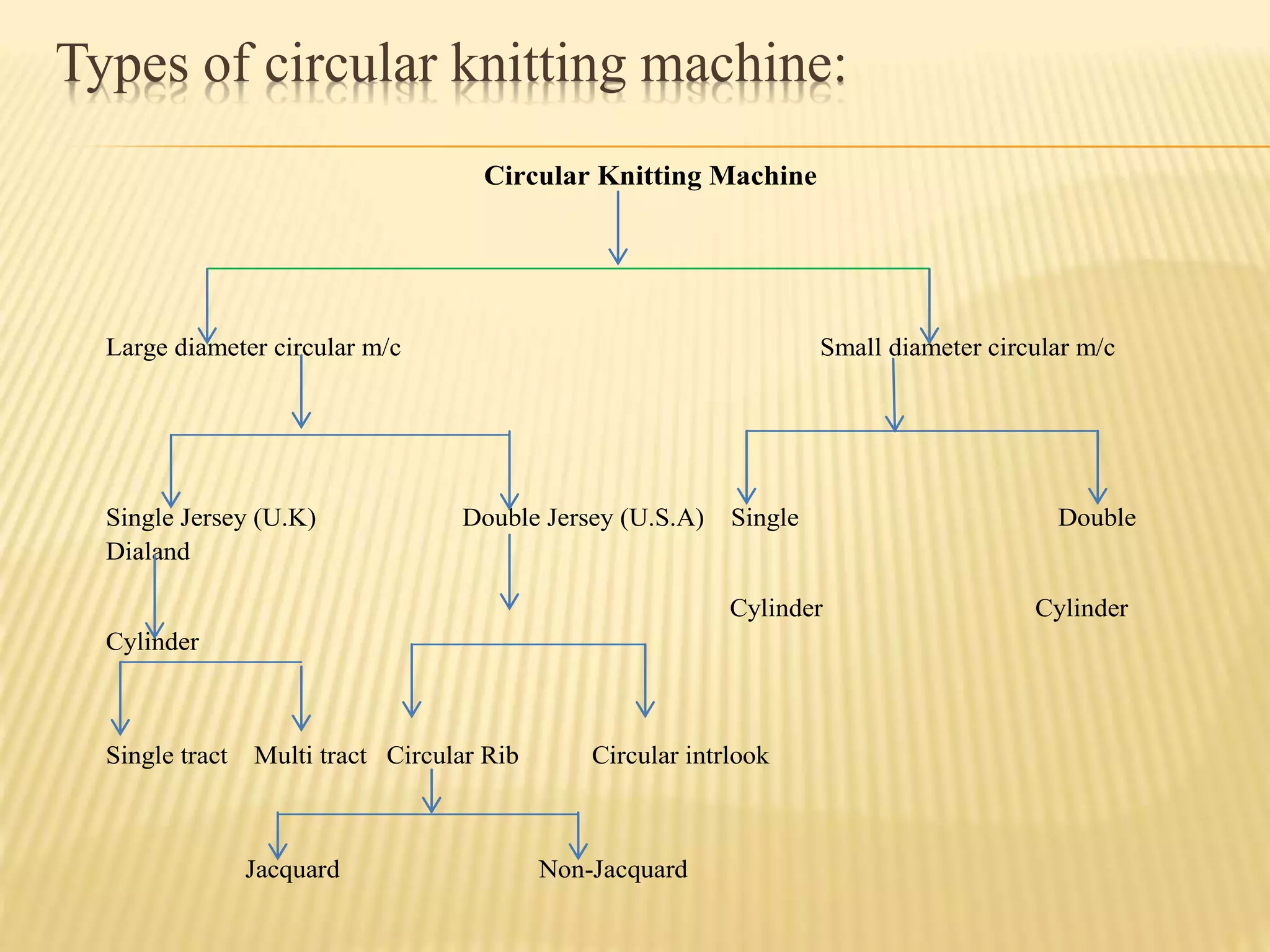

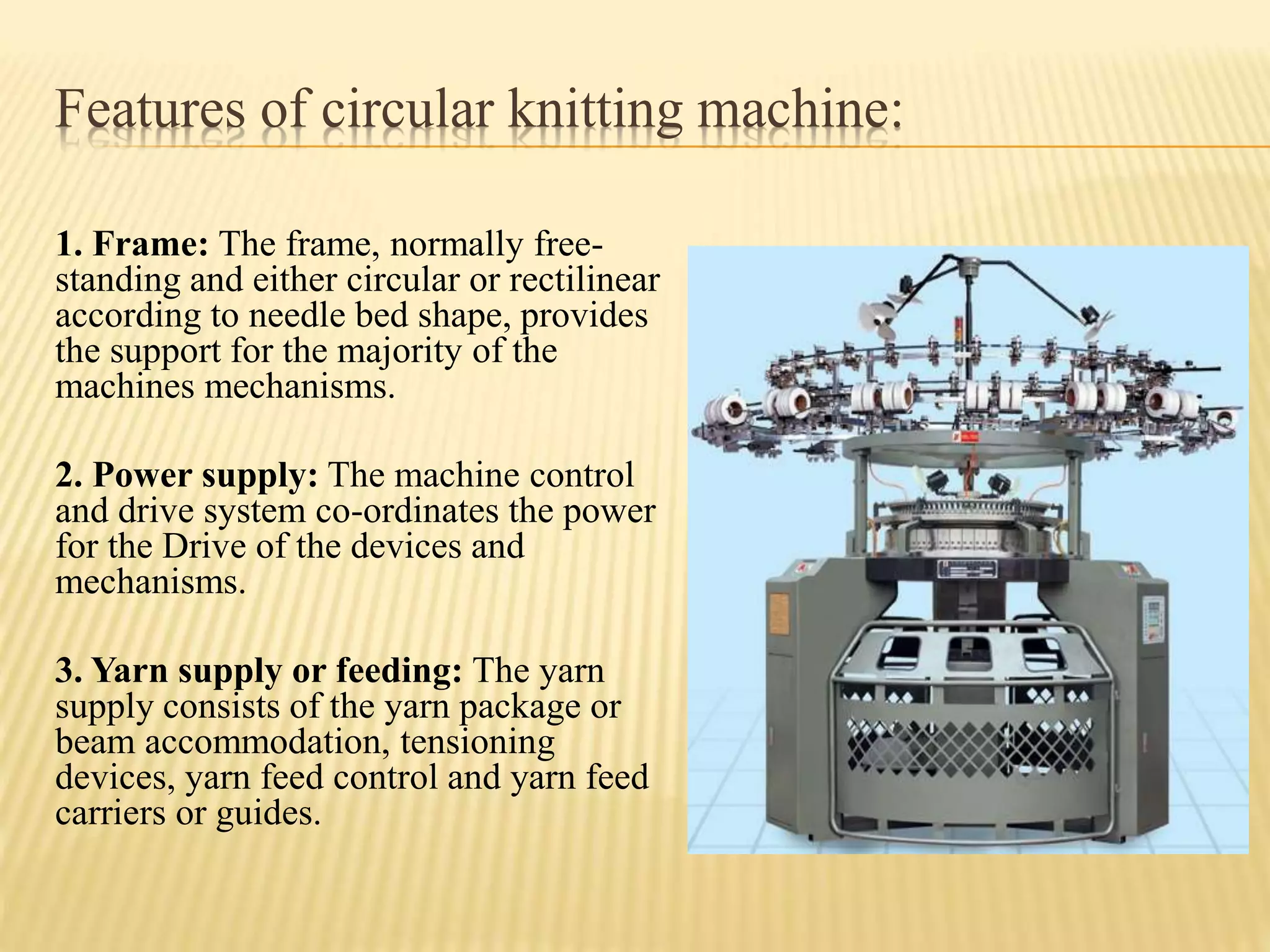

The document provides information about circular knitting machines. It defines knitting as transforming yarn into interlocking loops. Circular knitting creates seamless tubes using circular needles or machines. Machine parts include the frame, power supply, yarn feeding system, and quality control components. Circular knitting machines are used to produce fabrics for various garments and other materials. Modern machines feature computer controls to monitor functions like speed and stops.