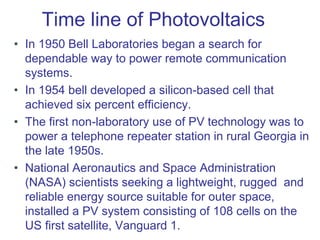

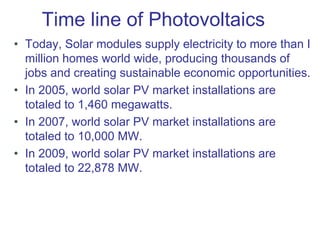

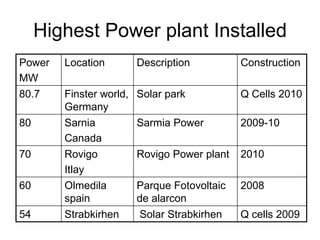

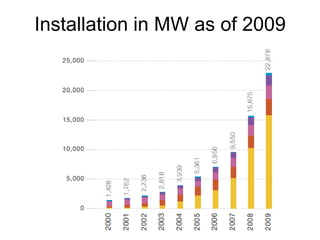

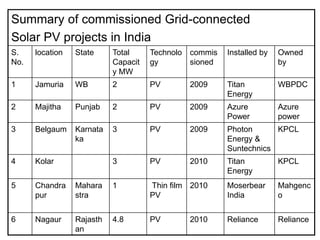

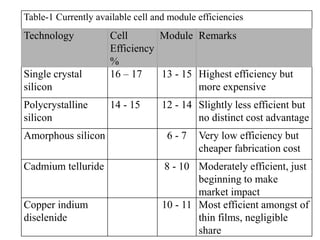

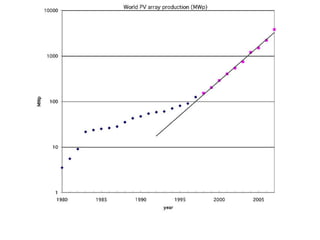

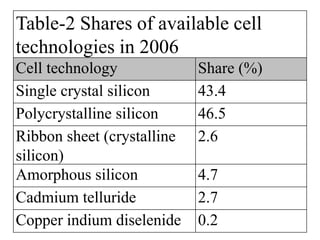

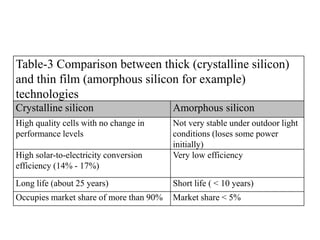

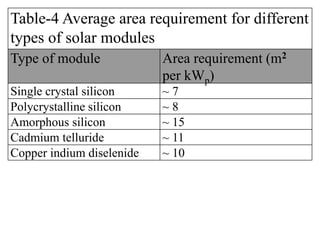

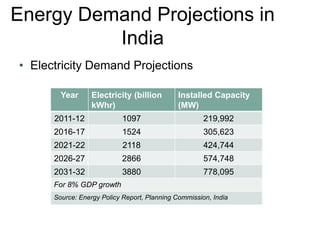

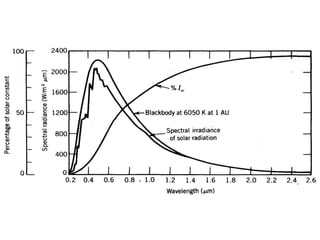

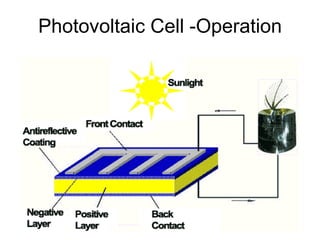

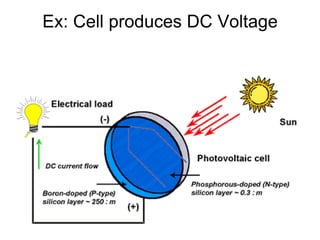

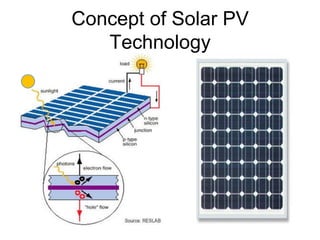

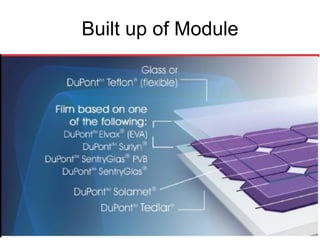

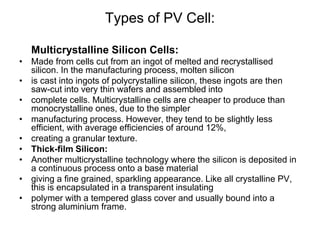

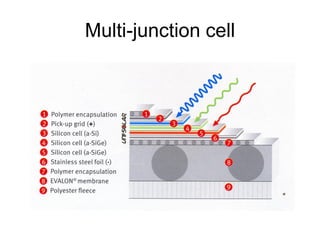

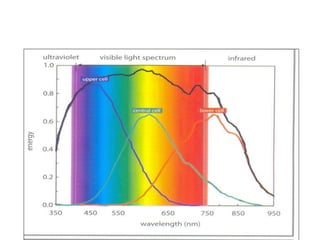

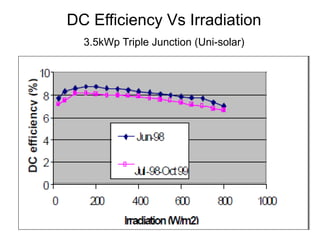

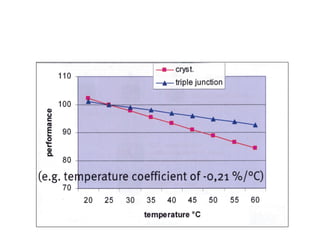

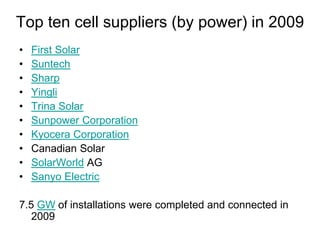

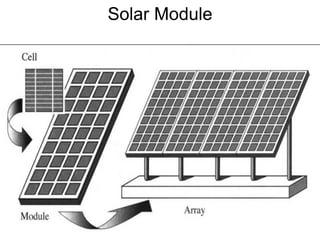

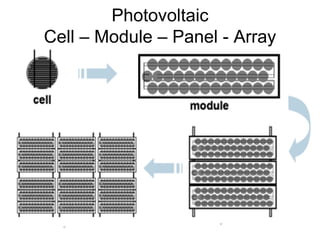

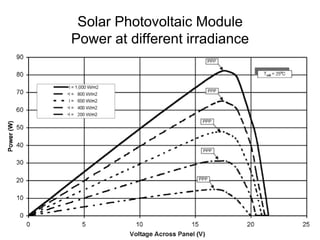

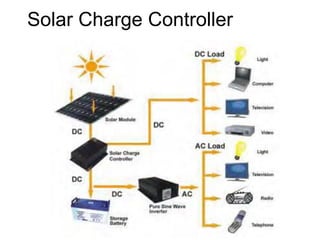

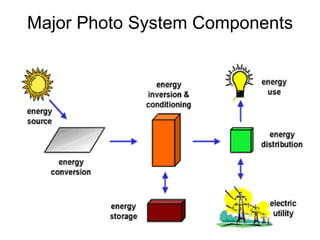

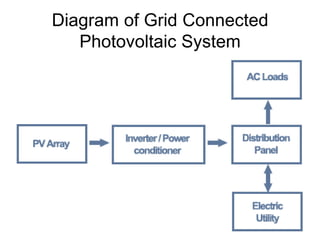

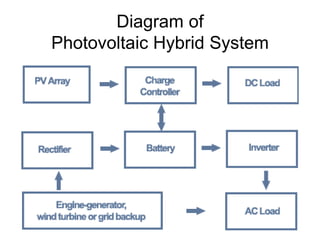

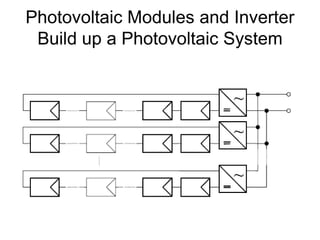

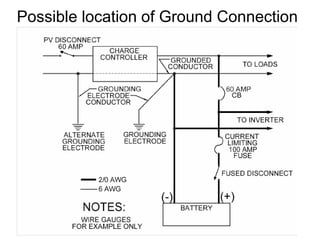

Solar photovoltaic energy principles involve converting sunlight into electricity through photovoltaic cells. The document discusses the history and development of photovoltaic technology from the 1800s to present day. It provides overviews of different photovoltaic cell technologies including crystalline silicon, thin film technologies, and multi-junction cells. Tables and diagrams are presented on topics like currently available cell efficiencies, market shares of cell technologies, area requirements for different module types, and the components that make up photovoltaic systems.