This document summarizes a presentation on designing a PV solar system for a house. It includes calculations to determine the necessary components of the system, including the number of solar panels, batteries, inverter size, and charge controller. An economic analysis compares the cost of the proposed PV system to an equivalent diesel generator system over a 30-year period, finding the PV system to be more cost effective. Wire sizing calculations are also included to determine appropriate wire gauges for connecting the system components.

![Economic Analysis

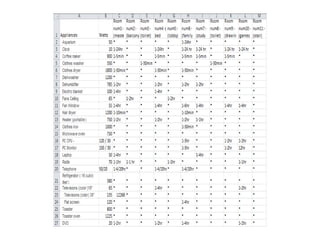

Cost Estimation For Solar System

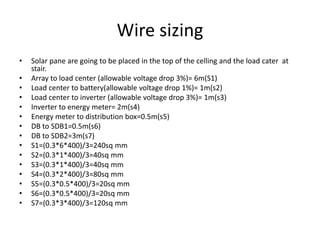

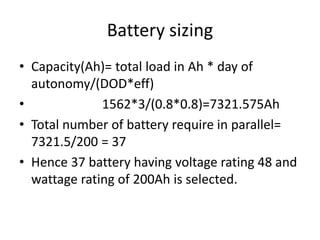

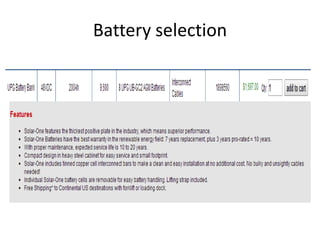

S.N Particulars Price/piece(NRs) Numbers Total price(NRs)

1 OME 48 Volt mono solar panel 7060 54 381240

2 Inverter 980000 1 980000

3 Charge Regulator 25578 11 281358

4 48 volt battery 166306 37 6153322

5 Transportation Cost 45000

6 Installation Cost 20000

Total 7860920

Total cost of installation = Rs.7860920/-

Total annual expenditure = Rs.2500/-

Net present worth for the PV system is calculated as:

NPW (PV system) = -7860920-6153322(P/F, 4%, 10) - 6153322 (P/F,

4%, 20) - 2500(P/A, 4%, 30)

[Since, batteries have to be replaced in

every ten years.]

= -7860920-4156963-2808295-43230

= NRs.-14869408/-](https://image.slidesharecdn.com/solarhouse1-140510155402-phpapp02/85/PV-system-design-for-house-22-320.jpg)

![• NPW (Diesel-generator) = -138000-138000(P/F, 4%, 10)

- 138000(P/F, 4%, 20) - 994625 (P/A, 4%, 30) –

1500(P/A, 4%, 30)

• [Since, diesel generator works properly for about

10 years, we need 3 generators during 30 years of

period.]

• = -138000-93227-62981-17199088-25938

= NRs.17519234/-

• The NPW of diesel generator is greater than that of PV

system. Hence, the PV system is financially feasible

compared to diesel generator.](https://image.slidesharecdn.com/solarhouse1-140510155402-phpapp02/85/PV-system-design-for-house-24-320.jpg)