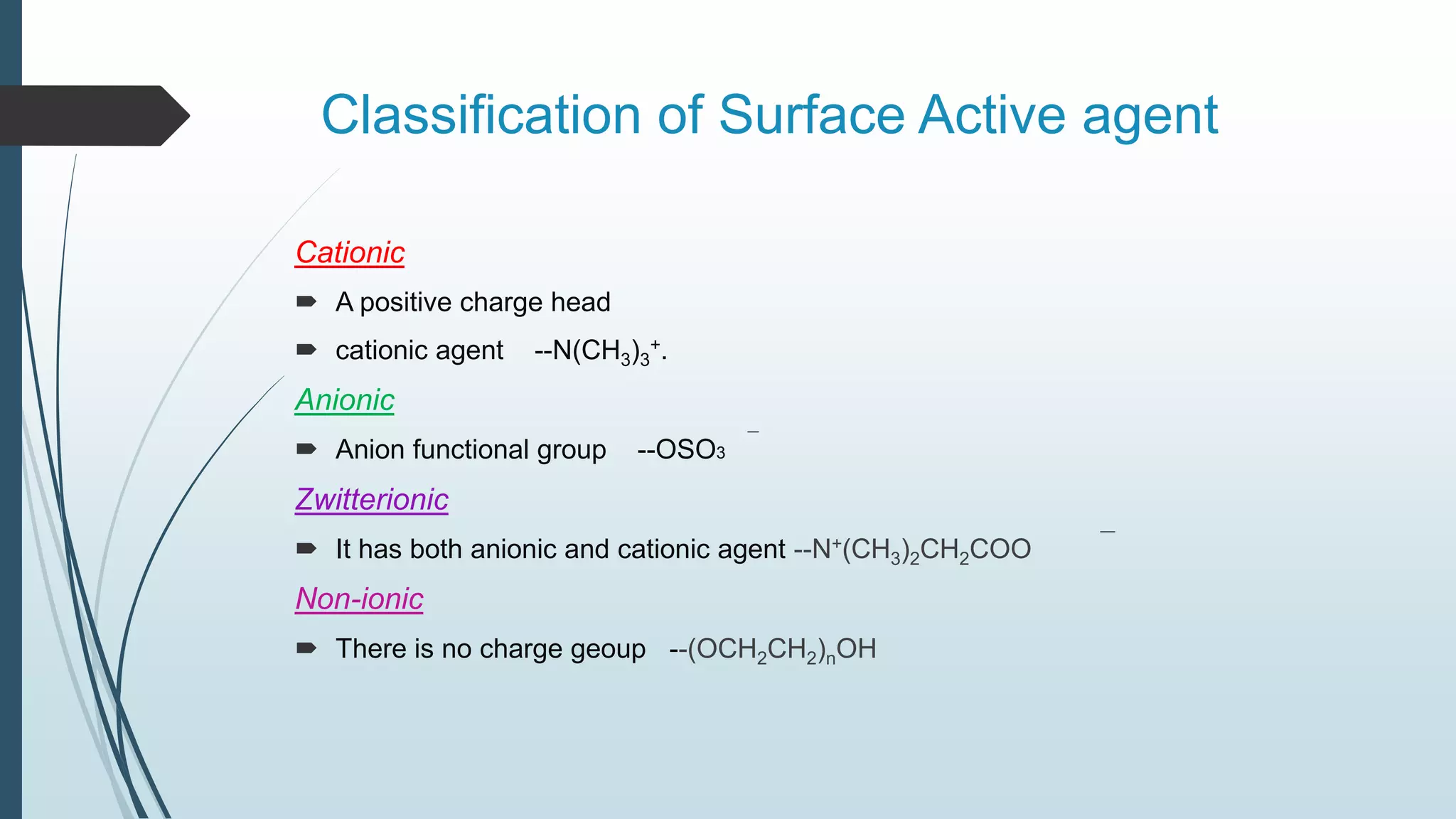

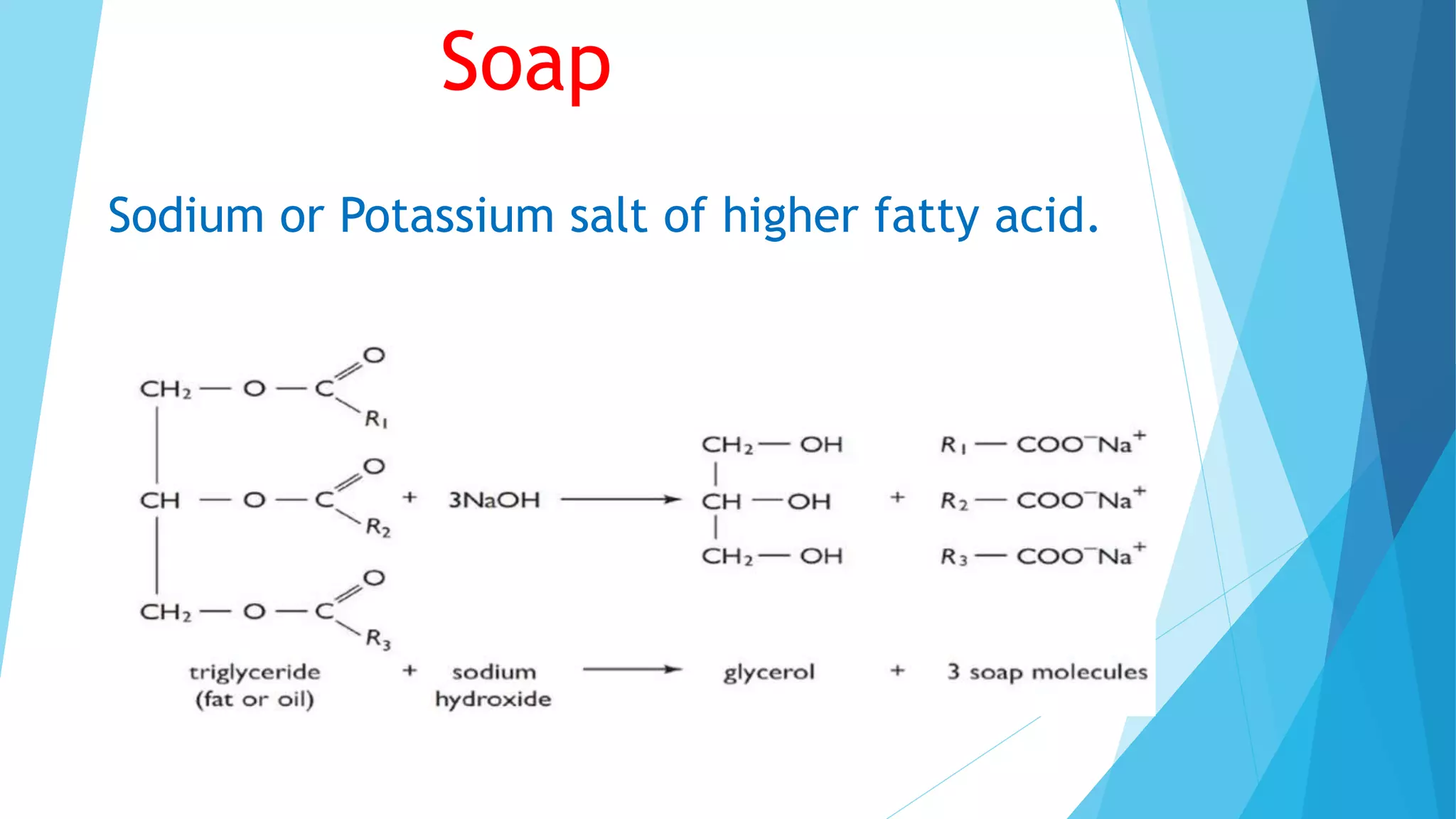

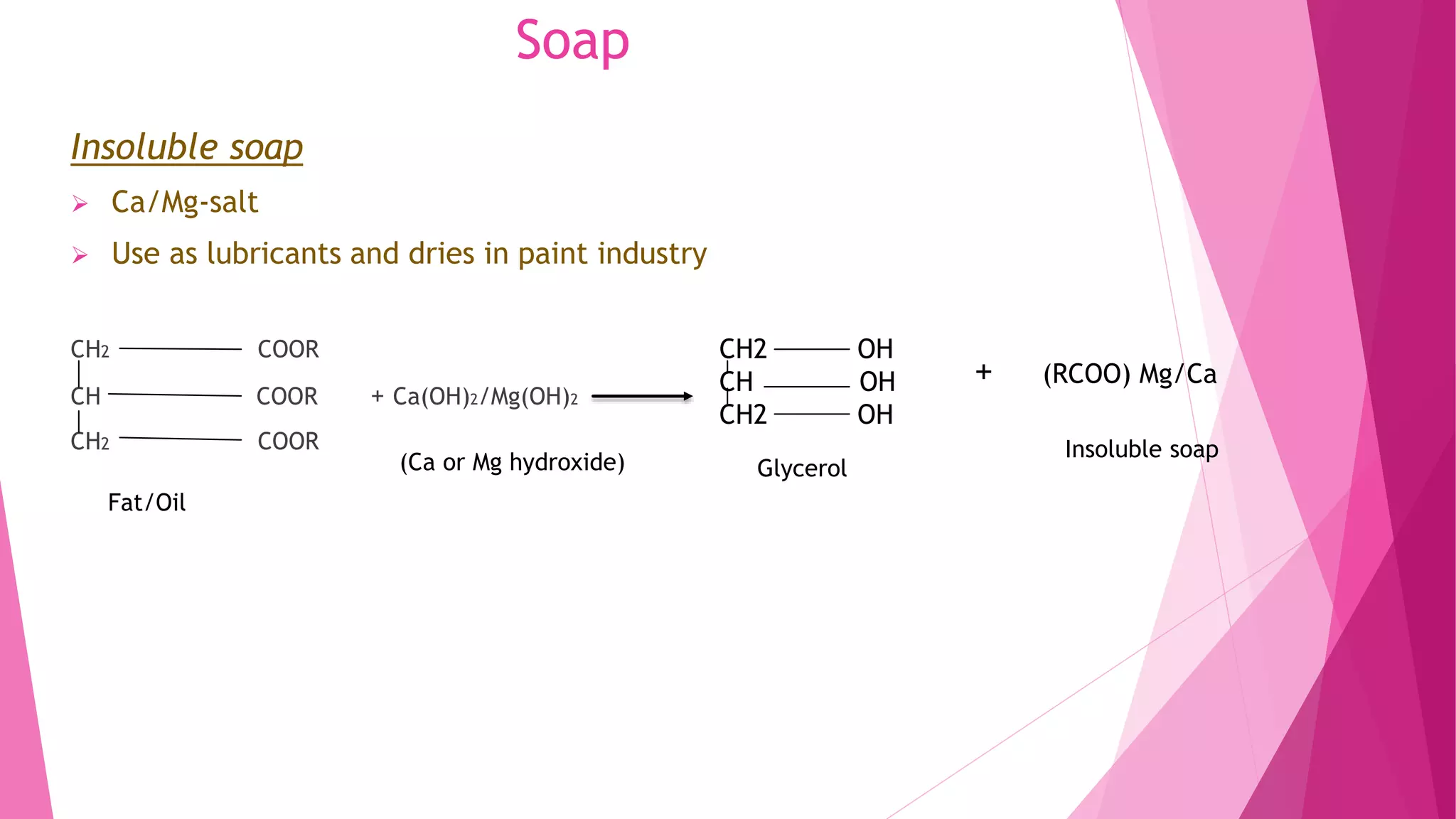

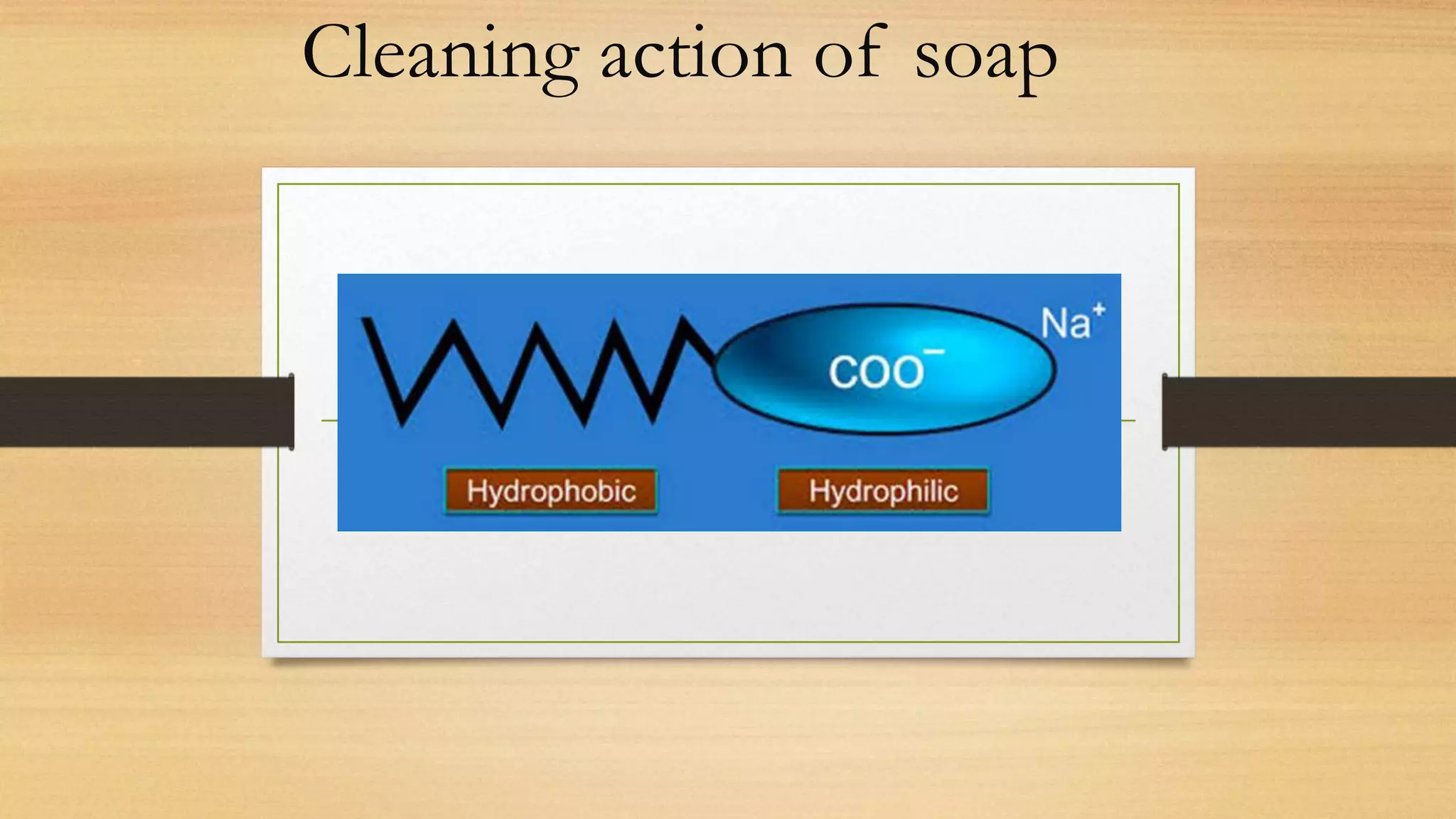

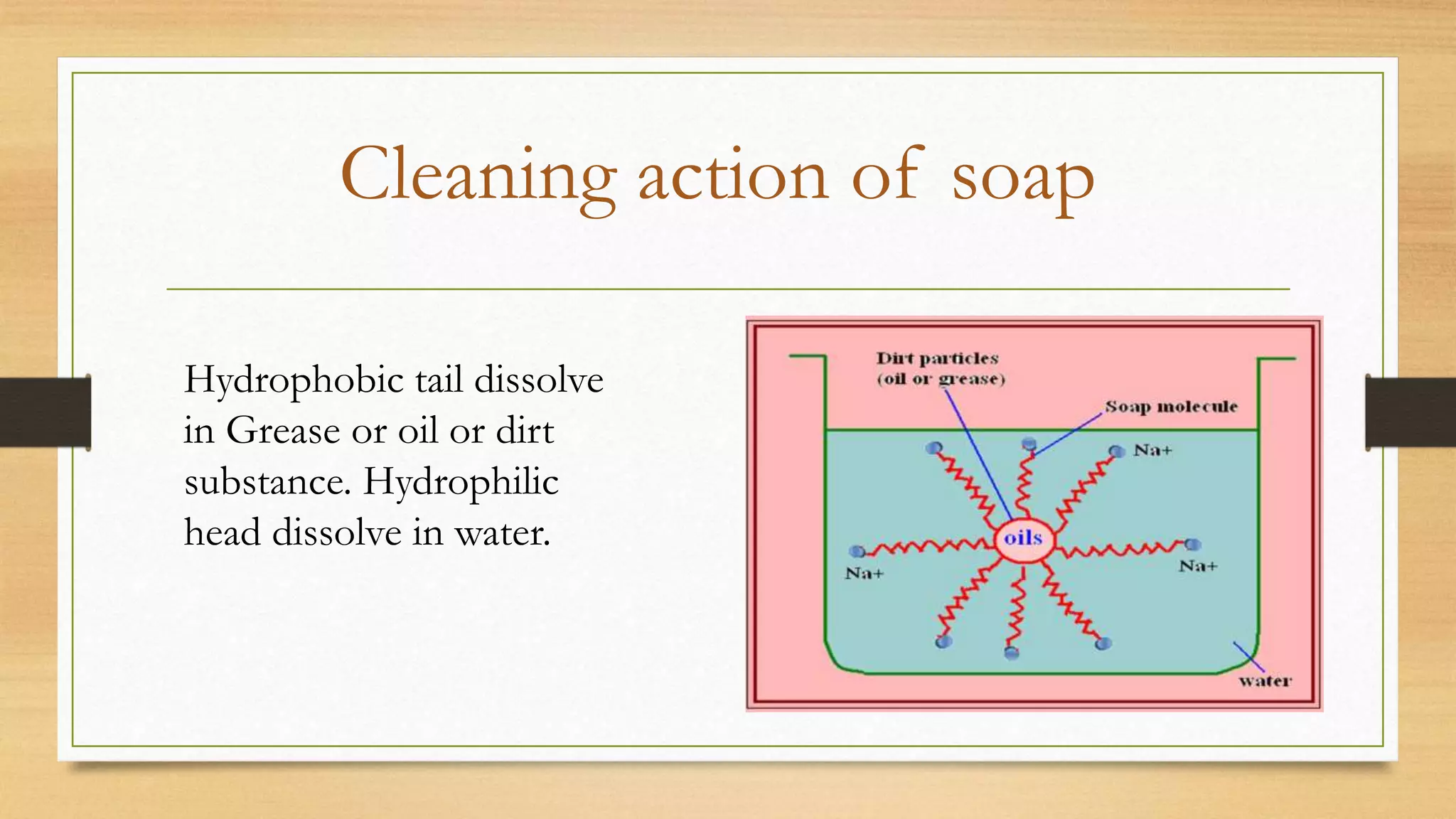

This document introduces Habibur Rahman and their student ID number. It then discusses surface active substances, including their definition and how they lower the surface tension of water. It classifies surface active agents into four categories: cationic, anionic, zwitterionic, and non-ionic. Soap is introduced as a sodium or potassium salt of higher fatty acids. Soaps are classified as hard, soft, or insoluble. Hard soap is moderately soluble in water, soft soap dissolves in water, and insoluble soap is used as a lubricant. The cleaning action of soap is explained by how the hydrophobic tail dissolves in grease/oil/dirt while the hydrophilic head dissolves