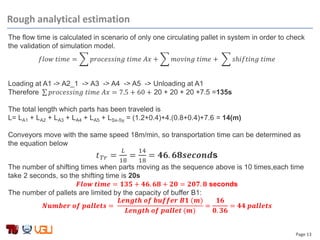

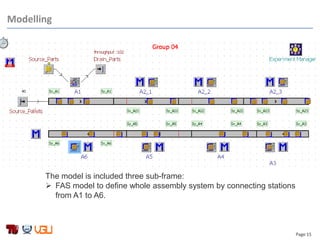

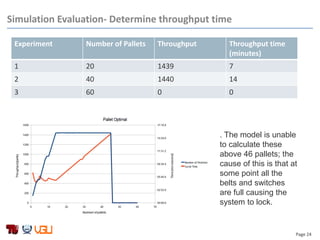

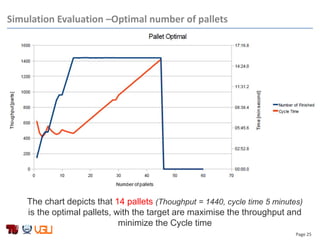

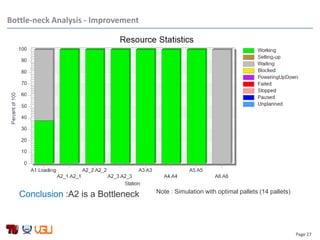

This document summarizes a group project on simulating a flexible assembly system. It includes an agenda, descriptions of the system components and process flow, details on building the simulation model such as the database structure and validation process, and results from running simulation experiments with different numbers of pallets. The evaluation found that 14 pallets provided the optimal throughput and cycle time. A bottleneck analysis identified station A2 as the bottleneck. Two options for improving the system by adding more A2 stations were presented and adding one additional A2 station was recommended.

![Page 28

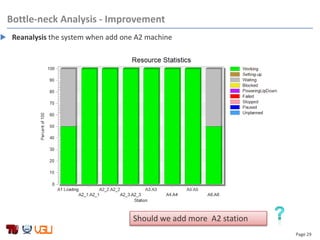

Add one Station A2 :

Bottle-neck Analysis – Improvement : Option 1

* Capacity = 2

0

500

1000

1500

2000

2500

0 10 20 30 40 50 60

Thoughput[Parts]

Num of Pallets [Pallets]

4 Station A2

Optimal pallets = 21 pallets

increase 7 Pallets

Thoughput = 1920 parts

Increase 480 parts](https://image.slidesharecdn.com/simulationofflexibleassemblysystemusingtecnomatix-140730034619-phpapp02/85/Simulation-of-flexible-assembly-system-using-tecnomatix-28-320.jpg)

![Page 30

0

500

1000

1500

2000

2500

0 10 20 30 40 50 60 70

Thoughput[Parts]

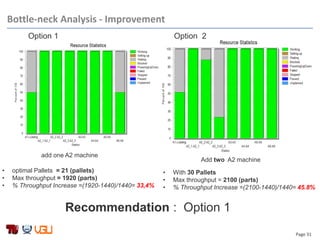

5 Station A2

Add two A2 machines:

Bottle-neck Analysis – Improvement – Option 2

* Capacity = 3

Optimal pallets = 30 pallets

increase 9 Pallets

Thoughput = 2100 parts

Increase 180 parts](https://image.slidesharecdn.com/simulationofflexibleassemblysystemusingtecnomatix-140730034619-phpapp02/85/Simulation-of-flexible-assembly-system-using-tecnomatix-30-320.jpg)

![Page 34

References

[VDI-3633] Association of German Engineers. Simulation of systems in materials

handling, logistics and production: Fundamentals. 2010. Beuth Verlag,

Berlin.

[Book] Walter Terkaj, Tullio Tolio, Anna Valente.Design of Flexible Production

Systems.(2009).

[Book] Steffen Bangsow. Manufacturing Simulation with Plant Simulation

and SimTalk. (2009)

[Self-Guided

Script]

Azrul Azwan Abdul Rahman, Bastian Muller. Tecnomatix Plant

Simulation 11. Version 15.06.2014](https://image.slidesharecdn.com/simulationofflexibleassemblysystemusingtecnomatix-140730034619-phpapp02/85/Simulation-of-flexible-assembly-system-using-tecnomatix-34-320.jpg)