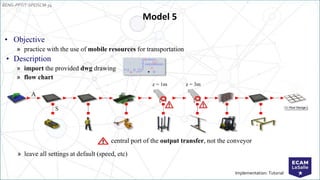

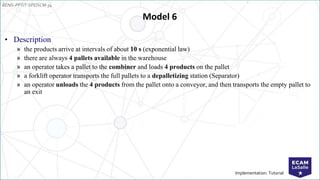

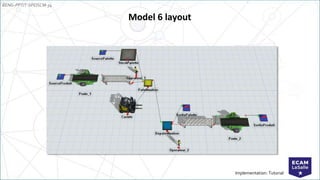

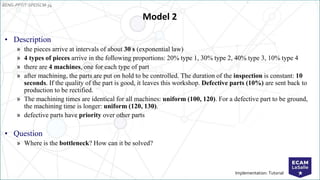

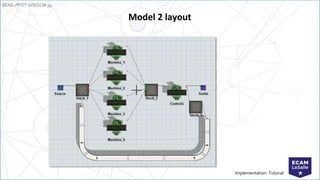

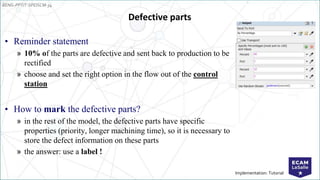

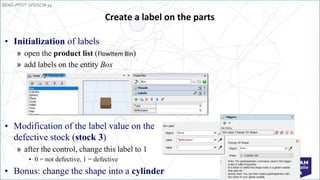

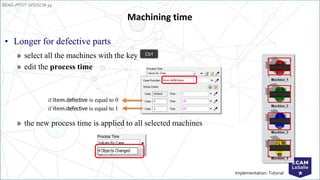

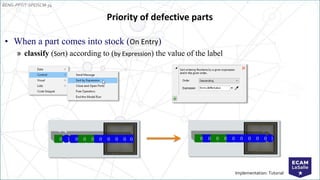

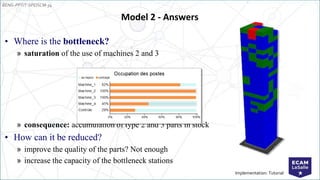

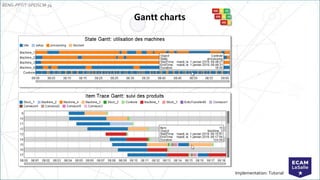

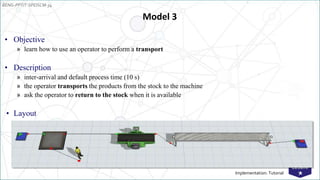

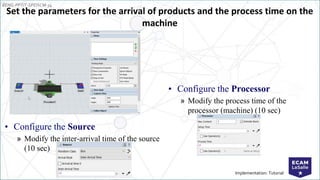

This document describes a training tutorial for using Flexsim software to model manufacturing processes. It includes instructions on modeling different resources like sources, queues, processors, and conveyors. It also provides an example modeling assignment involving parts with different types being routed to specific machines with some parts being defective and requiring longer processing times. The bottleneck in the example model is identified as machines 2 and 3 becoming saturated, causing an accumulation of parts in the associated stock areas.

![EENG-PPT/T-SPEISCM-34

Implementation: Tutorial

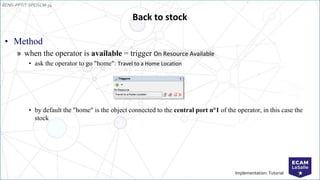

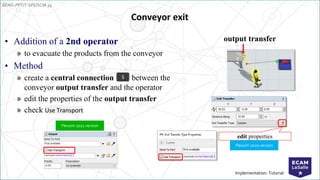

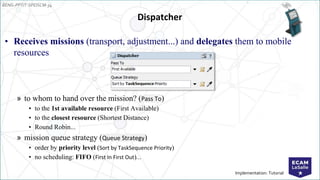

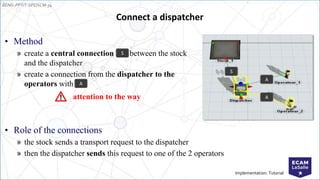

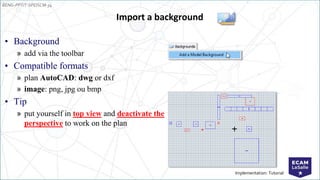

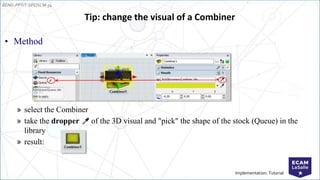

• Method

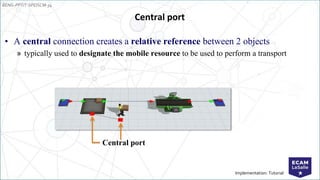

» create a central connection between the stock and the operator

» select the stock and check Use Transport

• by default, the resource used for transport is the object connected to the central port n°1 of the stock,

designated by the expression current.centerObjects[1]

Transport by a mobile resource

S](https://image.slidesharecdn.com/flexsim2-240325020541-896263b4/85/FLexsim-2-Car-vehicle-automotive-engine-pptx-44-320.jpg)