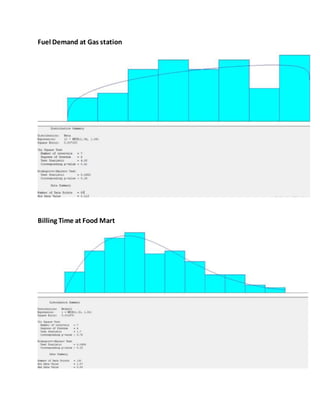

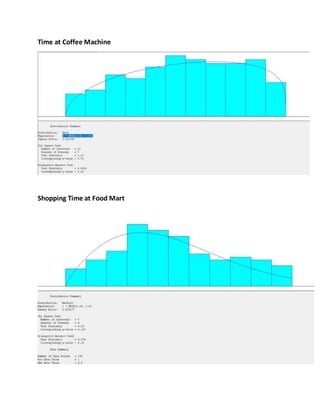

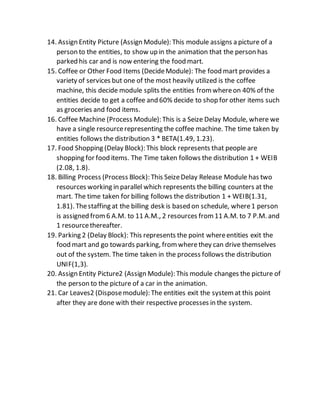

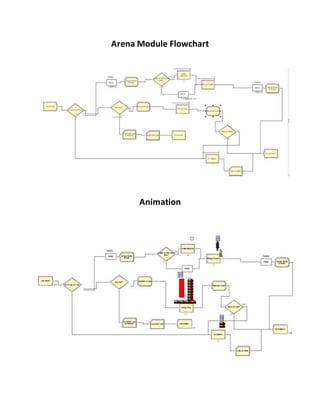

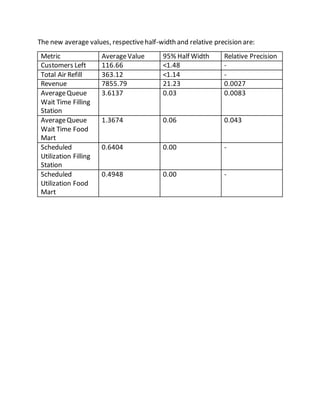

The document describes a simulation of a Shell gas station, convenience store, and air pump located in Cincinnati, Ohio using Arena software. Data was collected on arrival patterns and service times. The simulation models customer flow between the gas station, food mart, and air pump based on probabilistic distributions. Key metrics like customers leaving due to long queues, total revenue, resource utilization, and wait times will be analyzed to identify opportunities to improve the Shell's operations.