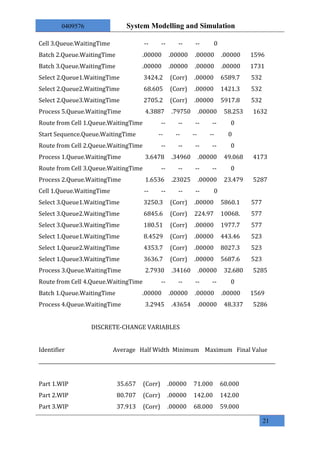

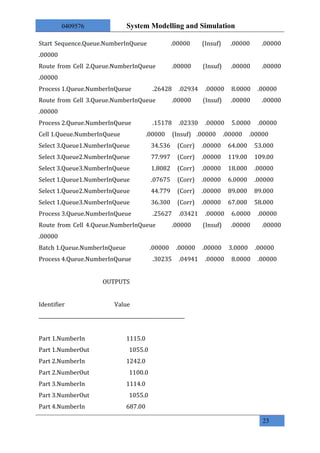

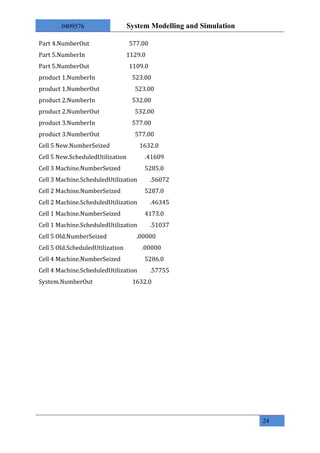

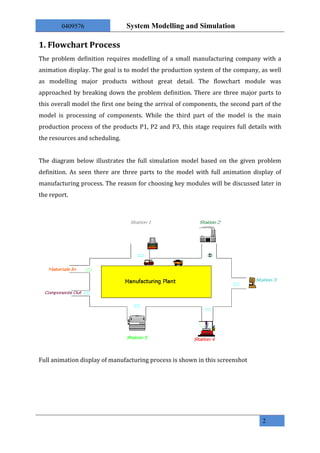

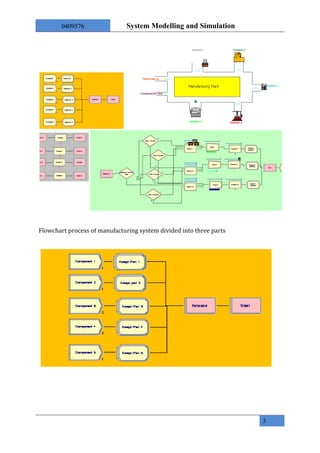

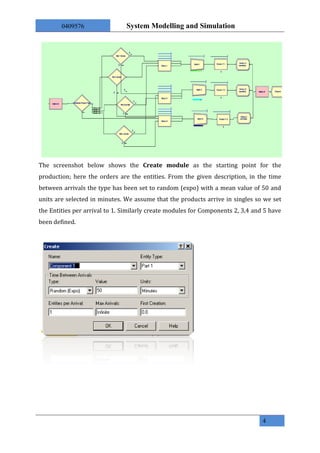

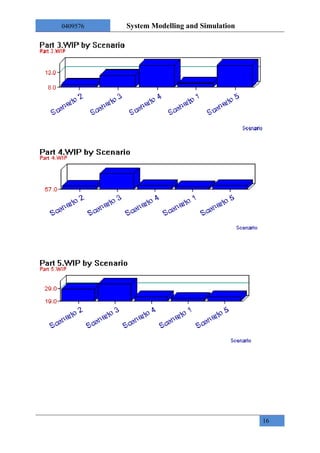

This document summarizes the results of simulating a manufacturing system model with three parts: arrival of components, processing of components, and the main production process. The simulation found a bottleneck at machine 2, with the longest queue times. Several proposals to improve system performance were explored using a process analyzer tool, with scenario 2 found to spread queue times more evenly and reduce bottlenecks at a reasonable cost, and scenario 5 found to give the best results by further reducing wait times and balancing utilization across resources.

![0409576 System Modelling and Simulation

18

7. References

[1]. Dr Ali Mousavi Notes and Model Examples, (1/12/08)

http://people.brunel.ac.uk/~emstaam/ .

[2]. David W. Kelton; Randall Sadowski ; David T Sturrock, Simulation with Arena (4th

edition).

[3]. Arena 10.0 Software, Arena Online Help.](https://image.slidesharecdn.com/systemsmodellingandsimulation-150118143304-conversion-gate01/85/Systems-modelling-and-simulation-18-320.jpg)