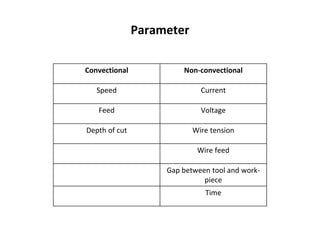

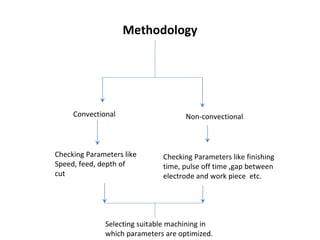

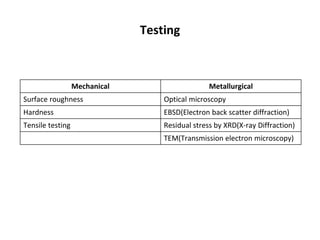

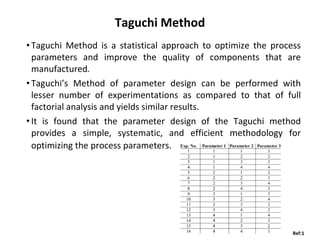

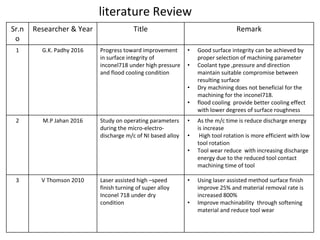

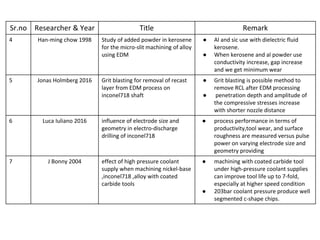

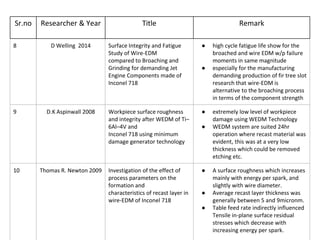

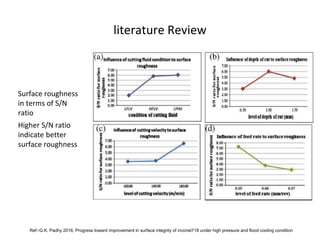

Traditional machining of Inconel 718 generates residual stresses and lower surface quality compared to non-traditional machining. Non-traditional methods like EDM and laser machining produce better surface integrity with minimal damage. The document reviews different studies on optimizing machining parameters for conventional turning and EDM of Inconel 718 to maximize material removal rate while minimizing surface roughness and recast layer thickness.