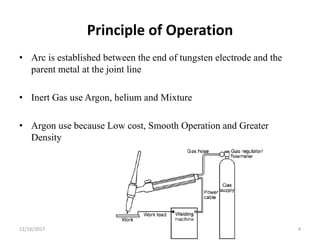

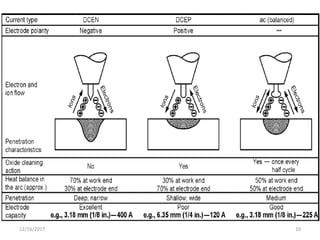

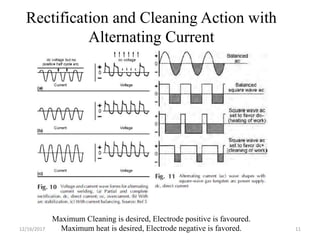

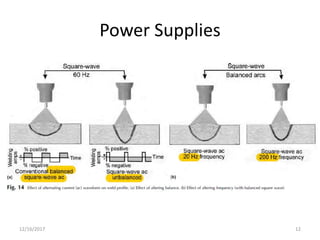

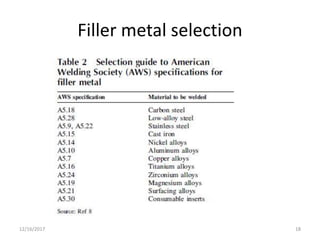

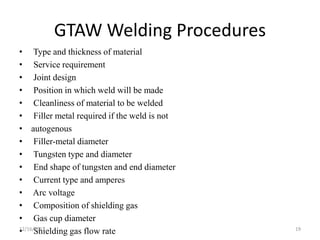

The document discusses gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding. It describes the principle of using an arc between a tungsten electrode and the base metal to melt and join materials. Inert shielding gases like argon are used to protect the weld area. GTAW can be used to weld materials like aluminum, stainless steel, and mild steel. It is well-suited for thin materials and high quality welds but has lower deposition rates than other welding processes. Electrode selection, filler metals, power supplies, safety procedures, and other aspects of the GTAW process are also outlined.