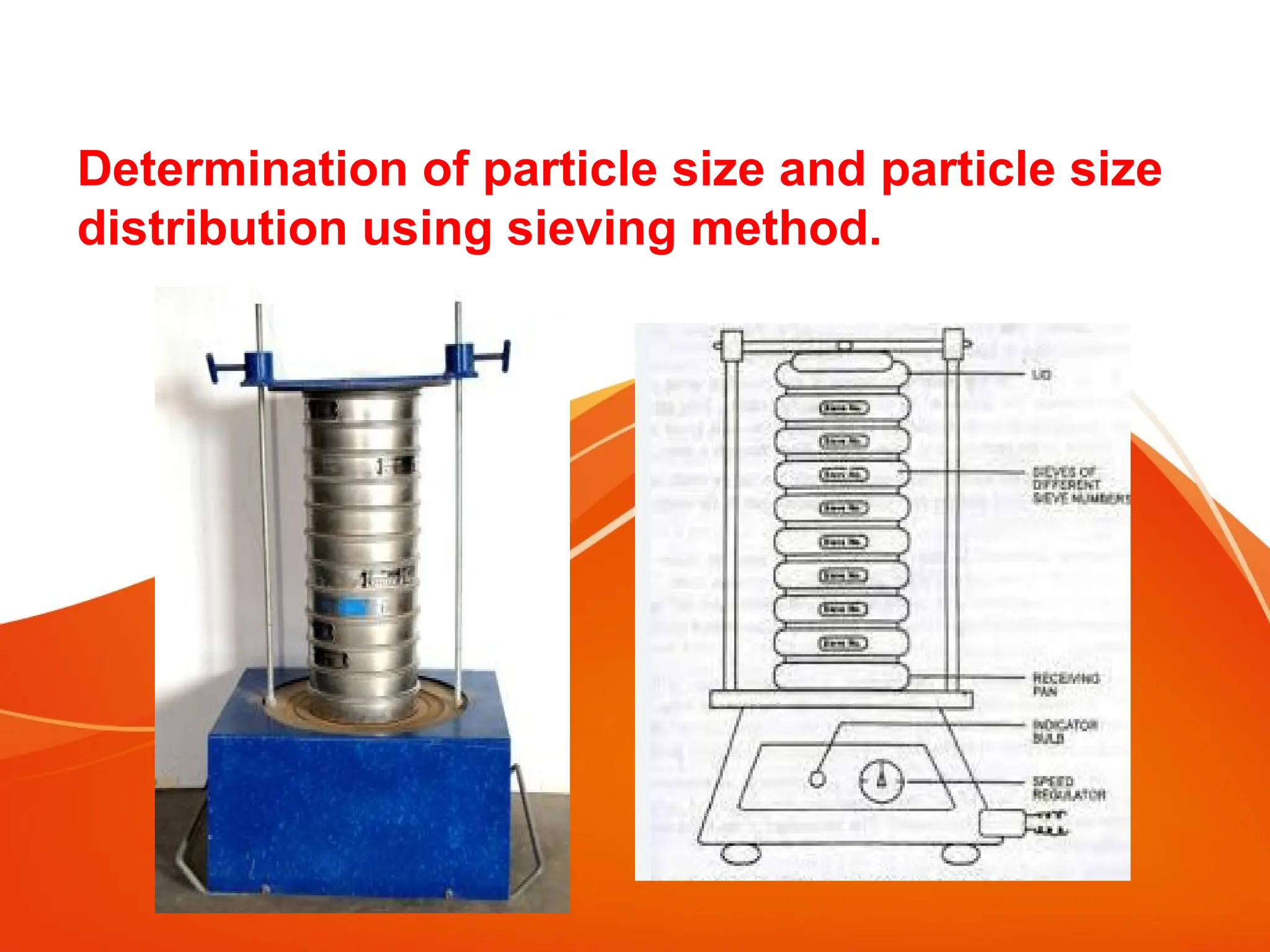

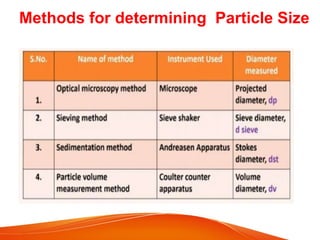

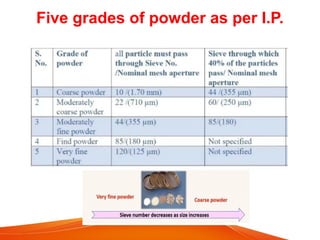

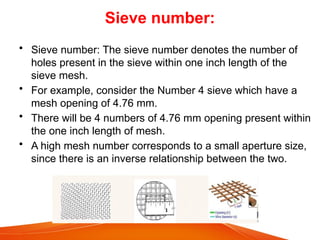

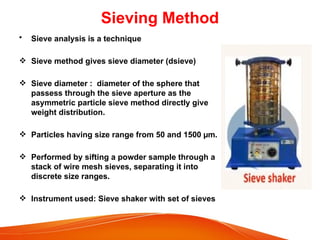

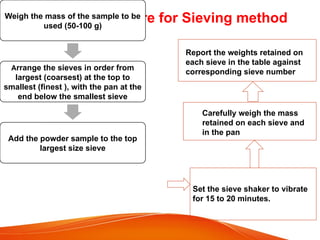

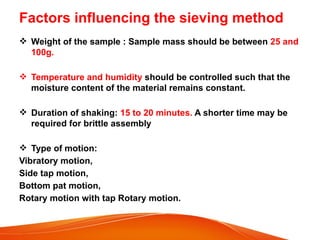

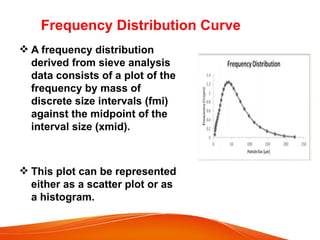

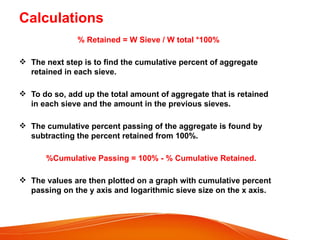

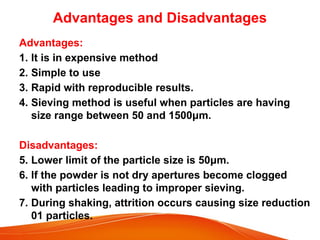

The document details the determination of particle size and distribution using the sieving method, highlighting the necessary chemicals, glassware, and apparatus required. It explains the importance of knowing not only particle size but also the distribution to understand their effects on dosage forms, and outlines the procedure for conducting sieve analysis, including factors that influence results. Advantages and disadvantages of the method are discussed, emphasizing its simplicity, cost-effectiveness, and limitations regarding lower particle size and potential for clogging.