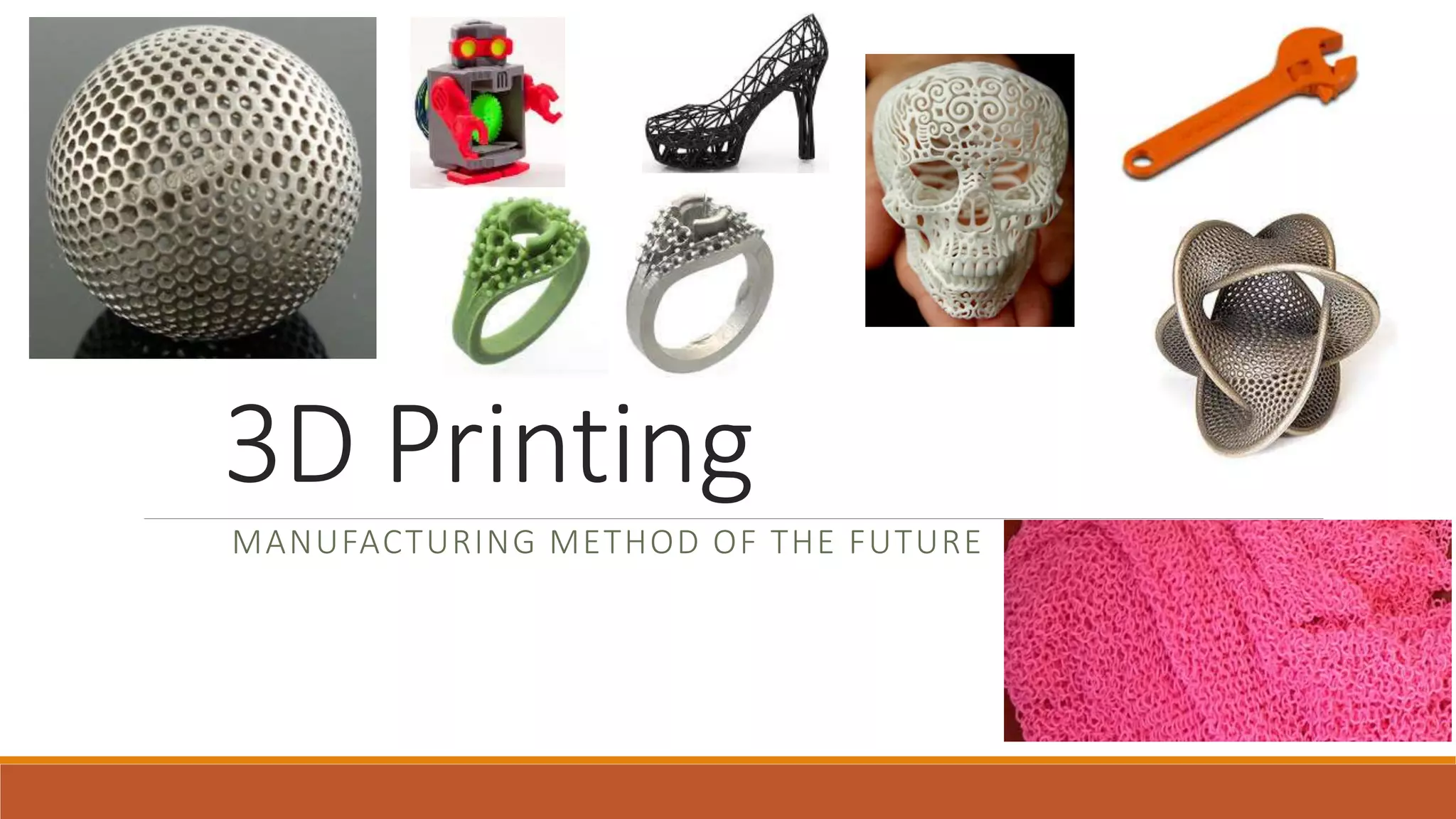

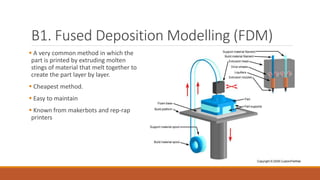

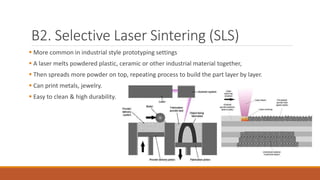

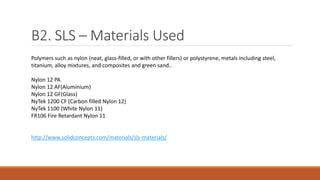

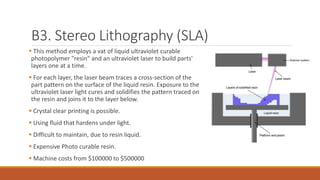

This document discusses 3D printing as a new manufacturing method that builds 3D objects by laying down successive layers of material. It describes the main 3D printing technologies of fused deposition modeling, selective laser sintering, and stereolithography. Fused deposition modeling works by extruding molten plastic filaments layer by layer, while selective laser sintering uses a laser to melt and fuse powdered materials. Stereolithography employs an ultraviolet laser to cure liquid resin into layers. The document outlines the materials used in each method and notes potential applications in industries like defense, aerospace, automotive, and biomedical.