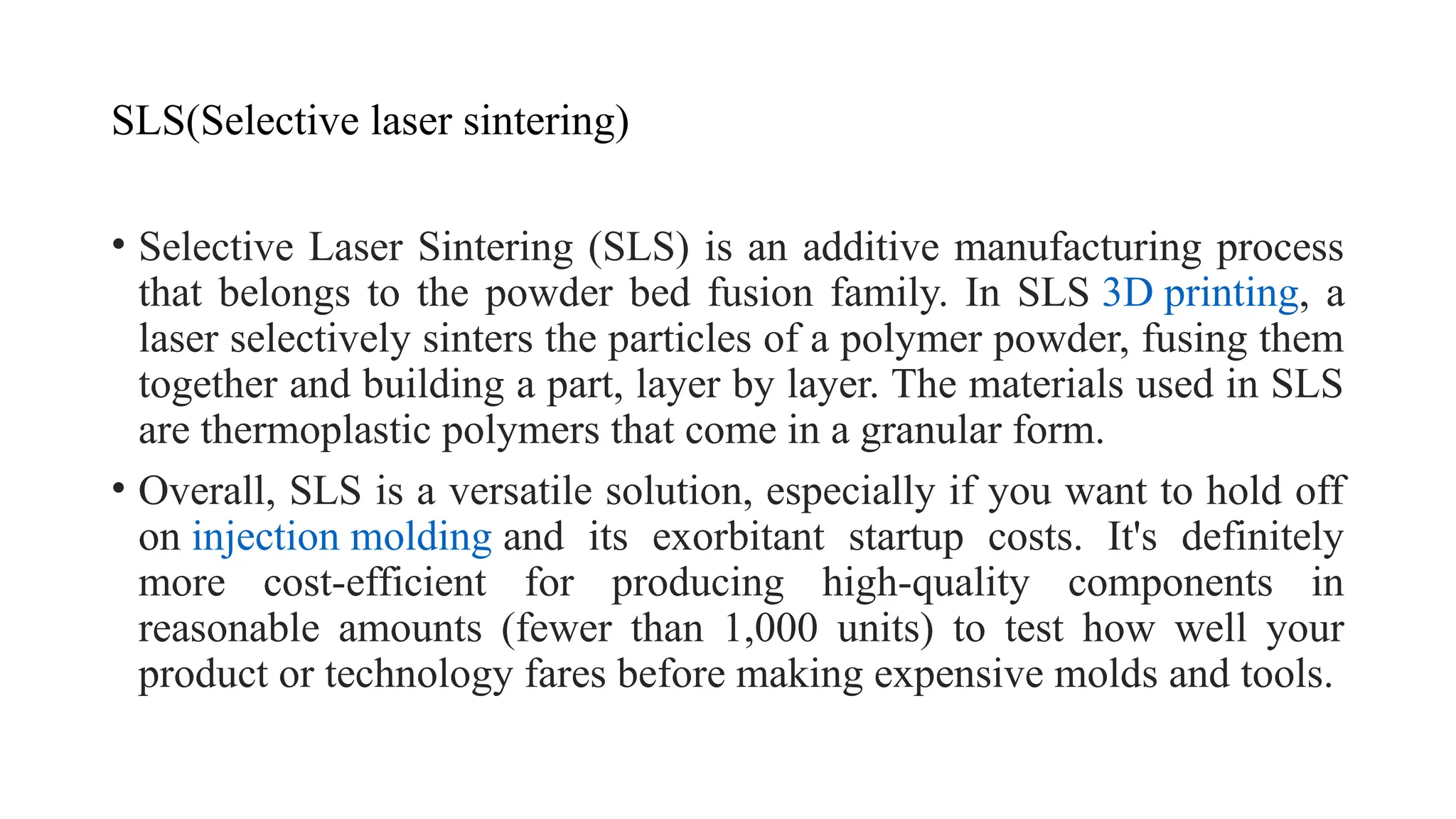

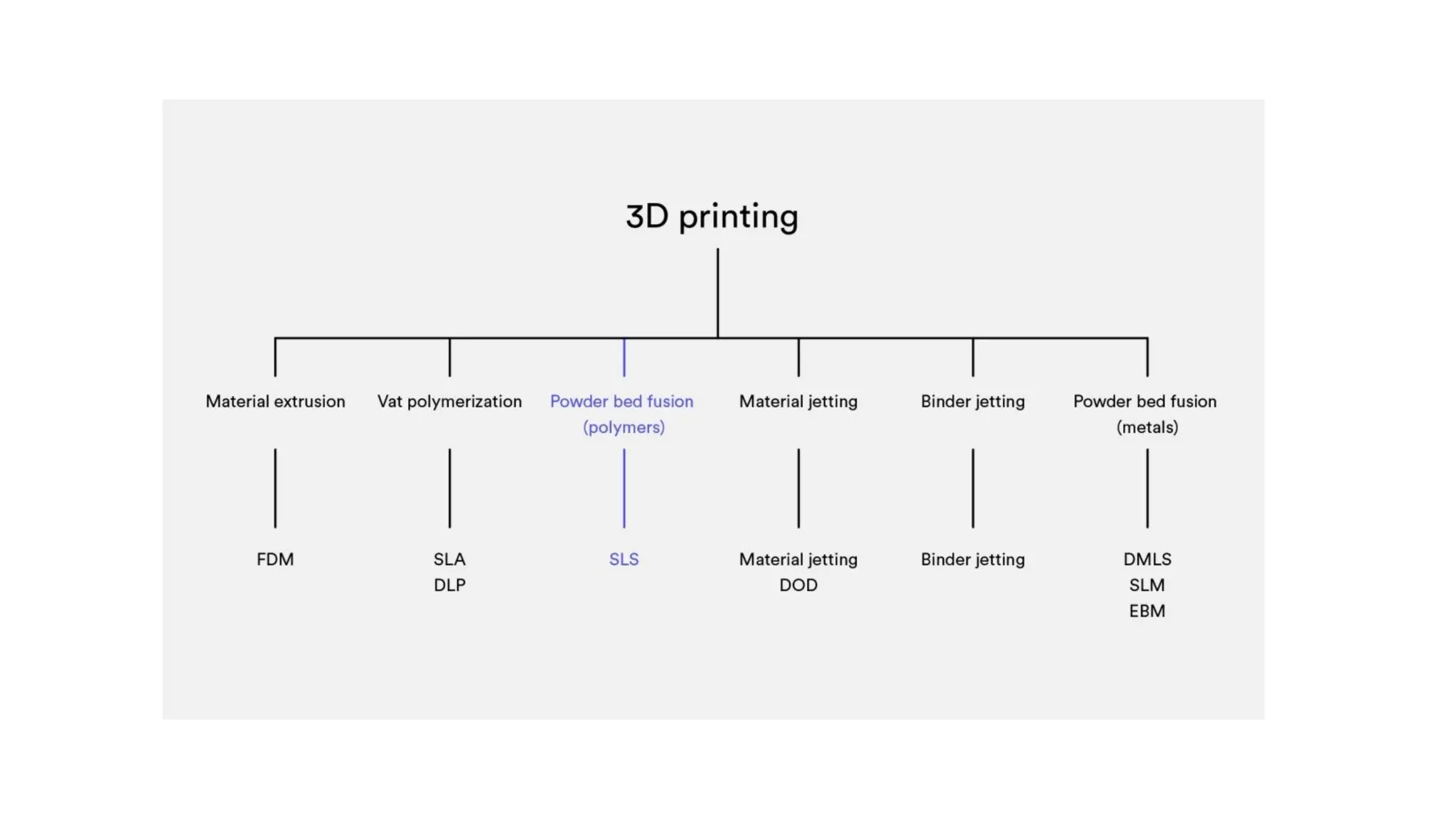

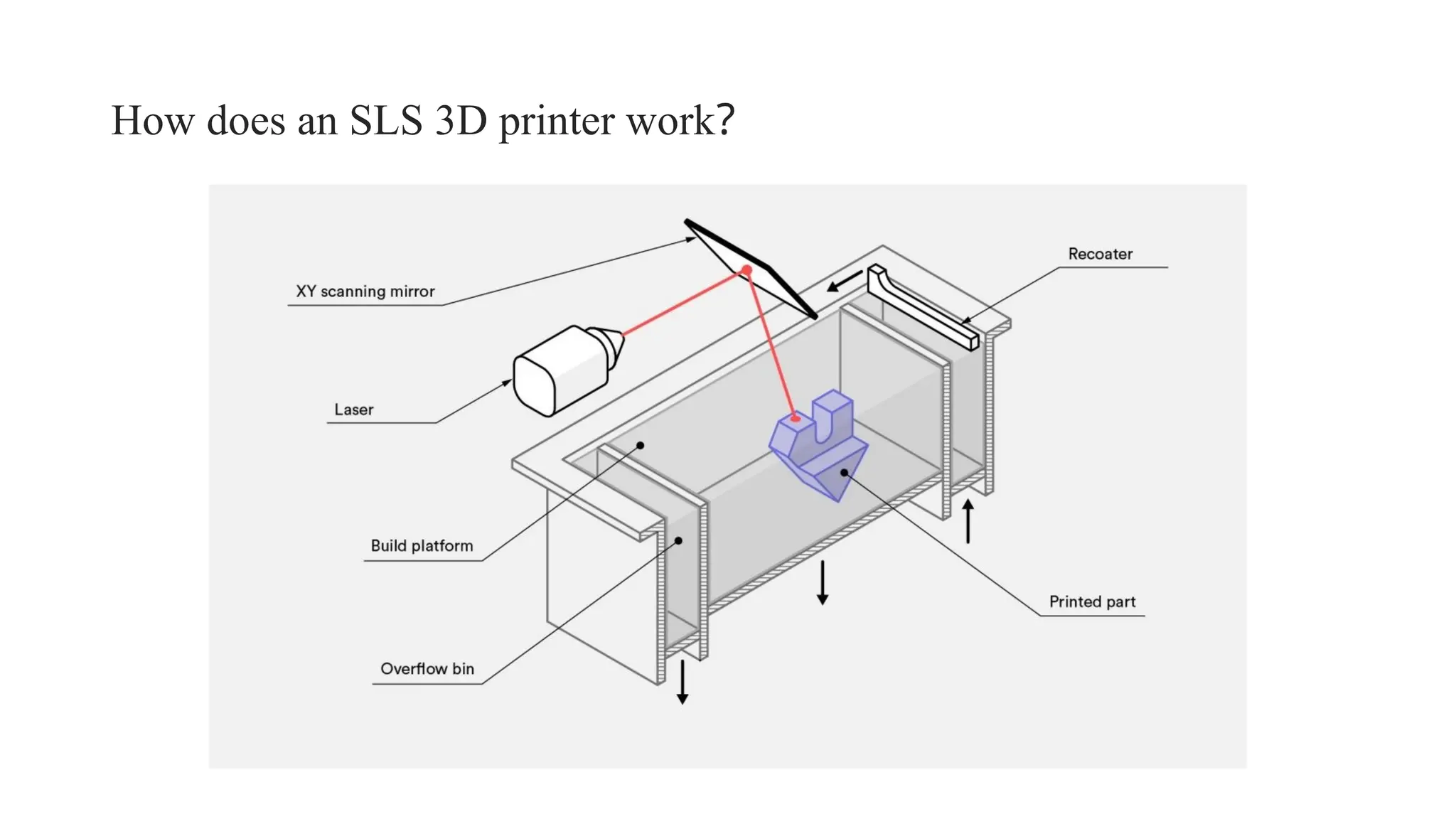

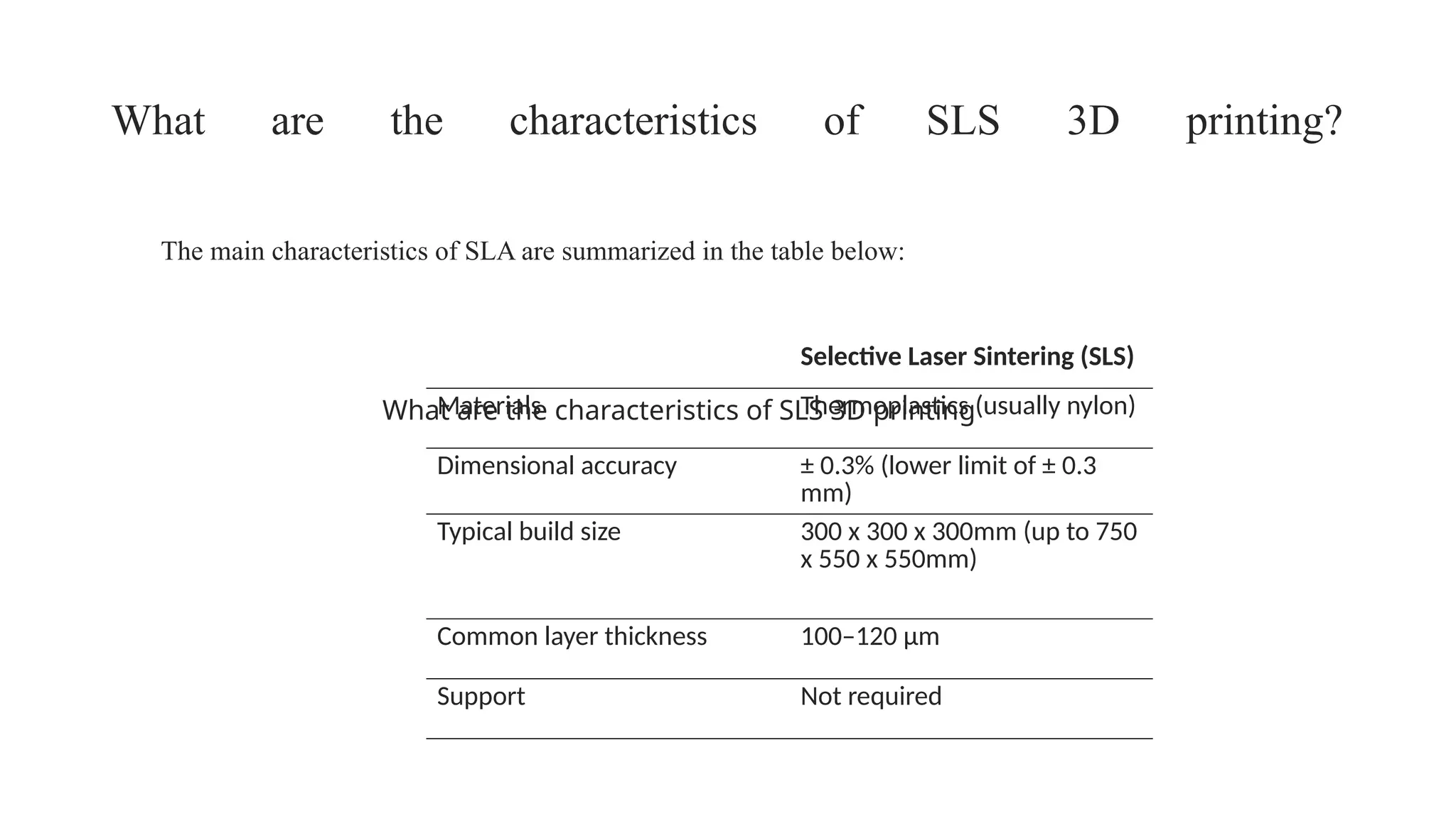

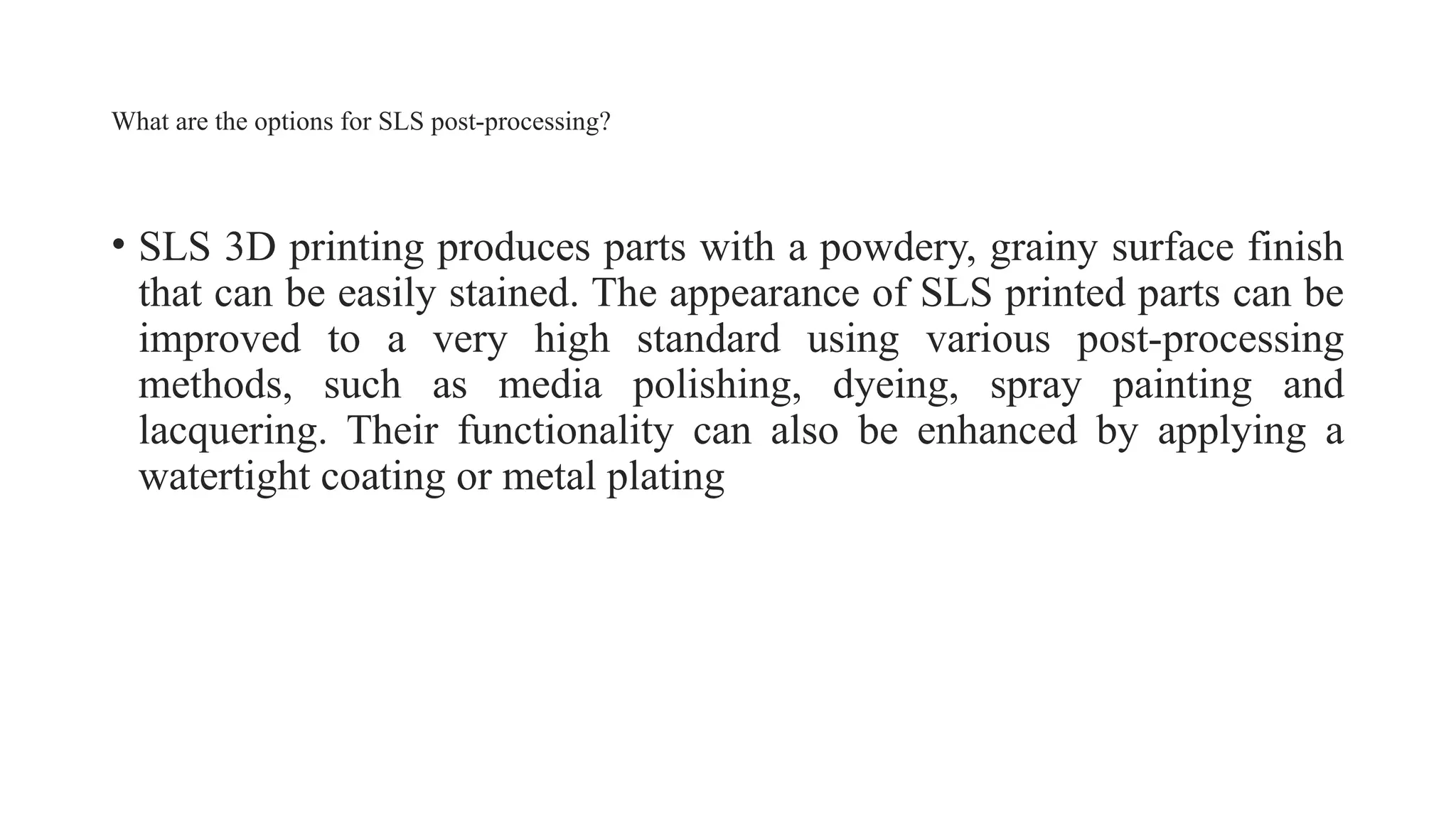

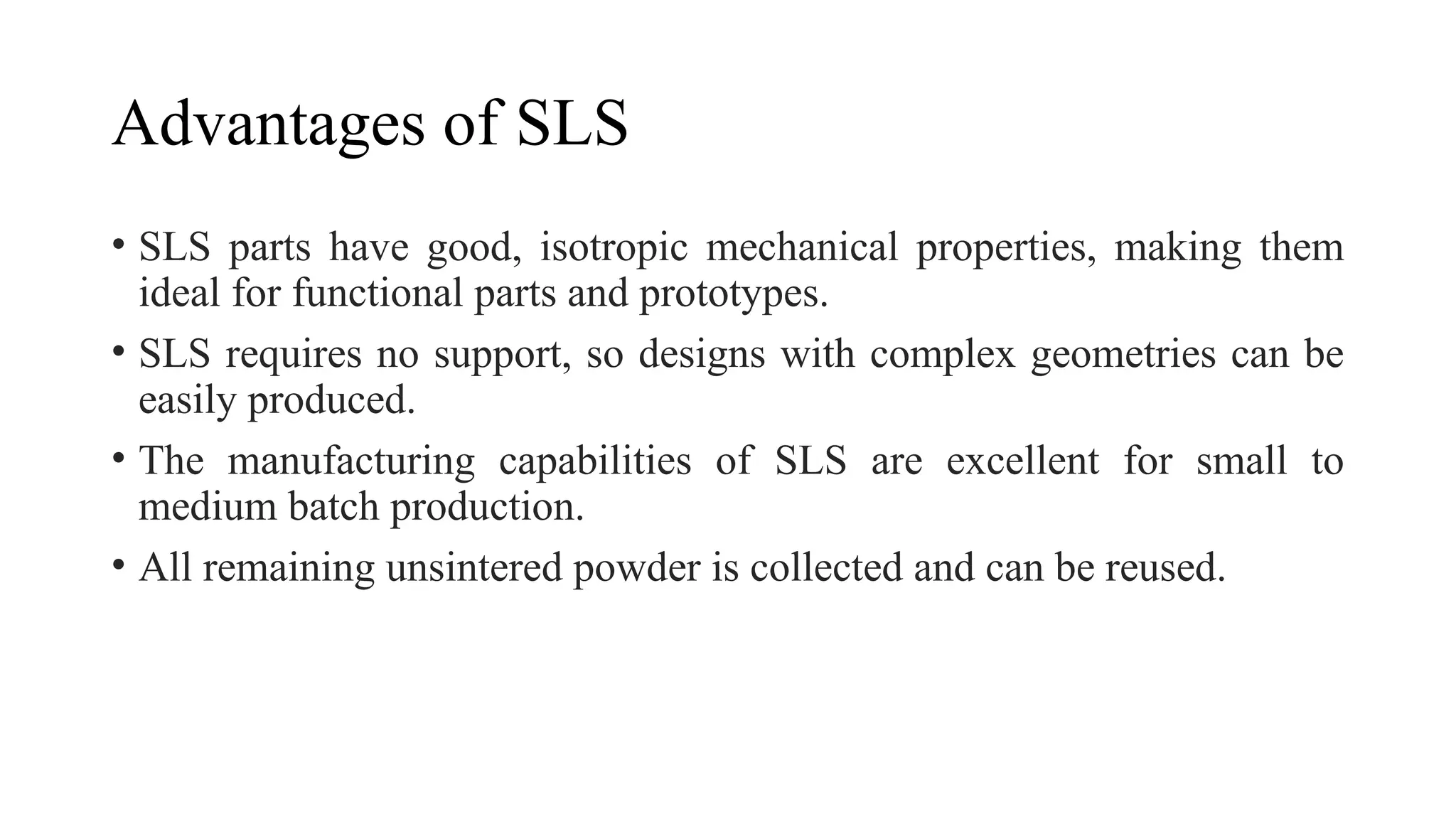

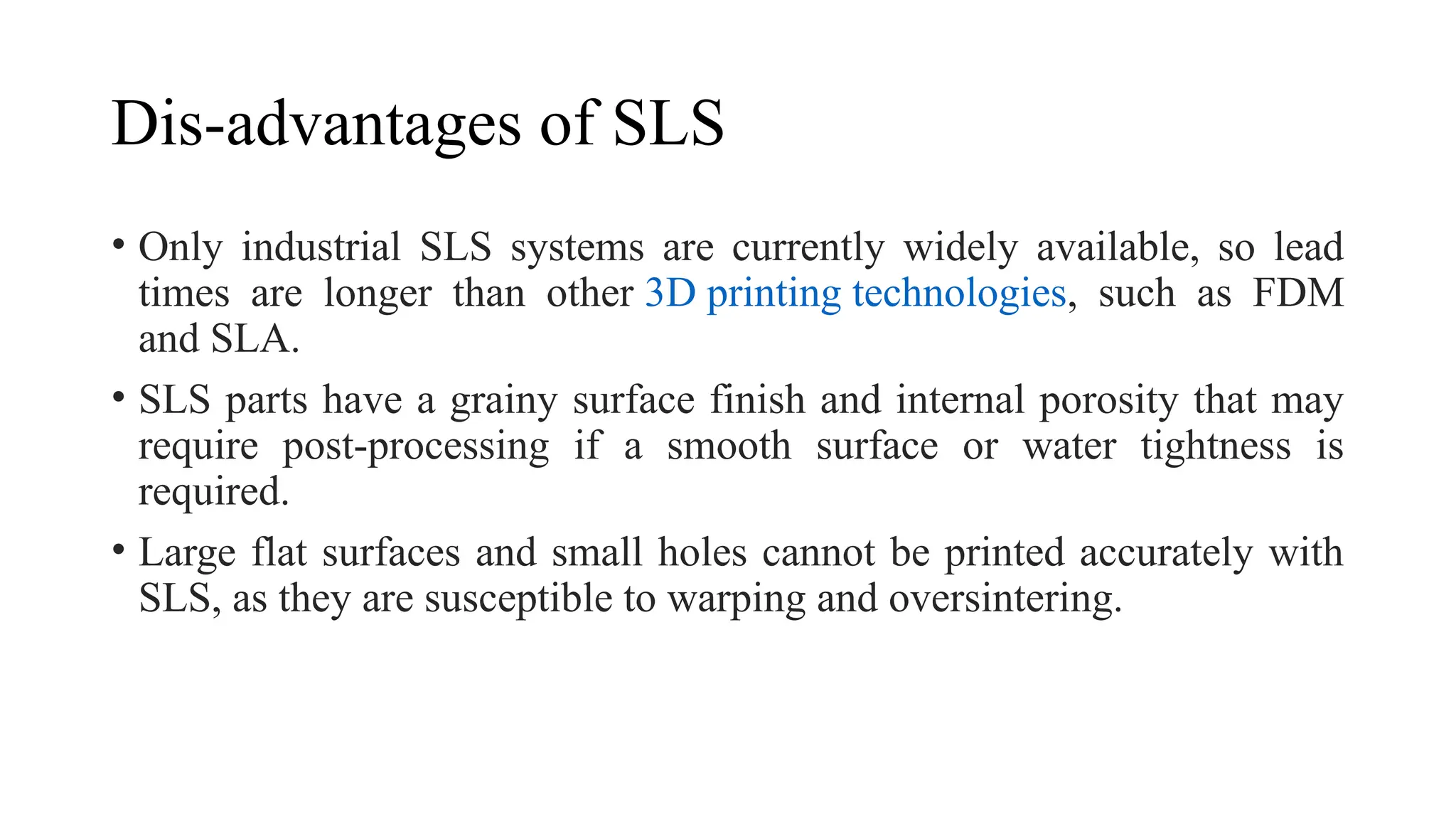

Selective laser sintering (SLS) is an additive manufacturing process that uses a laser to fuse polymer powder particles layer by layer, offering a versatile and cost-efficient method for low-production runs and prototyping functional parts without requiring support structures. SLS parts provide good isotropic mechanical properties, but may experience issues like shrinkage, warping, and a grainy surface finish that necessitates post-processing. The technology is primarily used in various industries, including aerospace, medical, and tooling, making it suitable for complex designs and small to medium batch production.