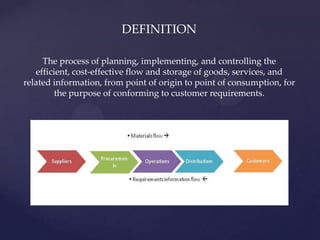

Logistics involves managing the flow of goods and information from suppliers to customers. It includes transportation, warehousing, inventory management, and other processes involved in procurement, distribution, and delivery. The goal of logistics is to deliver the right product to the right customer at the right time and place while minimizing costs and meeting customer requirements. Logistics management aims to control material and information flows efficiently and effectively across the supply chain.