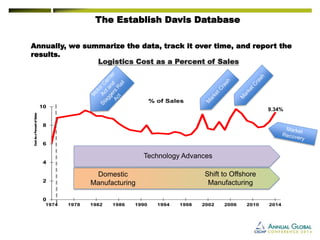

The document summarizes findings from the Establish Davis Database regarding average logistics costs and performance for companies in 2014. It finds that:

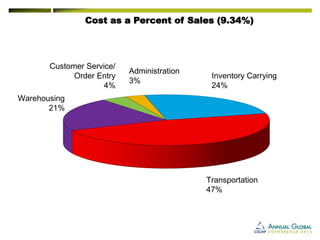

- Total logistics costs for the average company were 9.34% of sales and $69.74 per hundredweight shipped. Transportation costs made up the largest portion at 47% of total costs.

- Logistics costs increased 11% from 2013 to 2014, driven primarily by increases in transportation costs.

- Smaller companies and those with lower product values tend to have higher relative logistics costs.

- Service performance levels improved in 2014, with reductions in order cycle times and increases in on-time delivery rates.