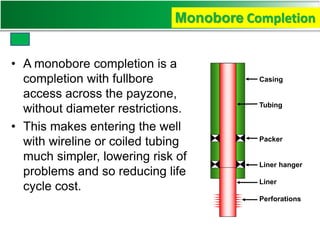

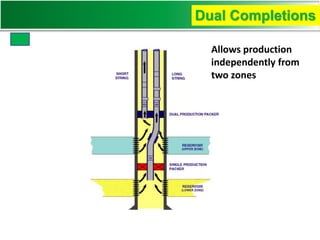

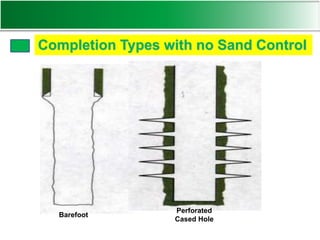

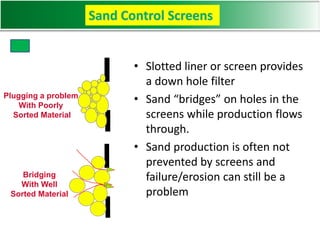

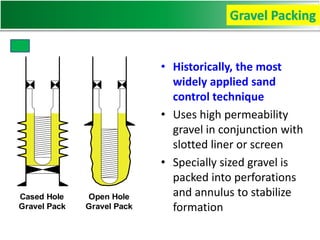

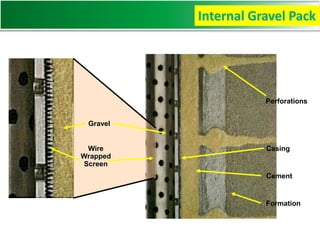

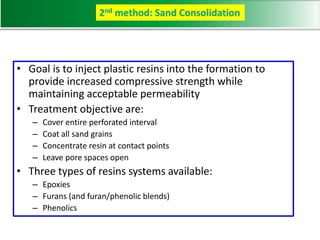

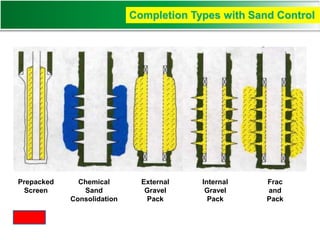

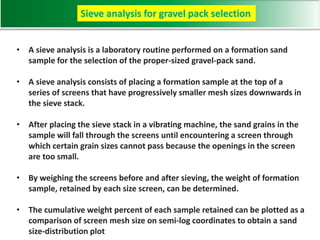

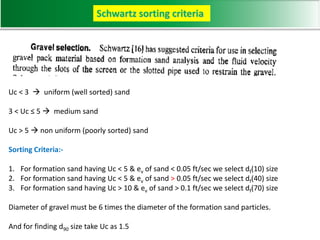

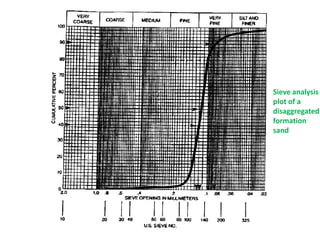

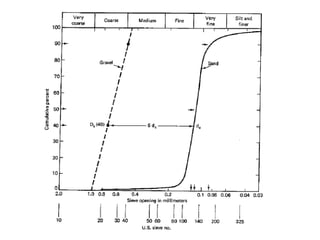

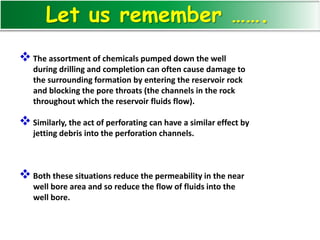

The document discusses various well completion methods and sand control techniques. It begins by explaining that well stimulation may be needed if the well's productivity has been impaired by the perforation or completion method. It then reviews different completion methods and their basic requirements to connect the reservoir, protect the casing, bring fluids to surface, provide safety measures, control sand, and provide zonal isolation. The document focuses on techniques for predicting and controlling sand production, including the use of screens, gravel packing, chemical consolidation, and frac and pack completions. It provides details on sieve analysis, gravel pack selection and sorting criteria.