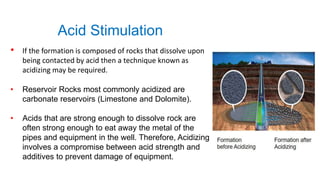

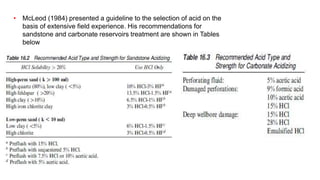

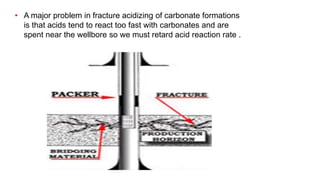

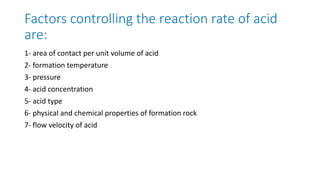

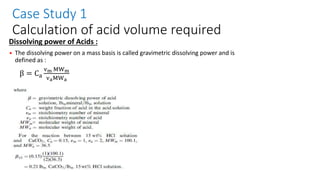

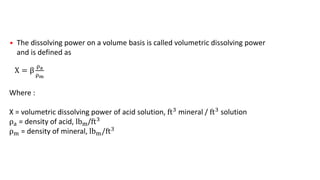

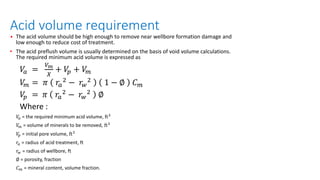

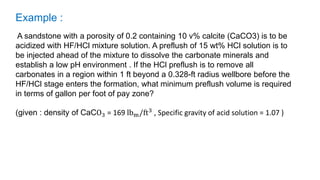

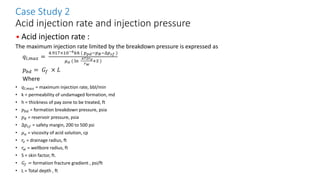

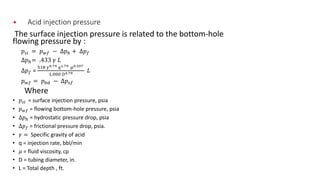

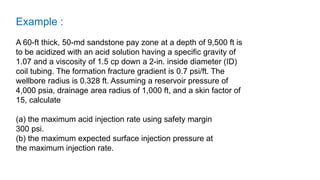

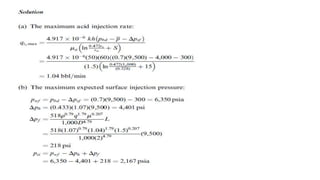

The document provides a comprehensive overview of acidizing in petroleum engineering, detailing its necessity, methods, and applications for improving well performance in low permeability formations. It covers types of acidizing, acid additives, potential problems caused by acid treatment, and guidelines for selecting appropriate acids based on formation characteristics. Additionally, case studies illustrate calculations related to acid volume requirements and injection rates for effective well stimulation.