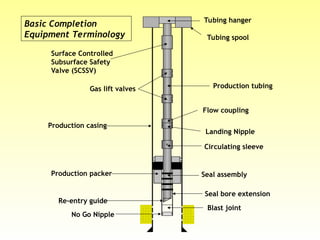

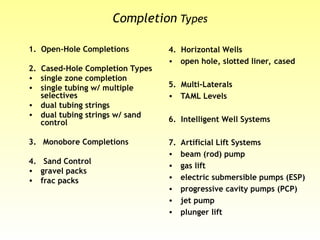

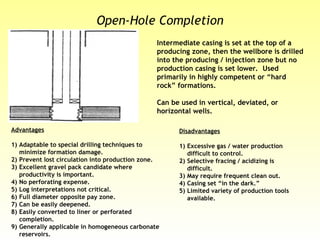

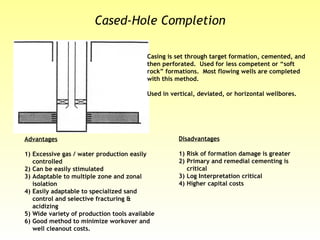

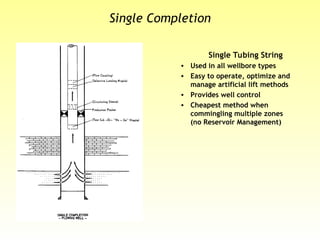

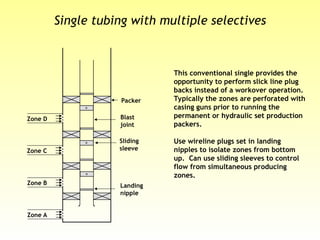

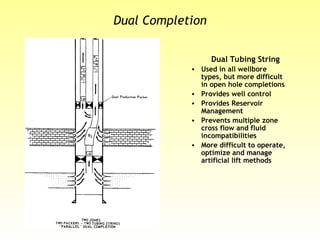

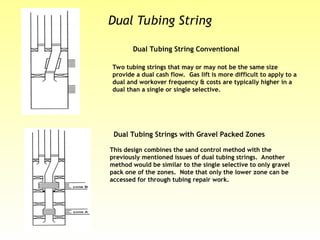

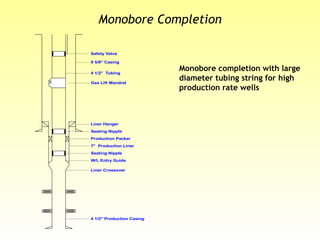

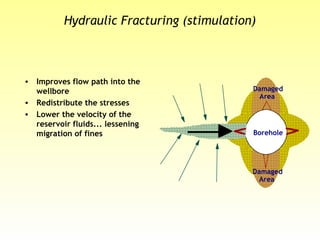

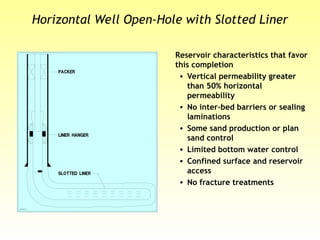

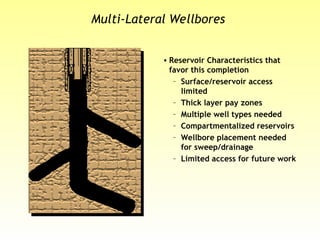

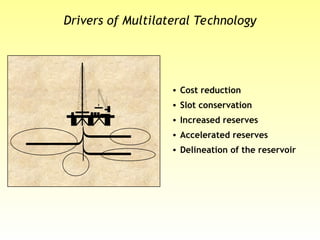

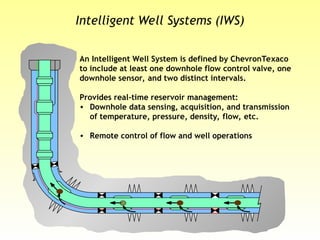

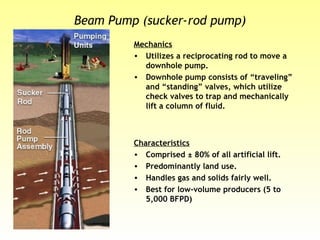

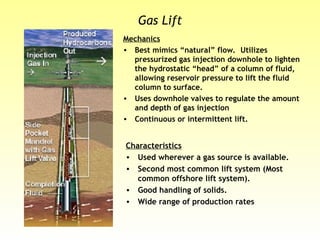

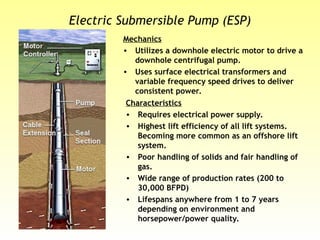

Well completion is the process of preparing a drilled well for production, involving various methods and equipment based on multiple factors like wellbore properties and fluid characteristics. The document outlines completion types such as open-hole, cased-hole, and monobore, along with their advantages and disadvantages, and discusses strategies for sand control and artificial lift systems. Additionally, it highlights the significance of intelligent well systems for real-time reservoir management.